Method and device for continuously synthesizing tetrahydrophthalic anhydride

A technology for the generation of tetrahydrophthalic anhydride, applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, etc., can solve low conversion rate, poor product quality, reaction Long time and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

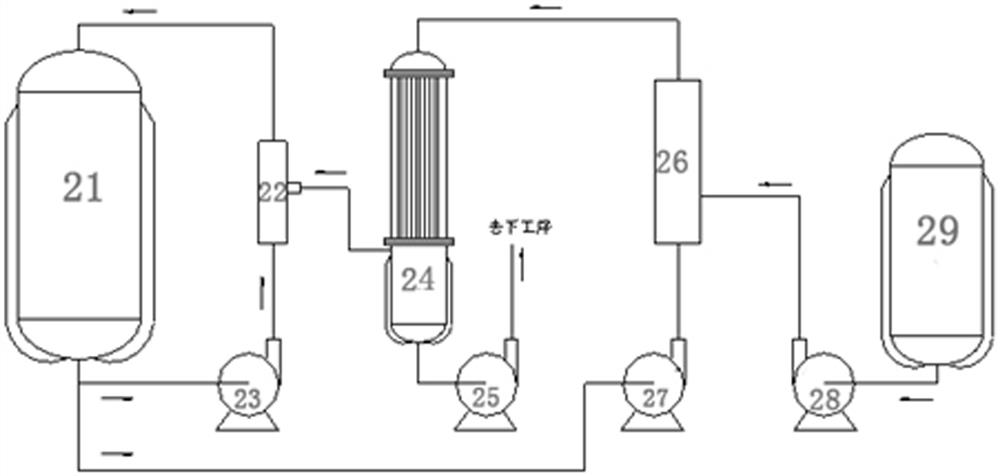

[0044] The butadiene in the butadiene material tank 29 enters the first-stage tubular microemulsion reactor 26 through the butadiene delivery pump 28; the maleic anhydride in the maleic anhydride material tank 1 enters through the delivery pump 27 In the first-stage tubular microemulsion reactor 26, butadiene and maleic anhydride react in the first-stage tubular microemulsion reactor 26; the reaction temperature is 60-150°C, and the pressure is 0.1-1MPa;

[0045] After the reaction is completed, the reaction product enters the flash tank 24 to remove excess butadiene and solvent, the pressure is 5-100kpa, and the product tetrahydrophthalic anhydride enters the product storage tank; the removed butadiene enters the jet mixer 22 in gas phase (Second-stage absorption reactor), maleic anhydride enters the jet mixer 22 through the circulation pump 23 to react with butadiene to absorb butadiene, and the reaction temperature is 60-150°C; maleic anhydride absorbs butadiene The mixed s...

Embodiment 2

[0048] Process flow condition is the same as embodiment 1.

