Disc type automatic bale plucker

A cotton catching machine, disc-type technology, applied in the field of disc-type automatic cotton catching machines, can solve the problems of cleaning troubles, cotton bundle winding, etc., and achieve the effect of convenient cleaning work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

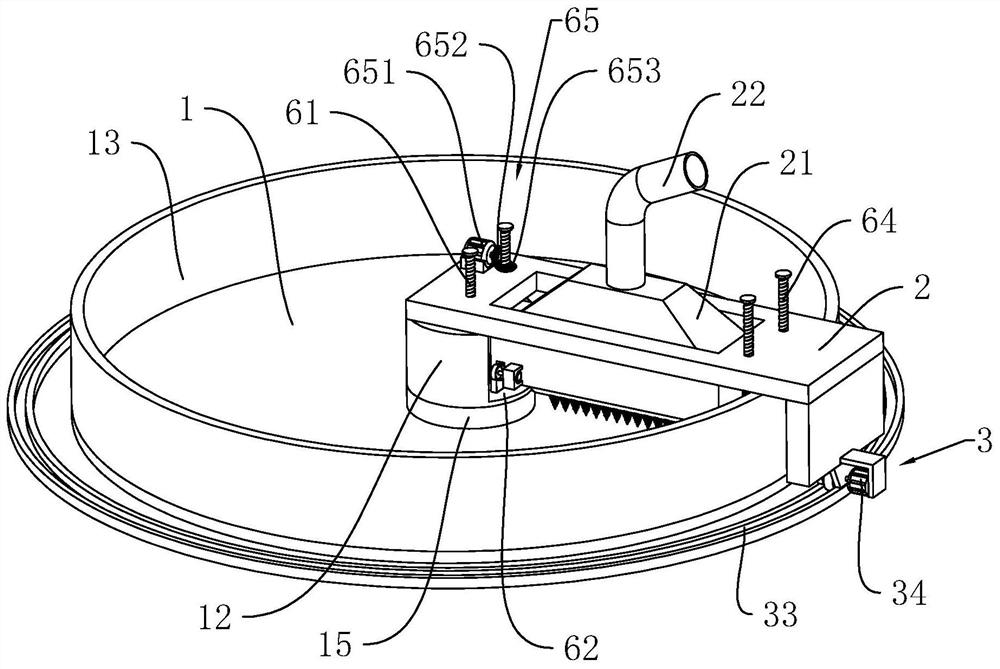

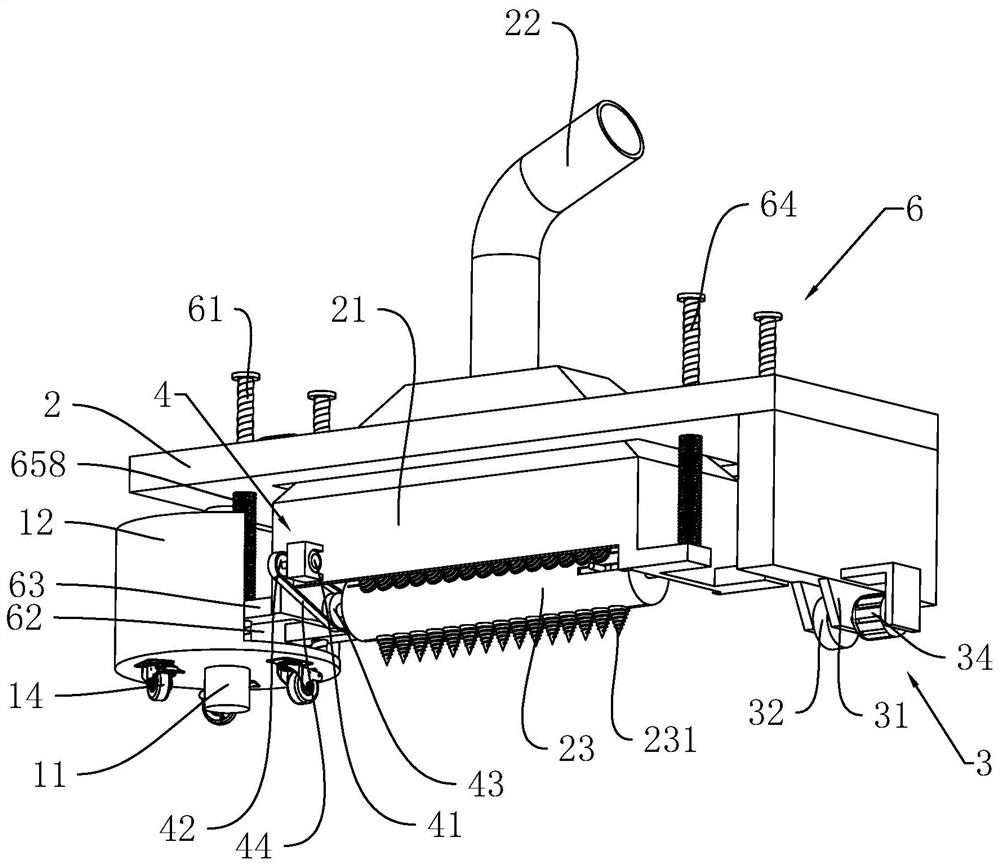

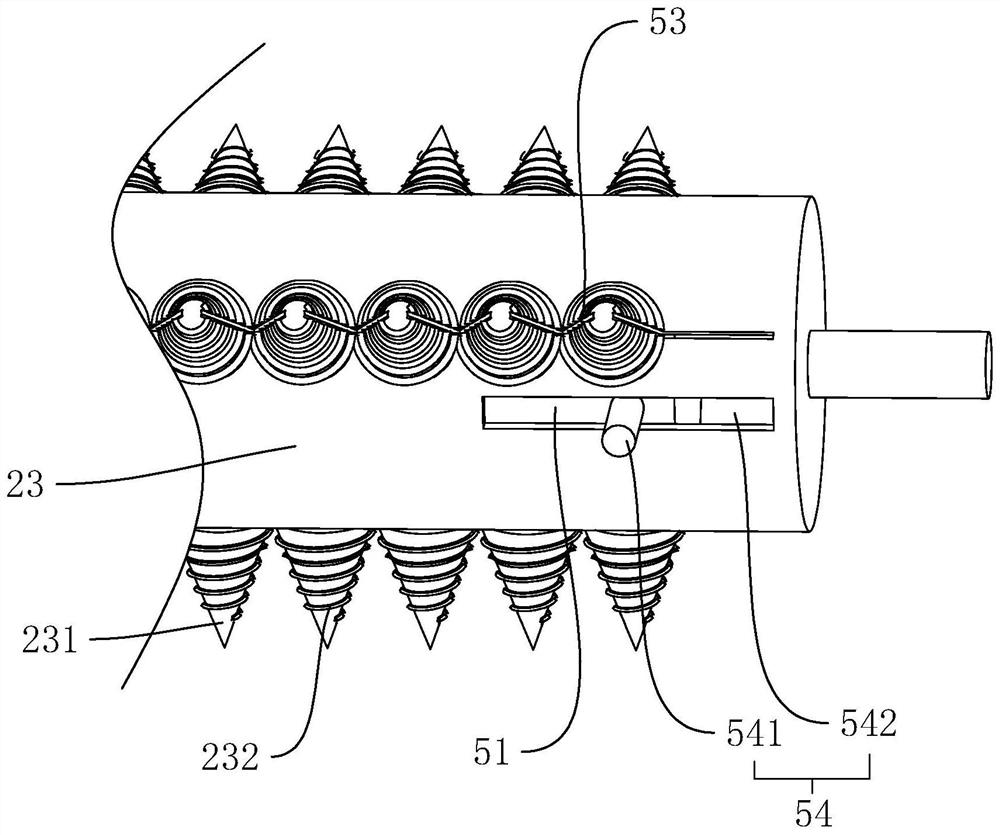

[0037] The following is attached Figure 1-6 The application is described in further detail.

[0038] The embodiment of the present application discloses a disc type automatic cotton picking machine. refer to figure 1 and figure 2 , a disc-type automatic plucking machine includes a horizontal bottom plate 1, the bottom plate 1 is arranged in a circle, and the bottom plate 1 is located at the center of the circle and is connected with a vertical central shaft 11 through bearing rotation. And the base plate 1 is provided with a cylindrical inner ring wall panel 12 , and the inner ring wall panel 12 is sleeved on the central axis 11 , and the inner ring wall panel 12 and the central axis 11 are arranged coaxially. Three rollers 14 are arranged at the lower end of the inner ring wallboard 12, and the rollers 14 roll and rub against the upper surface of the bottom plate 1, and the three rollers 14 are arranged equidistantly along the circumference of the inner ring wallboard 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com