Glass fiber reinforced PP-RCT material and preparation method thereof

A technology of PP-RCT and glass fiber, which is applied in the field of glass fiber reinforced PP-RCT material and its preparation, can solve problems such as the decline of anti-oxidation ability, and achieve improved low-temperature impact performance, high thermal oxidation resistance, and easy glass fiber content The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

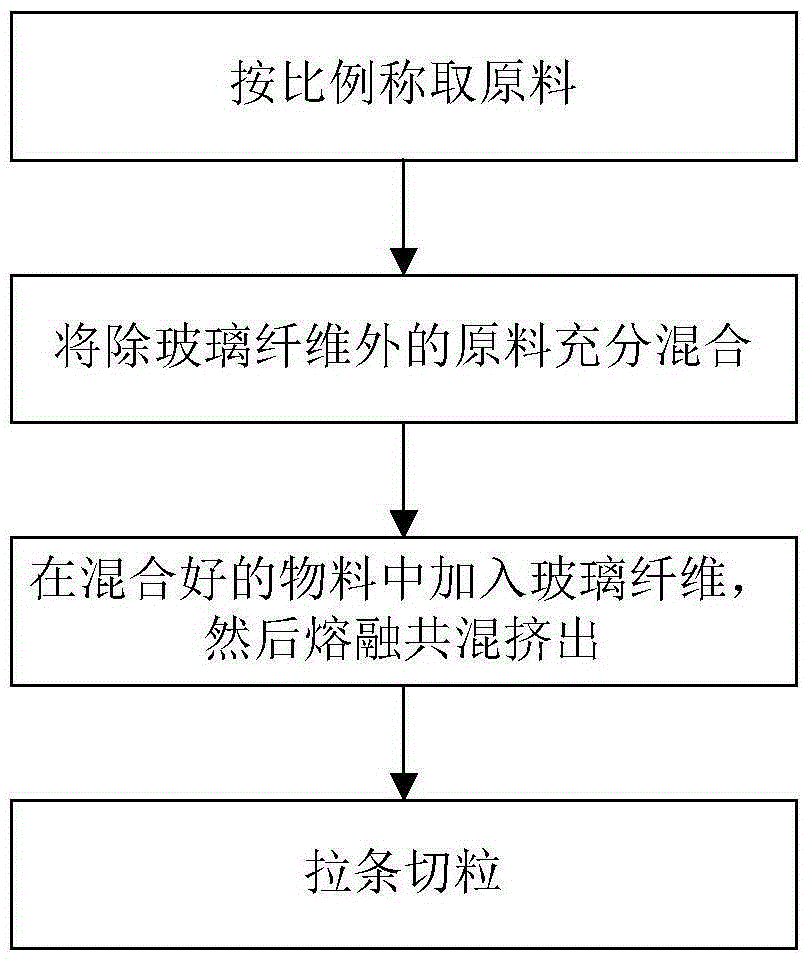

[0032] like figure 1 As shown, the preparation method of the glass fiber reinforced PP-RCT material of the present invention comprises the following steps:

[0033] 1) Weigh the raw materials of random copolymerized polypropylene, compatibilizer, glass fiber, antioxidant, light stabilizer and compound β crystal nucleating agent by weight, for use;

[0034] 2) Fully mixing the raw materials of the random copolymerized polypropylene, compatibilizer, antioxidant, light stabilizer and compound β crystal nucleating agent in parts by weight;

[0035] 3) Add glass fiber to the mixed material, and then melt, blend and extrude to obtain the glass fiber reinforced PP-RCT material.

[0036] Wherein, after step 3), it can also include:

[0037] 4) Pellet the extruded glass fiber reinforced PP-RCT material.

[0038] Wherein, in the step 2), the random copolymerized polypropylene, the compatibilizer, the antioxidant, the light stabilizer and the compound β crystal nucleating agent raw ma...

Embodiment 1

[0045] 80 parts of random copolymerized polypropylene, 5.7 parts of maleic anhydride grafted polypropylene, 3 parts of antioxidant (including 3301.5 parts of antioxidant, 10351.5 parts of antioxidant), light stabilizer (in this example, double ( 2,2,6,6-tetramethyl-4-piperidinyl)sebate) 1 part, 0.3 part of compound β crystal nucleating agent (including 0.15 part of lanthanum phthalate, N, N' -Dicyclohexyl-2,6-naphthalene diamide (DCNDCA) 0.15 parts), added to the high mixer in turn, after fully mixing for 3~5min, the mixture was added to the hopper and mixed and melted with a twin-screw extruder. In a screw extruder, 10 parts of glass fibers whose surface is treated with a silane coupling agent are mixed, then melted and extruded into strands, cooled by water, blown dry, and then cut into pellets. Among them, the screw diameter of the twin-screw extruder is 20~65mm, and the screw length-diameter ratio is 40:1. Section 220 ℃, melt temperature 215 ℃, head 205 ℃.

Embodiment 2

[0047] 65 parts of random copolymerized polypropylene, 9.2 parts of compatibilizer (polypropylene grafted with glycidyl acrylate in this example), 3.5 parts of antioxidant (including 3301.5 parts of antioxidant, 31142 parts of antioxidant) , 2 parts of light stabilizer (containing poly{[6-[(1,1,3,3-tetramethylbutyl)amino]]-1,3,5-triazine-2,4-bis[(2 ,2,6,6-Tetramethyl-4-piperidinyl)imino]-1,6-hexadiene[(2,2,6,6-tetramethyl-4-piperidinyl)imino ]} 1 part, 1 part of polysuccinic acid (4-hydroxy-2,2,6,6-tetramethyl-1-piperidine) ester), 0.3 part of compound β crystal nucleating agent (including tetramethyl 0.15 parts of lanthanum phthalate and 0.15 parts of calcium pimelic acid), added to the high mixer in turn, after fully mixing for 3~5min, the mixture was added to the hopper and mixed and melted with a twin-screw extruder, and then extruded in the twin-screw extruder. In the machine, 20 parts of glass fibers whose surface has been treated with silane coupling agent are mixed, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com