Surface defect detection method

A defect detection and defect technology, applied in the field of image processing, can solve problems such as increasing the difficulty of training, and achieve the effect of improving recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

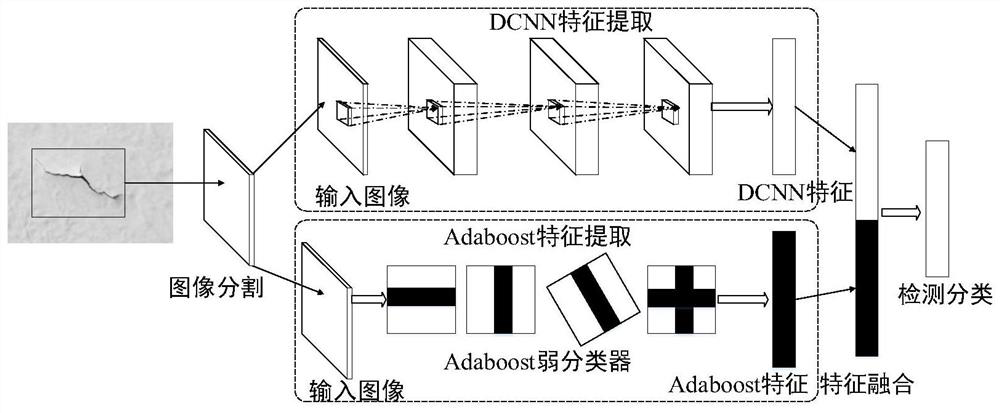

[0037] Such as figure 1 As shown, a surface defect detection method collects the image of the defect through the camera; then the collected image is segmented, and the segmented sub-images are respectively input into the DCNN network and the Adaboost network, and the DCNN network and the Adaboost network are respectively Output DCNN features and Adaboost features, and finally normalize and fuse the features and use a classifier to classify them, and output the type of surface defect and the probability of belonging to this type.

[0038] The camera is fixed directly above the object, and the camera is at an angle of 30° downward to the vertical direction.

[0039] The steps to segment the collected images are:

[0040] S1 Since the surface defects of the target are generally obvious, the image is preprocessed first by edge operators to detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com