Light strip refinement method for linear laser skin opposite seam measurement

A line laser and light strip technology, applied in the field of image processing, can solve the problems of fuzzy key features of the image and the inability to accurately extract the center of light strips, etc., to achieve the effects of preserving integrity, improving anti-noise ability, and accelerating the iterative process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0047] In the description of this patent, it should be noted that, unless otherwise clearly specified and limited, the terms "installation", "connection", "connection", and "setting" should be understood in a broad sense, for example, it can be fixed connection, setting , can also be detachably connected and set, or integrally connected and set. Those of ordinary skill in the art can understand the specific meanings of the above terms in this patent according to specific situations.

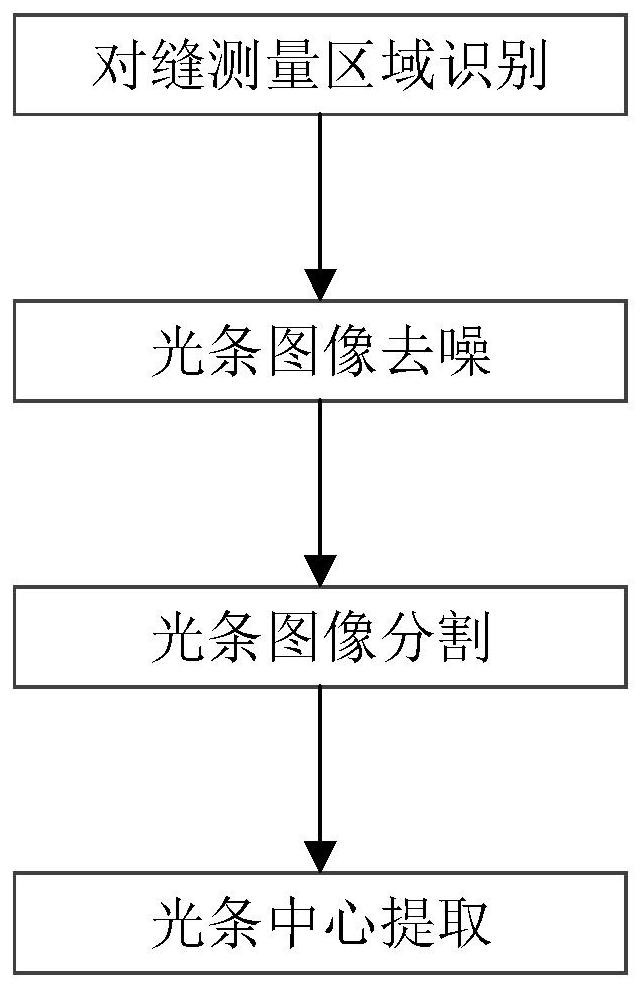

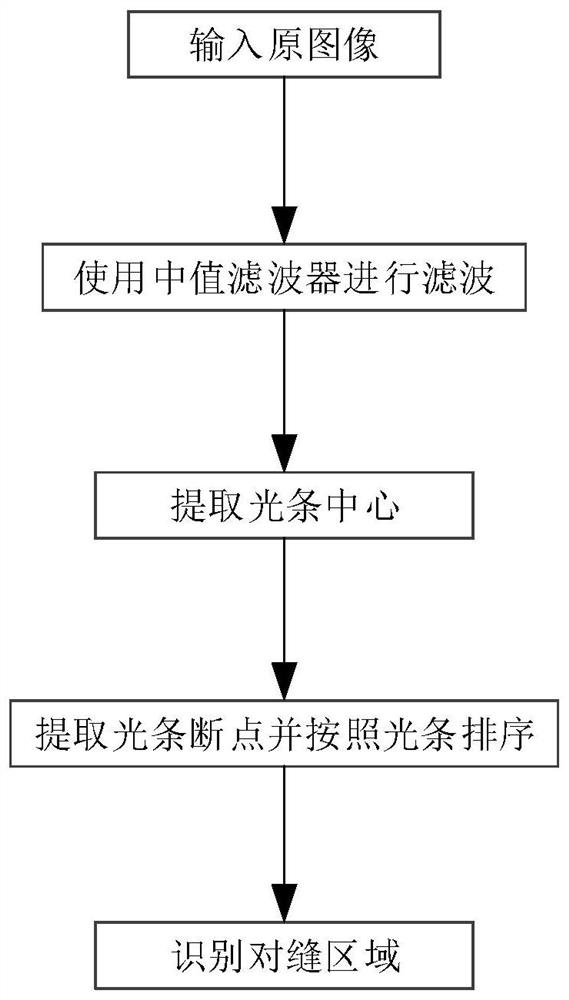

[0048] A light strip thinning method for line laser skin to seam measurement, comprising the following steps:

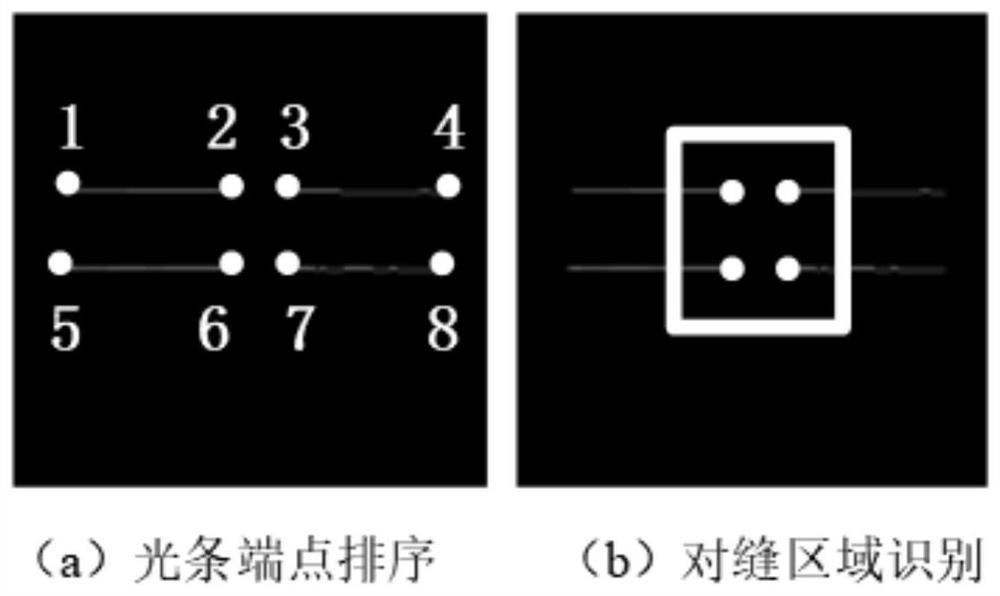

[0049] S1: Identify the gap measurement area according to the serial number of the end point of the light bar;

[0050]S2: Identify the skin butt seam area based on the end point of the light bar;

[0051] S3: Using an adaptive full variational filter fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com