A kind of microreactor, parallel high-efficiency microreactor and its application

A micro-reactor, reaction tube technology, applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc. Small and other problems, to achieve the effect of improving the mixing reaction efficiency, sufficient reaction, and improving the contact interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

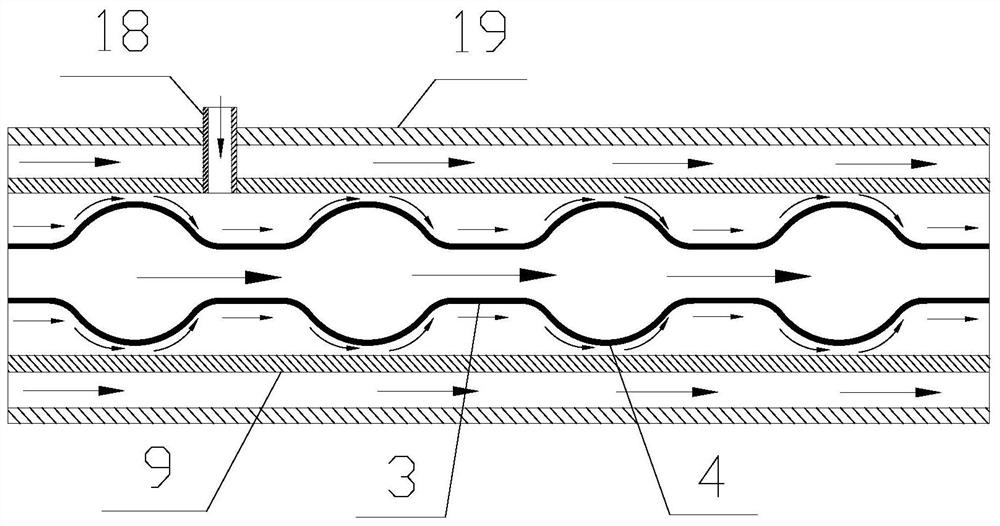

[0029] This embodiment discloses a microreactor, such as figure 1 As shown, it includes an outer tube 19, a reaction tube 9 and an inner tube 3 that are set in sequence from the outside to the inside, wherein the inner tube 3 has Karman vortex street generating parts 4 arranged at intervals along its length direction, and the mixing tube 18 passes through the outer tube 3. The tube 19 is communicated with the reaction tube 9; and the position where the mixing tube 18 is connected to the reaction tube 9 is located between the two Karman vortex street generation parts 4, and is close to the previous Karman vortex street generation part 4; the material A flows through the reaction tube 9 and the space between the inner pipe 3, the material B enters the space between the reaction pipe 9 and the inner pipe 3 through the mixing pipe 18, and is mixed with the material A. The working principle and advantages of the present invention are that: the material A flows through the space bet...

Embodiment 2

[0033] This embodiment discloses a microreactor, such as Image 6 As shown, the reaction tube 9 is a microporous membrane tube, and the microporous membrane tube is formed with tubular microporous portions 20 communicating with the inner space of the reaction tube 9 at intervals along its length direction. Between the generation parts 4, the material A flows between the reaction tube 9 and the inner tube 3, the material B flows between the outer tube 19 and the reaction tube 9, and the material B enters the reaction tube 9 through the tubular microporous part 20 and is connected with the reaction tube 9. The materials A forming the Karman vortex street phenomenon are mixed, the cooling medium A flows through the inside of the inner tube 3 , and the cooling medium B flows through the outside of the outer tube 19 . The advantage of this embodiment is that: the tubular microporous portion 20 plays a dispersing role, which further strengthens the mixing; the material B enters in t...

