Combined valve rod sealing structure

A technology of sealing structure and combined sealing, applied in the direction of valve shell structure, shaft seal, valve details, etc., can solve the problems of insufficient packing seal pressing force, damage to packing seal pressing force, damage to lip seal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

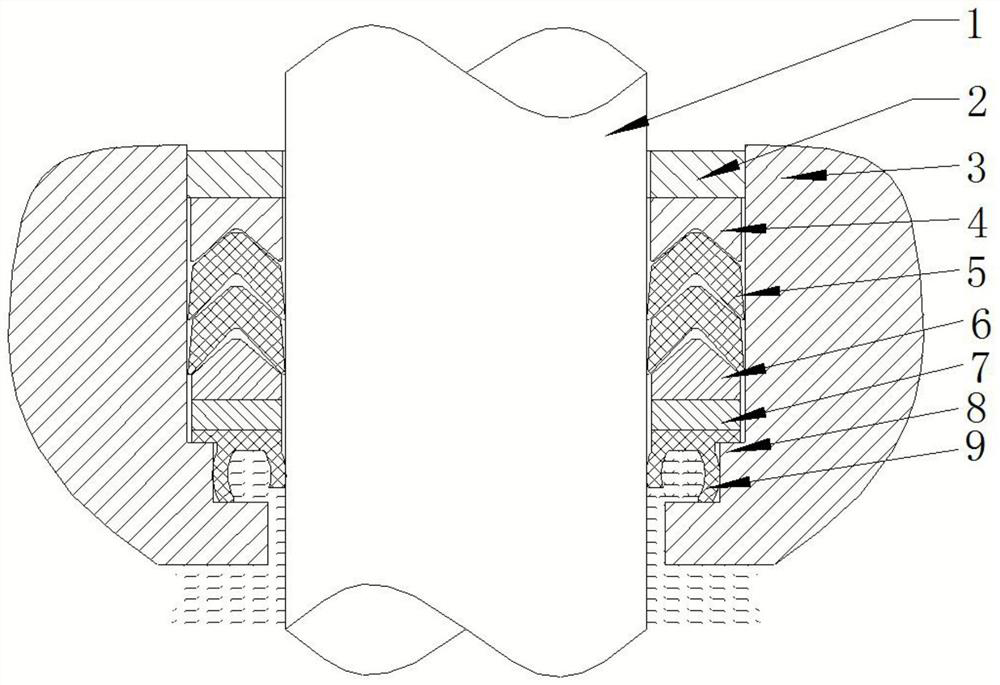

[0024] Such as figure 1 As shown: this embodiment provides a combined valve stem sealing structure 100, including packing gland 2, lip sealing ring 9, packing sealing assembly and isolation elements, between the valve stem 1 and the valve body 3 in order from top to bottom A packing gland 2 , a packing seal assembly, an isolation element and a lip sealing ring 9 are pierced, and the isolation element is clamped on the valve body 3 or the valve stem 1 . The packing gland 2 is threadedly connected with the valve stem 1, or the valve body 3 is additionally bolted to compress the packing gland 2.

[0025] The isolation element is a metal retaining ring 7, and the valve body 3 or the valve stem 1 is provided with a boss 8, and the metal retaining ring 7 is snapped on the boss 8, and if the lip sealing ring 9 has lugs, the lugs are also snapped On the boss 8, it is convenient to press and fix the lip sealing ring 9. Between the packing seal components of the isolation element, the...

Embodiment 2

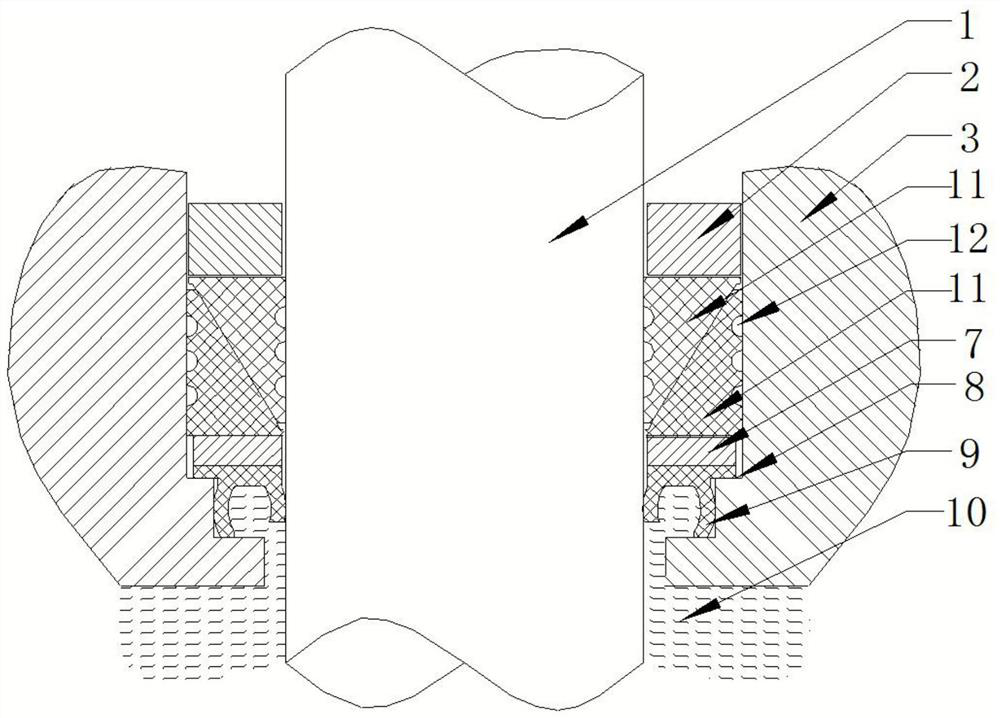

[0029] Such as figure 2 As shown: this embodiment provides a combined valve stem sealing structure 100, the only difference from the structure in the first embodiment is that the packing seal assembly is a wedge-shaped combined seal, and the wedge-shaped combined seal includes two matching wedge-shaped seal rings 11 , there are several ring grooves 12 on the contact surface between the wedge-shaped sealing ring 11 and the valve body 3 or valve stem 1, so that the contact surface changes from surface contact to line contact, and the sealing material can be filled with greater deformation under the same force For local gaps, the ring groove 12 can also divide one sealing surface into multiple seals to improve the sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com