Edge grabbing method, edge grabbing system, machining equipment and machining system

A technology of processing equipment and processing system, which is applied in the field of edge grasping method, processing equipment and processing system, and edge grasping system, and can solve the problems that color distinction cannot realize automatic positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a method for grabbing edges, comprising the following steps:

[0047] S0: Obtain offset compensation parameters;

[0048] S1: placing the workpiece on the workbench 5, wherein the workpiece has an edge transition structure 31;

[0049] S2: The light source is irradiated vertically on the workpiece after being shaped by the light shaping unit;

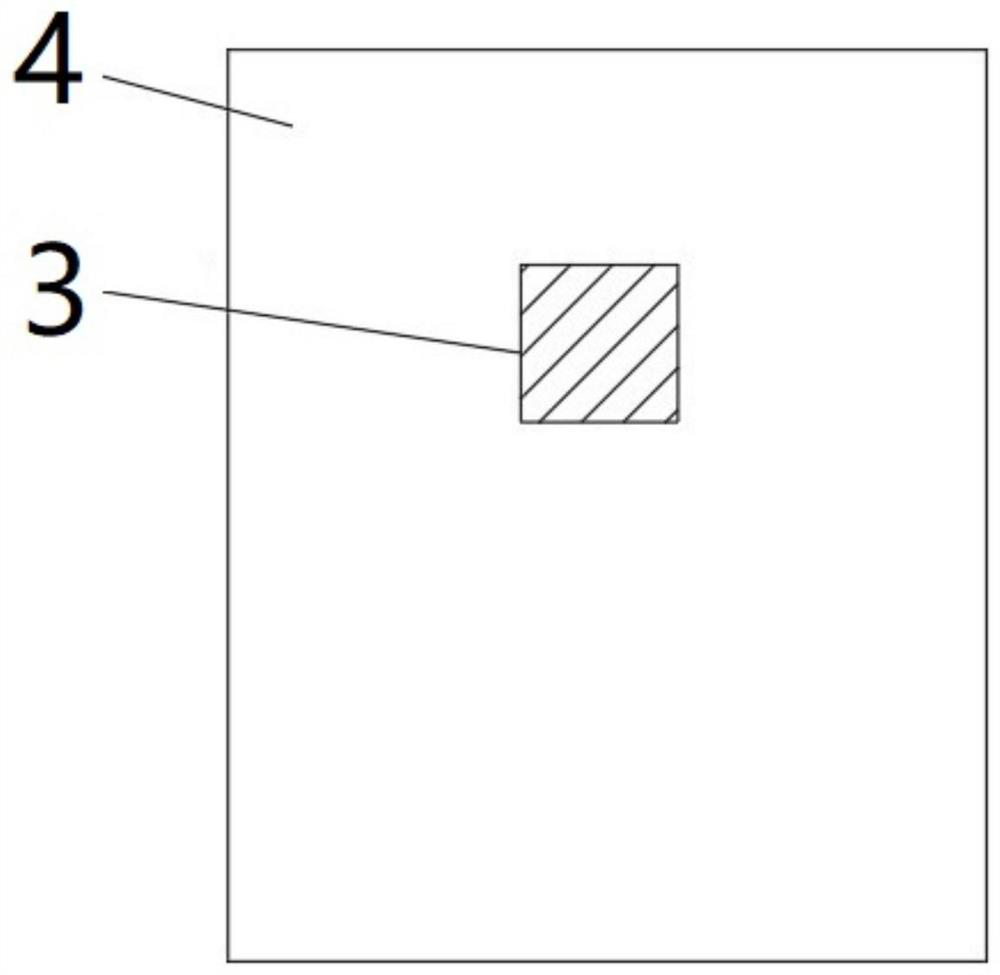

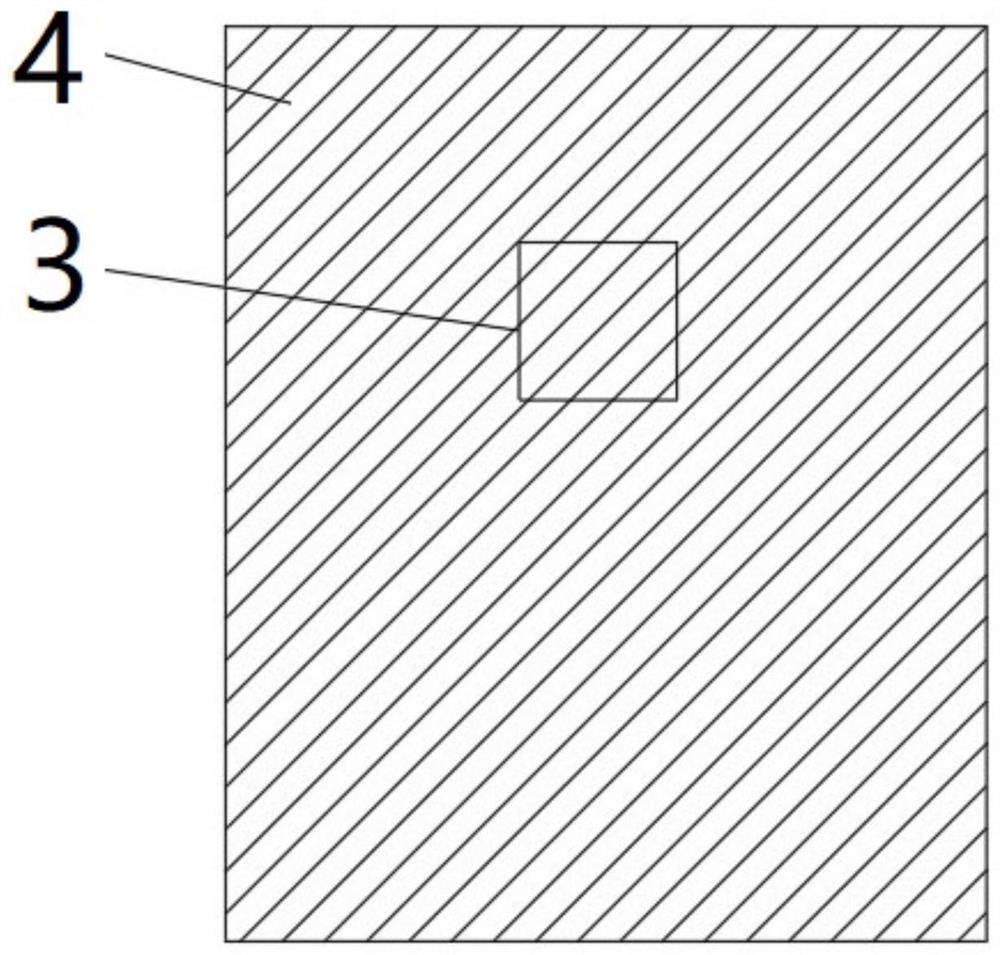

[0050] S3: if image 3 , Figure 4 , Figure 6 to Figure 8 As shown, the light irradiated on the workpiece is reflected to the visual element 7 , the light contrast is obtained through the visual element 7 , and the position of the edge transition structure 31 is determined by the dark area of the light contrast.

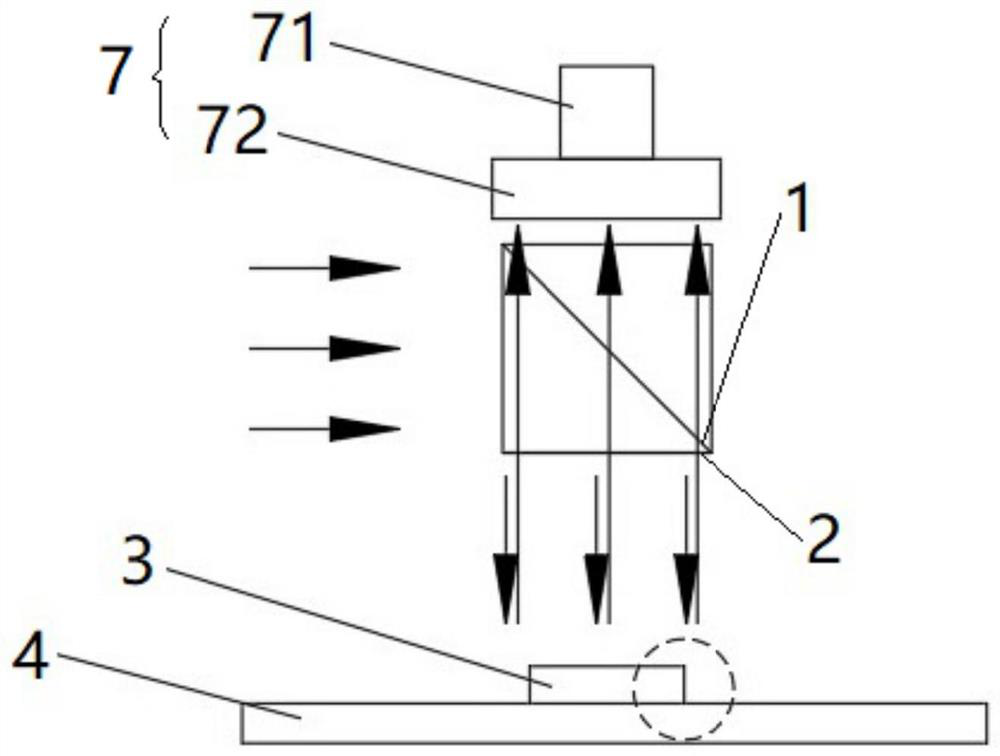

[0051] The light shaping part is a transparent lens 1, and the transparent lens 1 can be fixedly installed by the fixing part 2. Specifically, the reflective surface of the transparent lens 1 is set at an angle of 45 degrees, of course, the reflective surface of the transparent lens 1 ca...

Embodiment 2

[0060] This embodiment provides an edge grabbing system, including image 3 The workbench 5, the light shaping part and the visual part 7 are arranged in sequence from bottom to top, and the workpiece is grasped by the edge grasping method in the first embodiment. The visual component 7 may include a CCD 71 and an external lens 72 , or may not include the external lens 72 , or may be other visual components 7 .

Embodiment 3

[0062] This embodiment provides a processing device, including the edge gripping system in Embodiment 2. The processing equipment may be light processing equipment or other processing equipment. For details, see Figure 9 , the light processing equipment includes a stand 9, a base 6, a light processing device 8, and the edge gripping system in Embodiment 2, wherein the light processing device 8 is fixed on the stand 9, and the visual part 7 is fixed on the light processing device 8 Above, a workbench 5 is formed on the base 6 .

[0063] When the light processing equipment is working, the edge gripping system moves and grips the workpiece. Due to the limitation of the field of view of the edge-grabbing system, the edge-grabbing system can only obtain part of the edge of the first workpiece, and therefore only obtains the approximate position of the first workpiece. The edge gripping system is then moved along the vicinity of the edge of the first workpiece to determine the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com