High-PRI constant-Mooney-viscosity natural rubber and preparation method thereof

A natural rubber, Mooney viscosity technology, applied in the field of high PRI constant Mooney viscosity natural rubber and its preparation, can solve the stability of rubber Mooney viscosity, initial plastic value, plastic retention rate, unfavorable process formulation and product performance stability , batch quality differences of natural raw rubber, etc., to achieve the effects of human and environmental friendliness, easy addition, and high plasticity retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

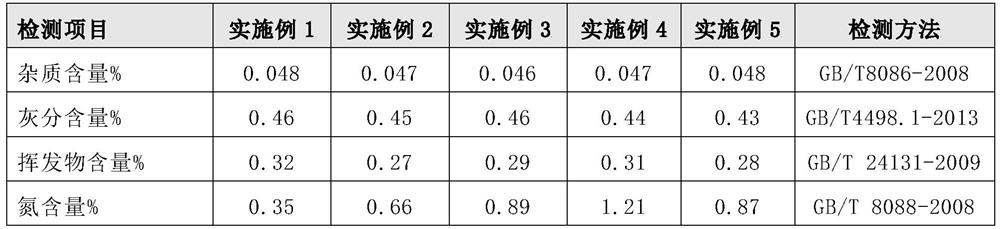

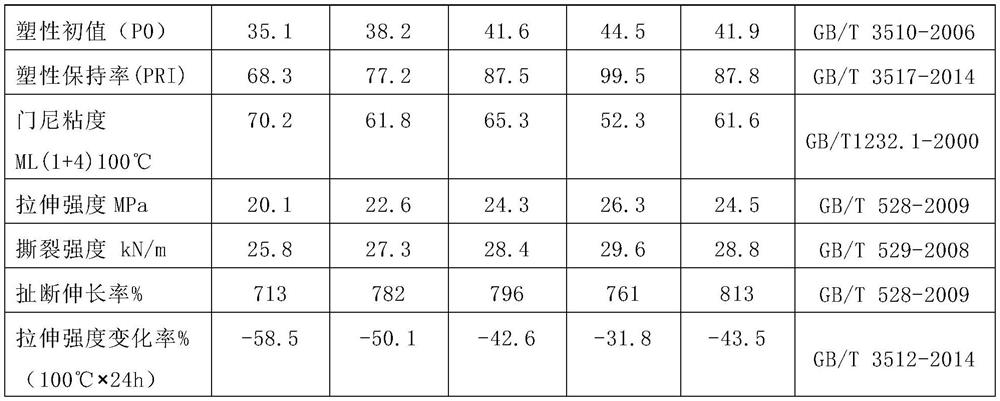

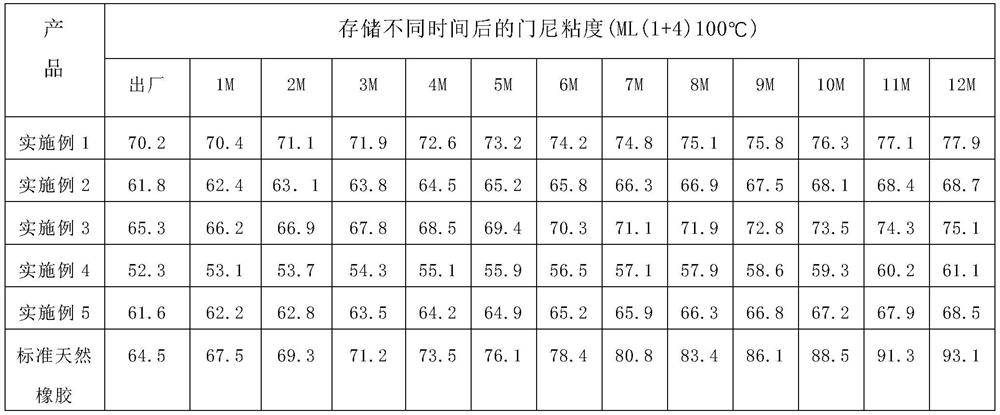

Examples

Embodiment 1

[0027] Crushing the crepe glue, rinsing out impurities, drying, and weighing for later use.

[0028] Weigh the constant viscosity agent hydrazinoethanol according to 5‰ of the weight of the crepe glue, then add it into the dry blender together with the crepe glue and mix for 4 minutes.

[0029] After cooling, briquetting and other processes, natural rubber with constant Mooney viscosity is obtained.

Embodiment 2

[0031] Weigh the whey protein by 3% of the crepe glue weight, and stir in a dry mixer for 3 minutes together with the crepe glue;

[0032] Weigh the constant viscosity agent hydrazinoethanol according to 5‰ of the weight of the crepe glue and spray it into the dry blender, and continue to stir for 4 minutes;

[0033] After cooling, briquetting and other processes, natural rubber with constant Mooney viscosity is obtained.

Embodiment 3

[0035] Crushing the crepe glue, rinsing out impurities, drying, and weighing for later use.

[0036] Weigh the whey protein by 5% of the crepe glue weight, and stir in a dry mixer for 4 minutes together with the crepe glue;

[0037] Spray the constant viscosity agent hydrazinoethanol of 2‰ of the weight of the crepe glue into the dry blender, and continue to stir for 3 minutes;

[0038] After cooling, briquetting and other processes, high PRI constant Mooney viscosity natural rubber is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com