A kind of solder used on interconnection strips of solar cell modules

A technology of solar cells and interconnection strips, which is applied in the direction of electrical components, welding/cutting media/materials, circuits, etc., can solve problems affecting the efficacy of components, improve solderability, increase peel strength, reduce resistivity and Effect of Alloy Melting Point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

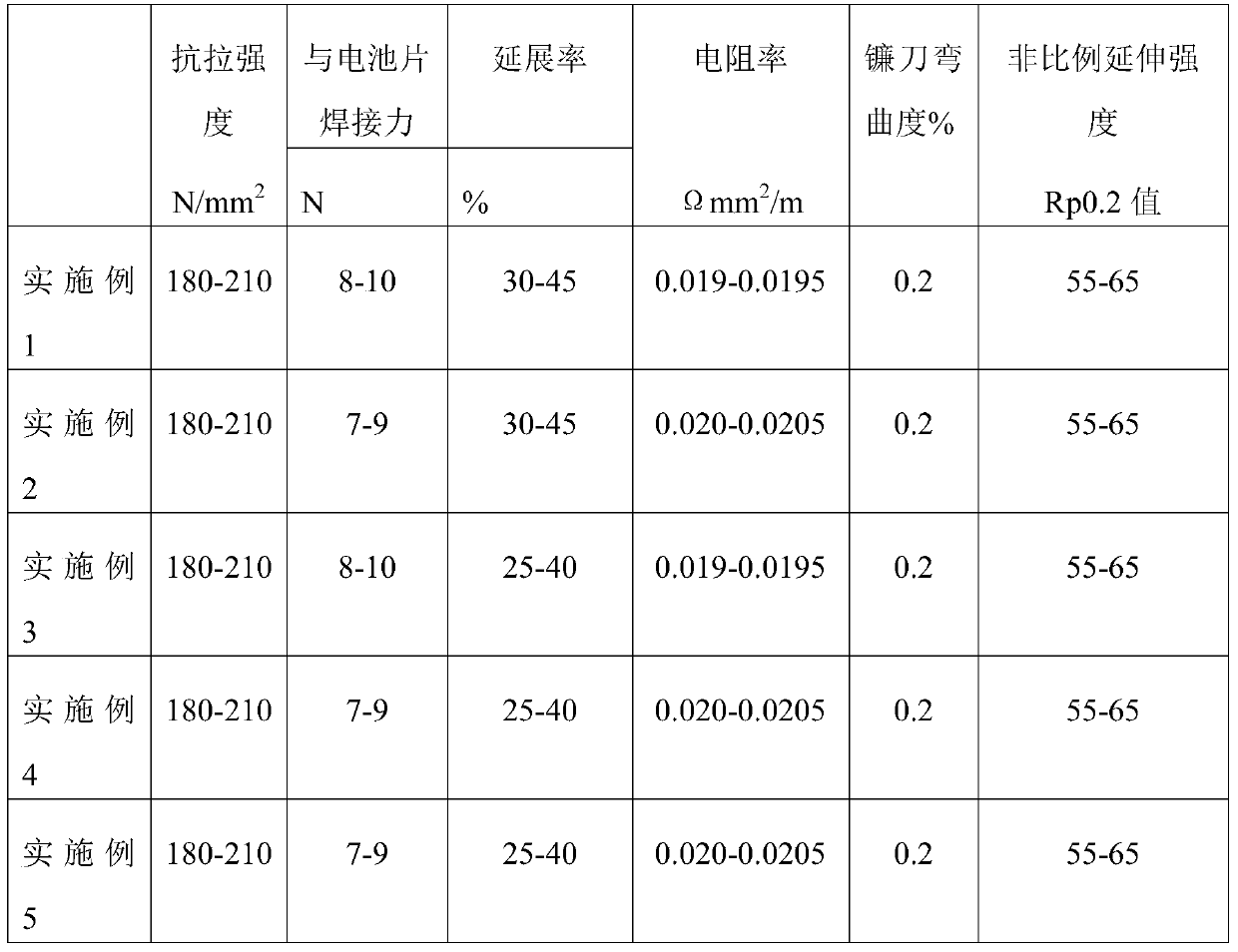

Examples

Embodiment 1

[0033] The solder used on the solar cell module interconnection strip in this embodiment is composed of the following components by weight percentage: tin: 62wt%, bismuth: 1.0wt%, antimony: 2.0wt%, gallium: 0.03wt%, indium: 1.5wt%, germanium: 1wt%, titanium: 0.1wt%, nickel: 0.5wt%, palladium: 0.005wt%, phosphorus: 0.015wt%, silver: 2.0wt%, and the balance is lead.

[0034] The above-mentioned method for preparing the solder on the solar cell module interconnection strip is as follows:

[0035] Pre-treatment: clean the oil and oxides on the surface of the substrate by alkali washing and pickling;

[0036] Hot-dip plating: immerse the substrate in a molten metal solution configured by weight percentage, and the hot-dip plating temperature is 220 degrees Celsius to form a coating;

[0037] Post-processing: surface chemical treatment, tape making, cutting and winding.

Embodiment 2

[0039] The solder used on the solar cell module interconnection strip in this embodiment is composed of the following components by weight percentage: tin: 64wt%, bismuth: 0.01wt%, antimony: 0.01wt%, gallium: 0.015wt%, indium: 0.05wt%, germanium: 0.005wt%, titanium: 0.005wt%, nickel: 0.05wt%, palladium: 0.1wt%, phosphorus: 0.03wt%, silver: 0.5wt%, and the balance is lead.

[0040] The above-mentioned method for preparing the solder on the solar cell module interconnection strip is as follows:

[0041] Pre-treatment: clean the oil and oxides on the surface of the substrate by alkali washing and pickling;

[0042] Hot-dip plating: immerse the substrate in a molten metal solution configured by weight percentage, and the hot-dip plating temperature is 240 degrees Celsius to form a coating;

[0043] Post-processing: surface chemical treatment, tape making, cutting and winding.

Embodiment 3

[0045] The solder used on the solar cell module interconnection strip in this embodiment is composed of the following components by weight percentage: tin: 62.5wt%, bismuth: 0.5wt%, antimony: 1.0wt%, gallium: 0.025wt%, indium : 1.5wt%, germanium: 0.5wt%, titanium: 0.05wt%, nickel: 0.5wt%, palladium: 0.005wt%, phosphorus: 0.15wt%, silver: 1.0wt%, and the balance is lead.

[0046] The above-mentioned method for preparing the solder on the solar cell module interconnection strip is as follows:

[0047] Pre-treatment: clean the oil and oxides on the surface of the substrate by alkali washing and pickling;

[0048] Hot-dip plating: immerse the substrate in a molten metal solution configured by weight percentage, and the hot-dip plating temperature is 220 degrees Celsius to form a coating;

[0049] Post-processing: surface chemical treatment, tape making, cutting and winding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com