High glow-wire anti-flaming polypropylene composite and production method of polypropylene composite

A technology for burning polypropylene and composite materials, which is applied in the field of plastic flame retardancy, which can solve the problems of large amount of flame retardants, generation of harmful smoke, and decrease in tensile strength, so as to achieve good flame retardancy and promote the formation of carbon layers , the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

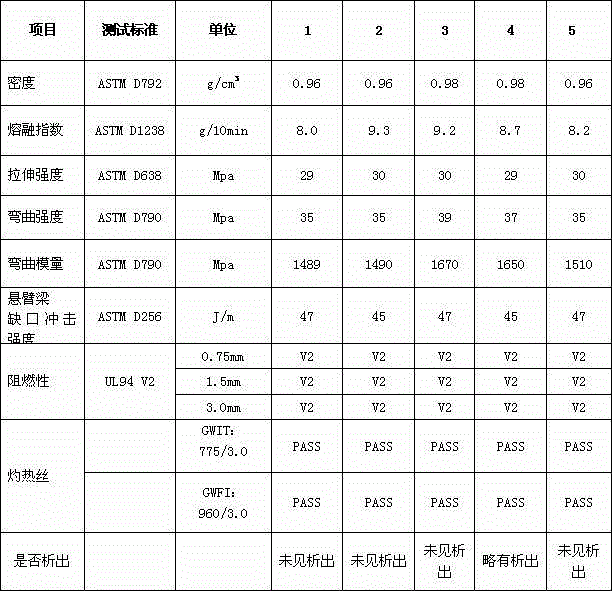

Examples

Embodiment 1

[0013] The ingredient weight composition is:

[0014] 100kg of polypropylene, 0.5kg of free radical initiator, 10kg of ground glass fiber, 3.5kg of triphenylphosphine hydrobromide wrapped in MCA, 1kg of silicone copolymer, and 0.2kg of magnesium stearate;

[0015] After the polypropylene and the compound flame retardant are weighed by weight, they are put into a high-mixer and mixed for 30s, and then added to a twin-screw extruder with a length-to-diameter ratio of 28 to 32:1 for physical melt blending, extrusion, pelletizing, and cooling. , dicing, drying, batch mixing, extruding and granulating through a twin-screw extruder, the extrusion temperature is 180 ℃ ~ 190 ℃, and sample 1 is obtained.

Embodiment 2

[0017] The ingredient weight composition is:

[0018] 100kg of polypropylene, 0.5kg of free radical initiator, 10kg of ground glass fiber, 3.5kg of polyvinylamine hydrobromide wrapped in MCA, 1kg of silicone copolymer, and 0.2kg of magnesium stearate;

[0019] After the polypropylene and the compound flame retardant are weighed by weight, they are put into a high-mixer and mixed for 30s, and then added to a twin-screw extruder with a length-to-diameter ratio of 28 to 32:1 for physical melt blending, extrusion, pelletizing, and cooling. , dicing, drying, batch mixing, extruding and granulating through a twin-screw extruder, the extrusion temperature is 180 ℃ ~ 185 ℃, and sample 2 is obtained.

Embodiment 3

[0021] The ingredient weight composition is:

[0022] 100kg of polypropylene, 0.6kg of free radical initiator, 10kg of ground glass fiber, 5kg of MCA-wrapped melamine hydrobromide, 1.5kg of silicone copolymer, and 0.4kg of magnesium stearate;

[0023] After the polypropylene and the compound flame retardant are weighed by weight, they are put into a high-mixer and mixed for 30s, and then added to a twin-screw extruder with a length-to-diameter ratio of 28 to 32:1 for physical melt blending, extrusion, pelletizing, and cooling. , dicing, drying, batch mixing, extruding and granulating through a twin-screw extruder, the extrusion temperature is 180 ℃ ~ 185 ℃, and sample 3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com