Embodiment 3

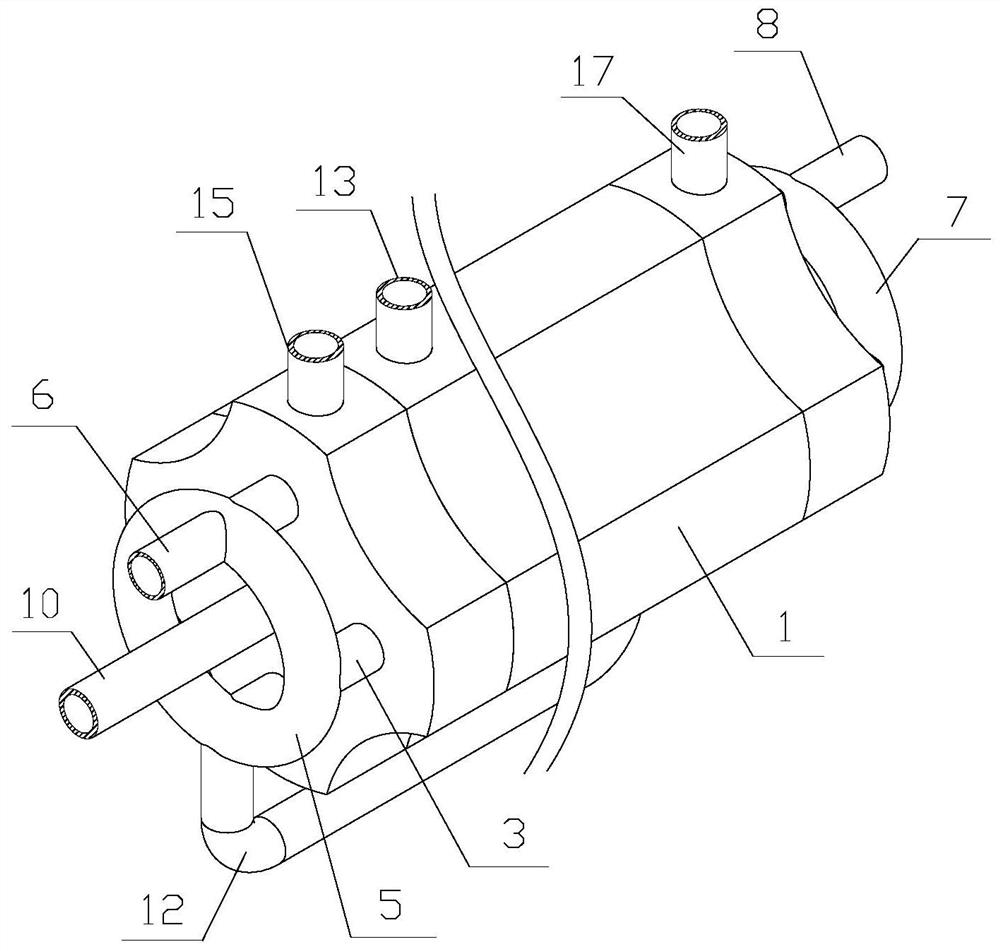

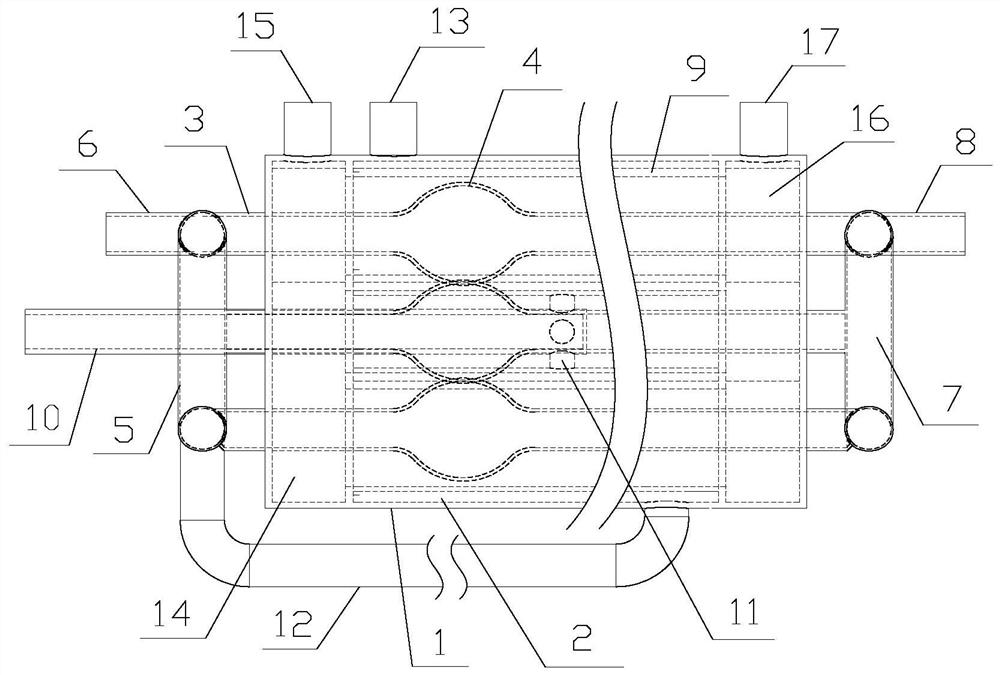

[0036] This embodiment discloses a parallel high-efficiency microreactor, such as Figure 2-5 As shown, it includes a plurality of inner tubes 3 and a plurality of reaction tubes 9 respectively sleeved outside the plurality of inner tubes 3 . Among them, a plurality of reaction tubes 9 are built in the reactor shell 1 , the cooling medium flows through the inner tubes 3 and the reactor shell 1 respectively, and the material A enters each of the first material tubes 10 through the plurality of branch pipes 11 In the space between the reaction tubes 9 and the corresponding inner tubes 3 , the material B enters the space between the reaction tubes 9 and the corresponding inner tubes 3 through the second material tube 15 . The working principle and advantages of the present invention are: the present invention is a parallel micro-reactor formed based on the above-mentioned micro-reactor, and the difference lies in that the outer tube 19 of the above-mentioned micro-reactor is replac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com