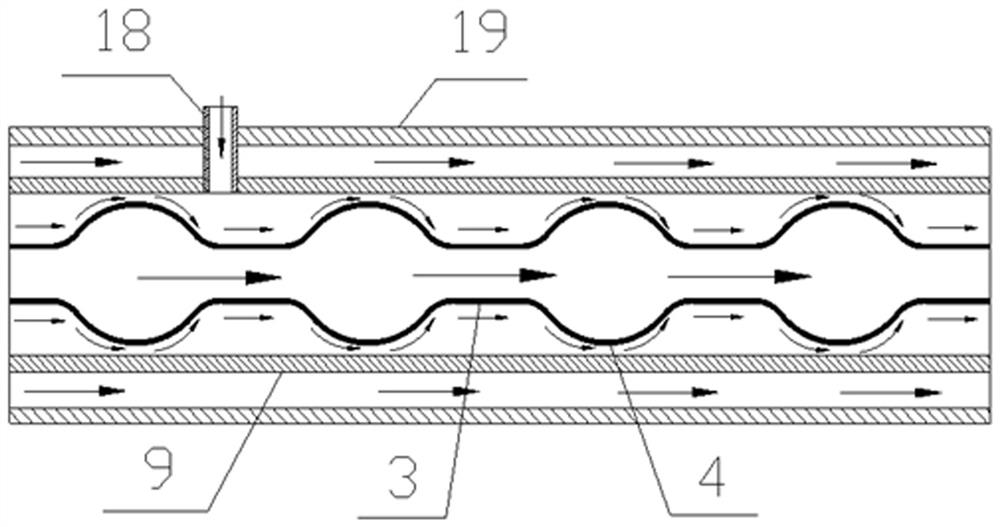

[0049] The first-stage tubular microemulsion reactor such as figure 2 As shown, it includes an outer tube 19, a reaction tube 9 and an inner tube 3 that are sequentially set from the outside to the inside, wherein the inner tube 3 has Karman vortex generation parts 4 that are arranged at intervals along its length direction, and the mixing tube 18 passes through the outer tube. Pipe 19 is also communicated with reaction tube 9; and the position that mixing tube 18 is connected with reaction tube 9 is positioned between two Karman vortex street generating parts 4, and near the former Karman vortex street generating part 4 places; Material maleic anhydride Flowing through the space between the reaction tube 9 and the inner tube 3, the material butadiene enters the space between the reaction tube 9 and the inner tube 3 through the mixing tube 18, and mixes and reacts with the maleic anhydride. The working principle an...

Embodiment 3

[0052] Process conditions and other structures are the same as in Example 2.

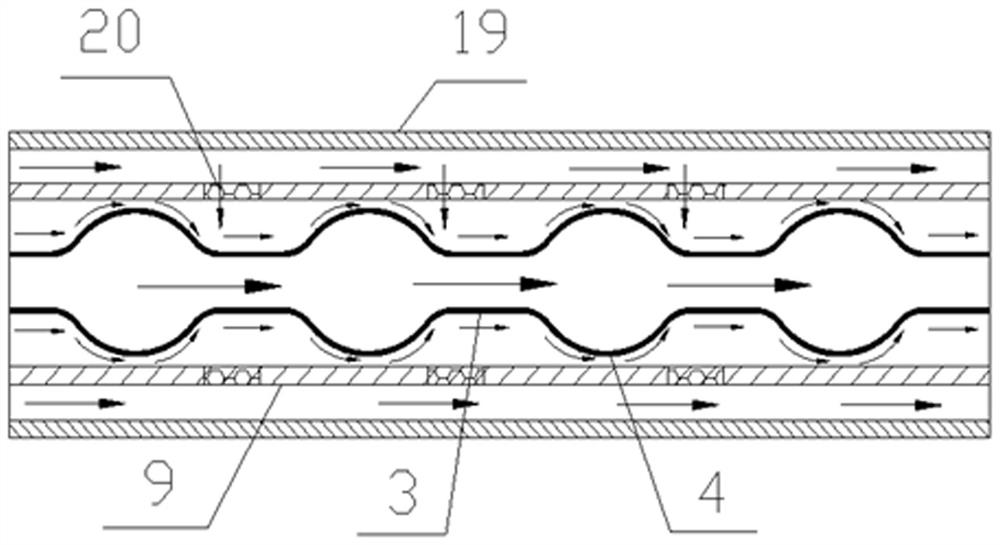

[0053] This embodiment discloses another tubular microemulsion reactor, such as image 3 As shown, the reaction tube 9 is a microporous membrane tube, and the microporous membrane tube is configured with tubular micropores 20 communicated with the internal space of the reaction tube 9 at intervals along its length direction. Between the street generation part 4, maleic anhydride flows between the reaction tube 9 and the inner tube 3, butadiene flows between the outer tube 19 and the reaction tube 9, and butadiene enters the reaction tube through the tubular micropore part 20. The inside of the tube 9 is mixed with maleic anhydride which forms the Karman vortex street phenomenon, the heat exchange medium A flows through the inside of the inner tube 3 , and the heat exchange medium B flows through the outside of the outer tube 19 . The advantage of this embodiment is that: the tubular microporous par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com