Optical system, camera module and electronic equipment

An optical system and related technology, applied in the field of optical system, camera module and electronic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

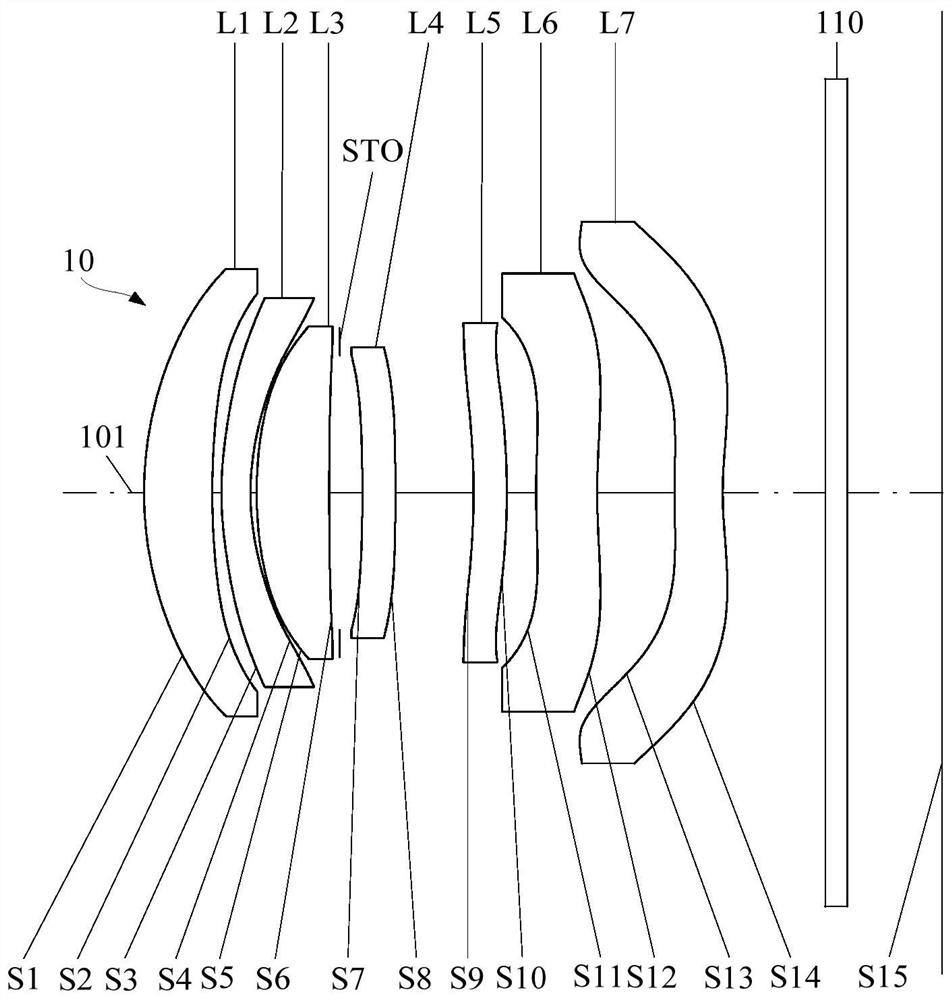

[0095] refer to figure 1 and figure 2 , in the first embodiment, the optical system 10 includes a first lens L1 with positive refractive power, a second lens L2 with negative refractive power, and a third lens L2 with positive refractive power from the object side to the image side along the optical axis 101. Lens L3, aperture stop STO, fourth lens L4 with negative refractive power, fifth lens L5 with negative refractive power, sixth lens L6 with negative refractive power, and seventh lens L7 with negative refractive power. figure 2 The longitudinal spherical aberration diagram, astigmatism diagram and distortion diagram of the optical system 10 in the first embodiment are included, and the reference wavelength of the astigmatism diagram and distortion diagram in each of the following embodiments is 555 nm.

[0096] The object side S1 of the first lens L1 is convex at the near optical axis, and the image side S2 is concave at the near optical axis; the object side S1 is con...

