Stator bar transposition method for formed transposition winding permanent magnet synchronous motor

A permanent magnet synchronous motor and stator bar technology, applied in the direction of the shape/style/structure of the winding conductor, can solve the problems of the decrease of the circulation suppression effect, the decrease of the space occupied by the slot, and the decrease of the motor slot full rate, so as to reduce the The effect of heat generation, increasing tank full rate, and reducing circulation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

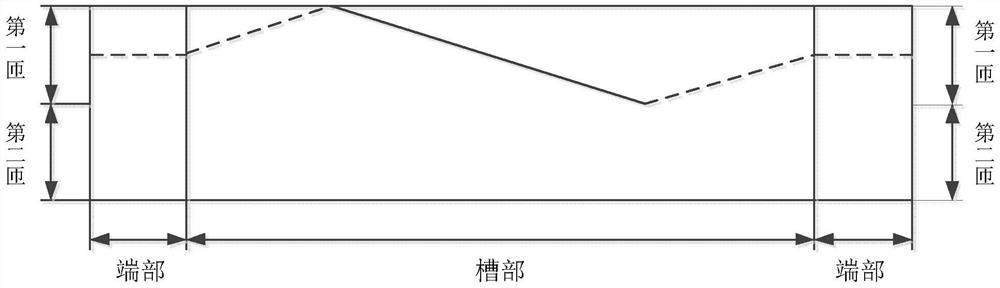

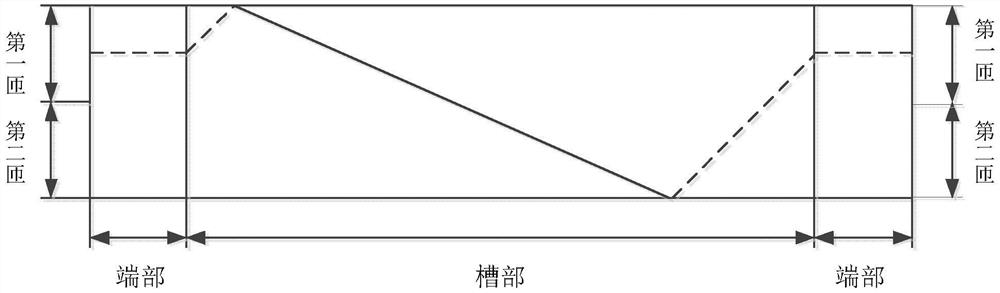

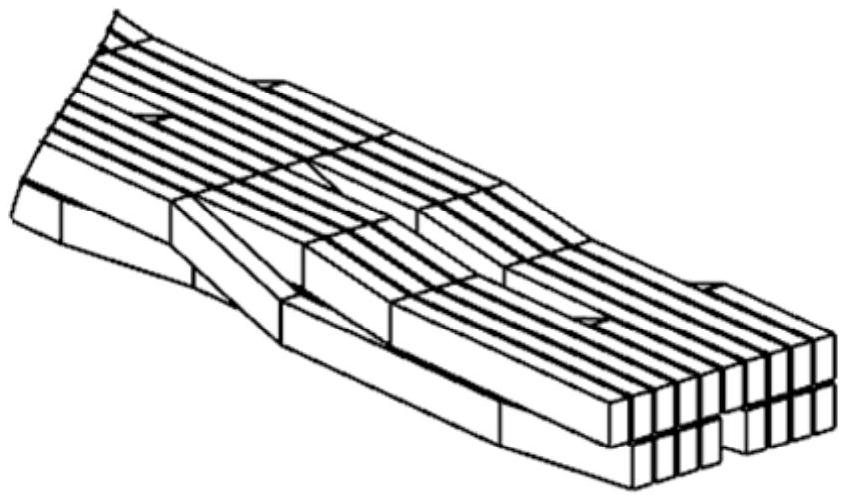

[0028] Specific implementation mode one: refer to figure 2 , 4 , 6, 7 and 9 specifically illustrate this embodiment, a method for transpositioning a stator bar of a permanent magnet synchronous motor with a forming transposition winding described in this embodiment, wherein the permanent magnet synchronous motor includes M layers of windings, and each layer of windings includes N turn coil, the strands in the coil are all flat wire structures. In this embodiment, N=2, and all strands in the 2-turn coil are regarded as a whole, that is, a group. The strands are arranged in 2 rows with 9 and 10 strands respectively, so that only one strand vacancy occurs in the two half-turn coils. Therefore, during the transposition, the 19 strands are transposed together by interweaving 360° between turns. The two coils overlap in the radial space of the slot, and each strand passes through the entire inner space during the transposition process. .

[0029] Specifically:

[0030] The str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com