Rapid positioning device for magnetic steel of magnetizing flywheel

A technology of positioning device and magnetic flywheel, which is applied in the direction of connecting components, material gluing, mechanical equipment, etc., can solve the problem of not being able to accurately locate 4 magnetic steels, and achieve the effect of guaranteeing processing accuracy and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

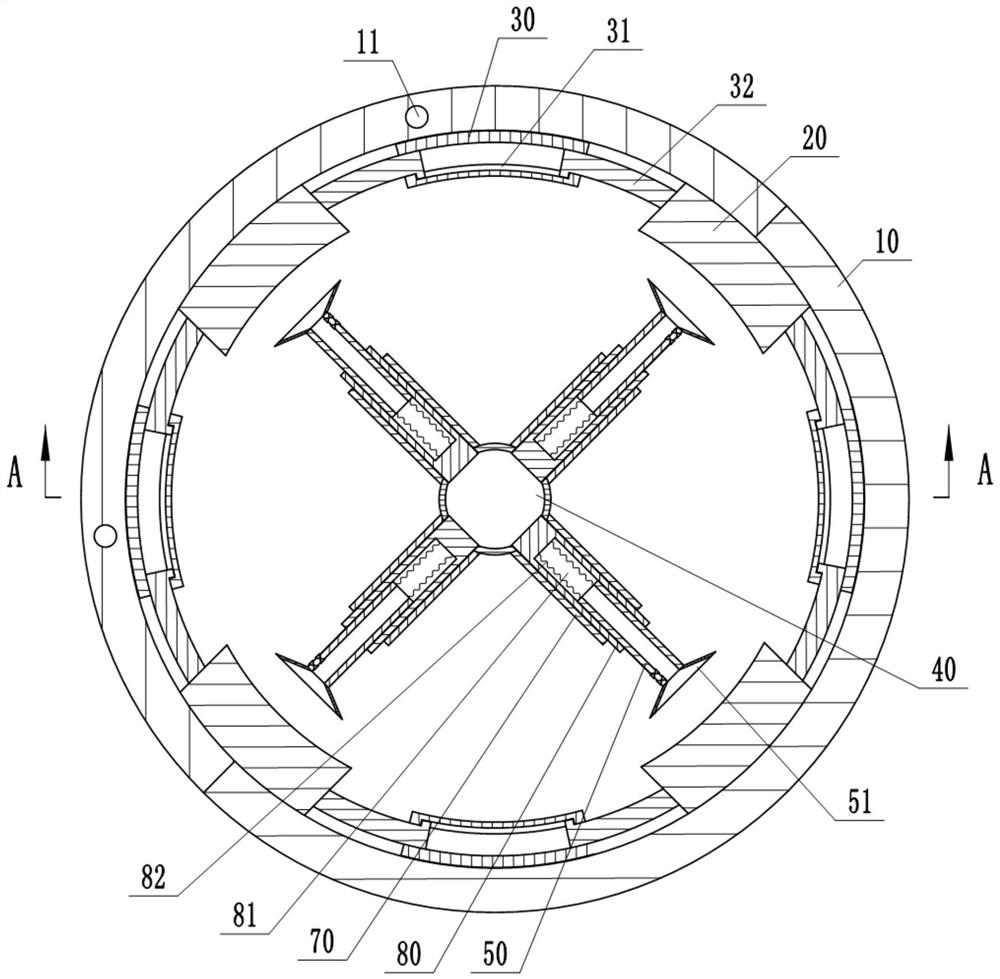

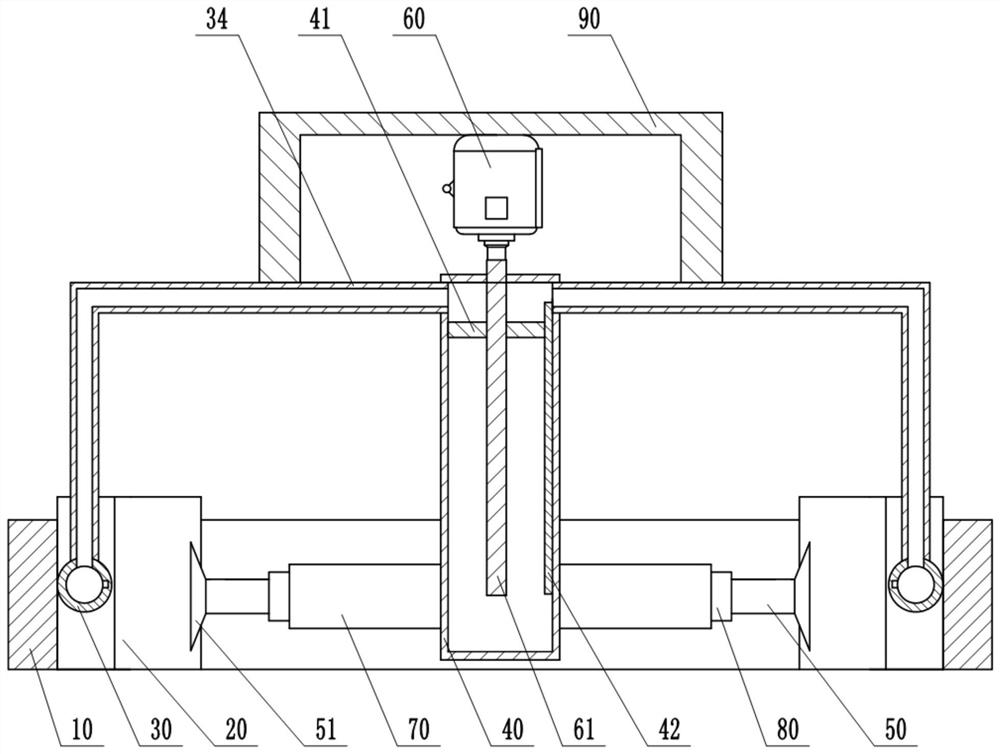

[0020] The reference signs in the drawings of the description include: semi-circular ring 10, socket 11, magnetic steel 20, arc-shaped tube 30, limit groove 31, arc-shaped clamp block 32, L-shaped tube 34, main pipe 40, piston 41, Protruding line 42, sleeve 50, suction cup 51, rotating rod 61, motor 60, moving column 80, concave cavity 81, elastic member 82, fixed cylinder 70, bracket 90.

[0021] This embodiment is basically as figure 1 , figure 2 Shown: magnetized flywheel magnetic steel rapid positioning device, including workbench, support 90, annular ring, positioning mechanism, feeding mechanism and power mechanism. The diameter of the annular ring is smaller than the diameter of the cavity of the flywheel, and the annular ring includes two symmetrically arranged semicircular rings 10, one of which is welded on the workbench, and the other semicircular ring 10 is slidably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com