no. 2 example

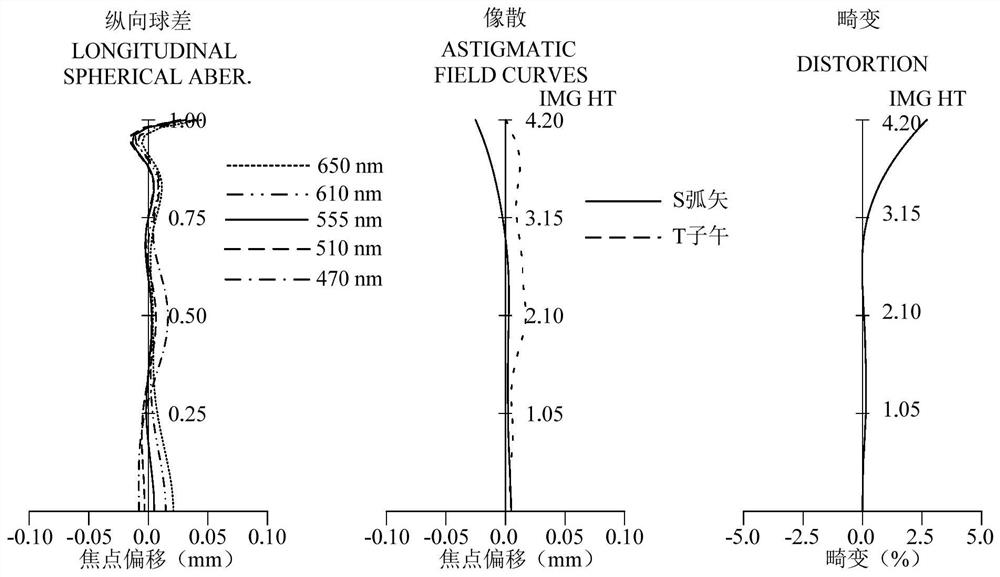

[0123] refer to image 3 and Figure 4 , in the second embodiment, the optical system 10 includes a first lens L1 with positive refractive power, a second lens L2 with negative refractive power, and a third lens L2 with positive refractive power from the object side to the image side along the optical axis 101. Lens L3, aperture stop STO, fourth lens L4 with negative refractive power, fifth lens L5 with positive refractive power, sixth lens L6 with negative refractive power, and seventh lens L7 with negative refractive power. Figure 4 The longitudinal spherical aberration diagram, astigmatism diagram and distortion diagram of the optical system 10 in the second embodiment are included.

[0124] The object side S1 of the first lens L1 is convex at the near optical axis, and the image side S2 is concave at the near optical axis; the object side S1 is convex near the circumference, and the image side S2 is concave near the circumference.

[0125] The object side S3 of the seco...

no. 3 example

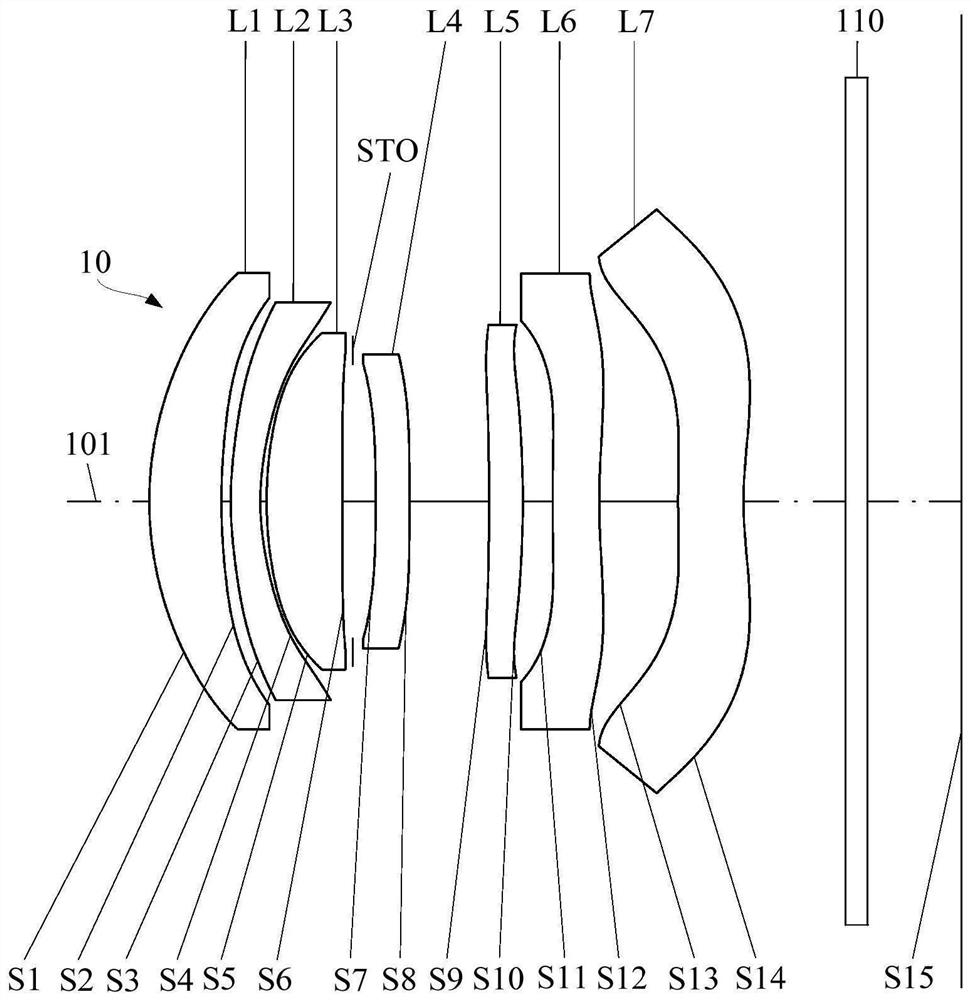

[0141] refer to Figure 5 and Figure 6 , in the third embodiment, the optical system 10 sequentially includes a first lens L1 with positive refractive power, a second lens L2 with negative refractive power, and a third lens L2 with positive refractive power along the optical axis 101 from the object side to the image side. Lens L3, aperture stop STO, fourth lens L4 with positive refractive power, fifth lens L5 with positive refractive power, sixth lens L6 with negative refractive power, and seventh lens L7 with negative refractive power. Figure 6 The longitudinal spherical aberration diagram, astigmatism diagram and distortion diagram of the optical system 10 in the third embodiment are included.

[0142] The object side S1 of the first lens L1 is convex at the near optical axis, and the image side S2 is concave at the near optical axis; the object side S1 is convex near the circumference, and the image side S2 is concave near the circumference.

[0143] The object side S3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com