B-site high-entropy perovskite oxide Sr0.9La0.1MO3 ceramic and preparation method thereof

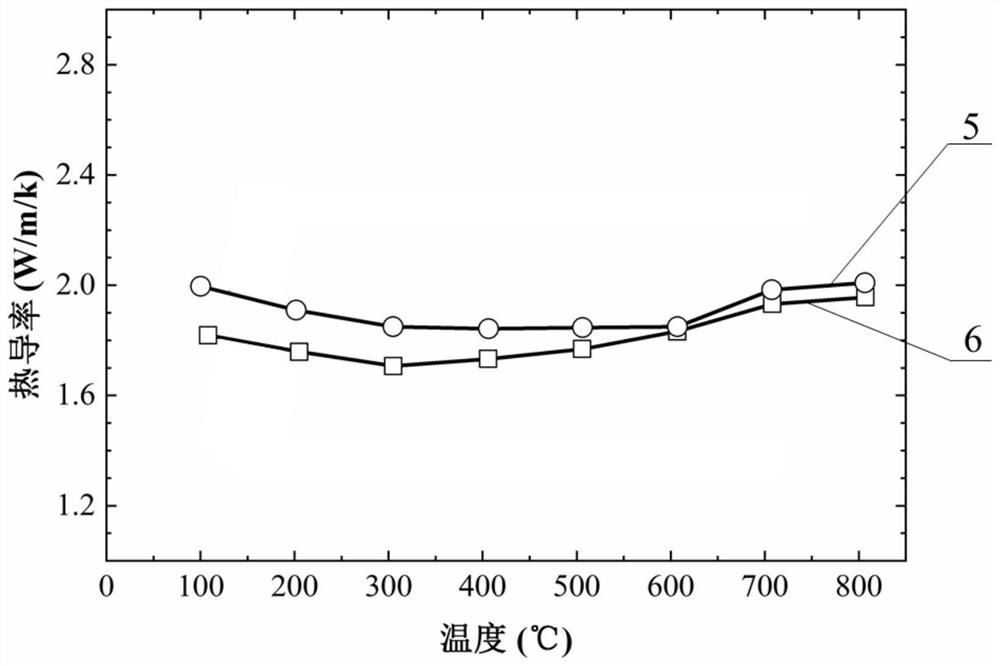

A perovskite oxide and high-entropy technology, applied in the field of high-entropy oxides, can solve the problems that cannot be applied to the field of thermoelectric materials, high-entropy perovskite oxides do not have thermoelectric properties, etc., to achieve complete grains and compact structure , The effect of reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

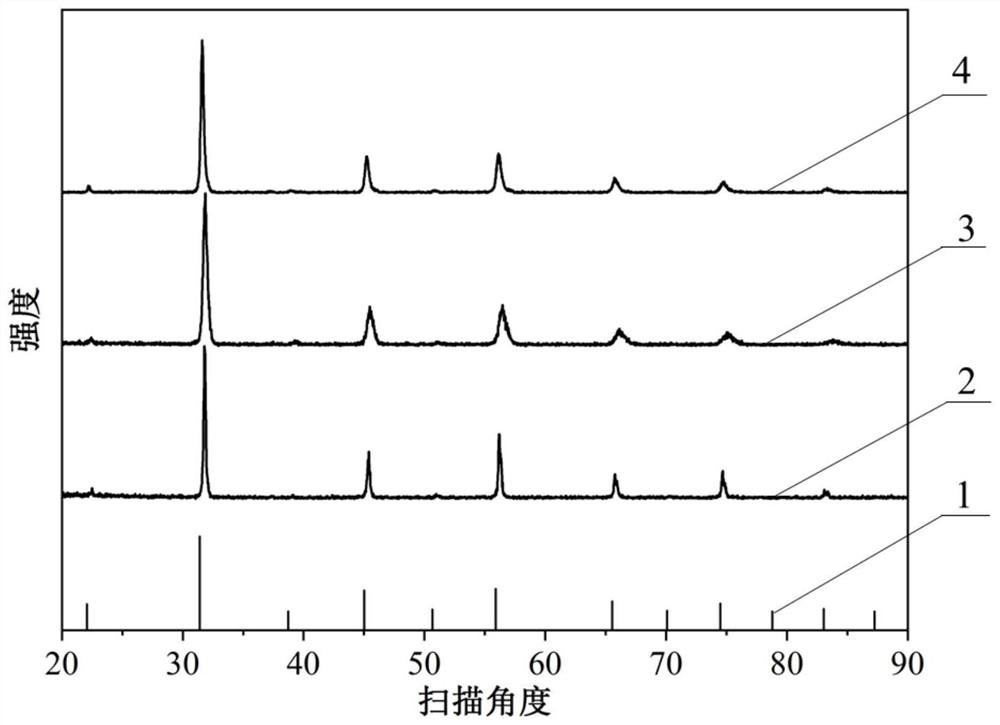

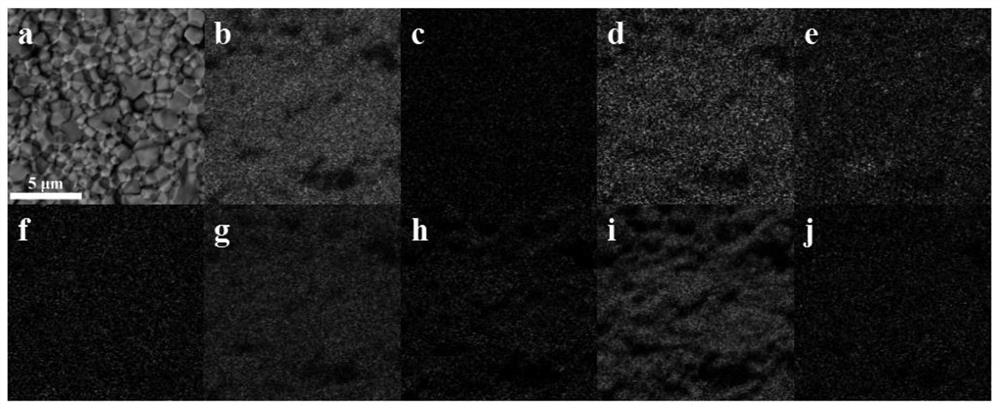

[0062] The present invention is a B-site high-entropy perovskite oxide, and its actual characteristics will be described in detail through three examples.

[0063] The chemical composition of the B-site high-entropy perovskite oxide is Sr 0.9 La 0.1 (Zr (1 / 4~1 / 6) Ti (1 / 4~1 / 6) sn (1 / 4~1 / 6) f (1 / 4~1 / 6) mn (0~1 / 6) Nb (0~1 / 6) )O 3 .

[0064] The chemical composition formula of each embodiment among the table 1 present invention

[0065] Example chemical composition 1 Sr 0.9 La 0.1 (Zr 1 / 4 Ti 1 / 4 sn 1 / 4 f 1 / 4 )O 3

2 Sr 0.9 La 0.1 (Zr 1 / 5 Ti 1 / 5 sn 1 / 5 f 1 / 5 mn 1 / 5 )O 3

3 Sr 0.9 La 0.1 (Zr 1 / 6 Ti 1 / 6 sn 1 / 6 f 1 / 6 mn 1 / 6 Nb 1 / 6 )O 3

[0066] The reagents used in each embodiment are commercially available products; analytically pure.

[0067] The preparation of the B-site high-entropy perovskite oxide Sr proposed by the present invention 0.9 La 0.1 (Zr (1 / 4~1 / 6) Ti (1 / 4~1 / 6) sn (1 / 4~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com