Special-shaped pipe for heavy-duty-reducing rotary drilling rig mast ultrahigh-strength low-alloy guide rail

A rotary drilling rig and special-shaped pipe technology, which is applied in the field of special-shaped pipes, can solve the problems of guide rail damage and short service life, and achieve the effects of reducing weight, improving high strength, and improving low-temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

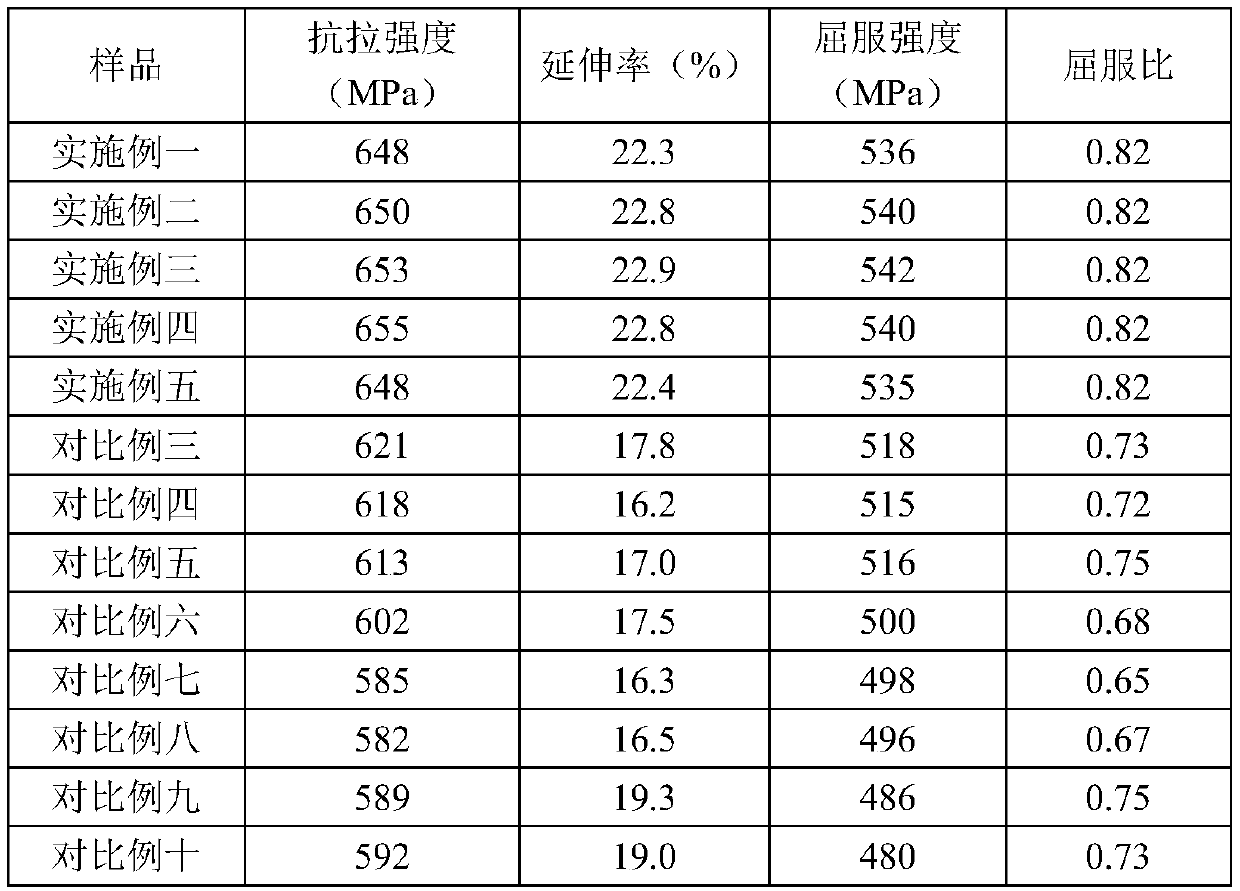

Examples

Embodiment 1

[0045] A special-shaped tube for a super-high-strength low-alloy guide rail of a heavy-duty rotary drilling rig mast, which is prepared by the following steps:

[0046] (1) Weighing according to weight percentage: C 0.08%, Si 0.35%, Mn 0.8%, P 0.015%, Cu 0.25%, Al0.012%, Mo 0.8%, B 0.03%, Ti 0.05%, Cr 0.2% and The balance is composed of Fe and impurities;

[0047] (2) Normalizing rolled special-shaped pipe at a temperature of 1030°C;

[0048] (3) Put the rolled special-shaped tube into a furnace at 890°C for 30 minutes, then quickly put it into a furnace at 600°C, keep it for 10 hours, and then air-cool it to below 150°C and take it out;

[0049] (4) inject high-temperature limestone sand into the special-shaped pipe after cooling, the temperature of limestone sand is 400 ℃, utilize hydraulic cold drawing machine to carry out cold extrusion compression deformation with the pulling force of 380 tons, and the longitudinal deformation is 60~150%;

[0050] (5) Heat treatment:

...

Embodiment 2

[0054] A special-shaped tube for a super-high-strength low-alloy guide rail of a heavy-duty rotary drilling rig mast, which is prepared by the following steps:

[0055] (1) Weighing according to weight percentage: C 0.09%, Si 0.38%, Mn 1.0%, P 0.018%, Cu 0.30%, Al0.016%, Mo 0.8%, B 0.03%, Ti 0.08%, Cr 0.3% and The balance is composed of Fe and impurities;

[0056] (2) Normalizing rolled special-shaped pipe at a temperature of 1050°C;

[0057] (3) Put the rolled special-shaped tube into a furnace at 900°C for 35 minutes, then quickly put it into a furnace at 610°C, keep it warm for 10 hours, and then air-cool it to below 150°C and take it out;

[0058] (4) inject high-temperature limestone sand into the special-shaped pipe after cooling, the temperature of limestone sand is 400 ℃, utilize hydraulic cold drawing machine to carry out cold extrusion compression deformation with the pulling force of 400 tons, and the longitudinal deformation is 60~150%;

[0059] (5) Heat treatmen...

Embodiment 3

[0063] A special-shaped tube for a super-high-strength low-alloy guide rail of a heavy-duty rotary drilling rig mast, which is prepared by the following steps:

[0064] (1) Weighing according to weight percentage: C 0.095%, Si 0.40%, Mn 1.1%, P 0.020%, Cu 0.32%, Al0.022%, Mo 1.0%, B 0.045%, Ti 0.10%, Cr 0.35% and The balance is composed of Fe and impurities;

[0065] (2) Normalizing rolled special-shaped pipe at a temperature of 1080°C;

[0066] (3) Put the rolled special-shaped tube into a furnace at 900°C for 35 minutes, then quickly put it into a furnace at 620°C, keep it warm for 10-12 hours, and then air-cool it to below 150°C and take it out;

[0067] (4) inject high-temperature limestone sand into the special-shaped pipe after cooling, the temperature of limestone sand is 420 ℃, utilize hydraulic cold drawing machine to carry out cold extrusion compression deformation with the pulling force of 450 tons, and the longitudinal deformation is 60~150%;

[0068] (5) Heat tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com