Medicine crushing, mixing and canning equipment for integrated traditional and western medicine department

A technology of mixing packing and medicinal materials, applied in the direction of grain processing, etc., can solve the problems of reducing the efficiency of crushing medicinal materials, high labor intensity, and long consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

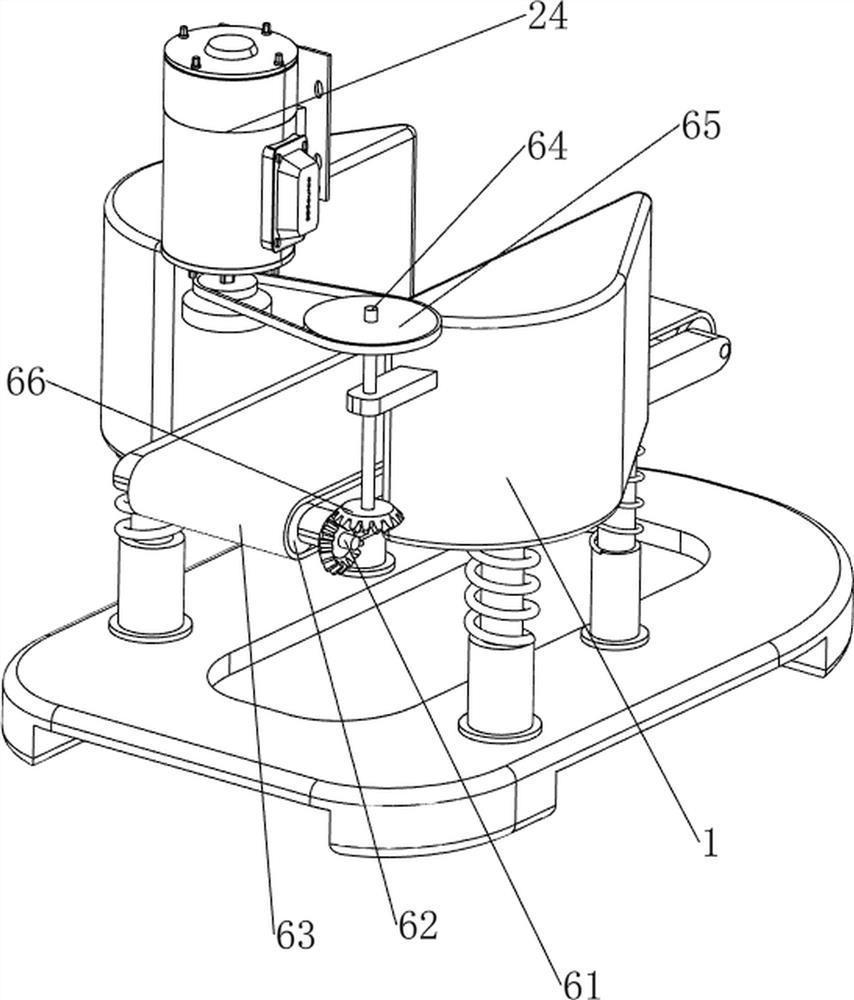

[0056] A kind of crushing and mixing canning equipment for traditional Chinese and Western medicine medicinal materials, such as figure 1 As shown, it includes a support frame 1, a stirring mechanism 2 and a crushing mechanism 3. The stirring mechanism 2 is connected to the support frame 1, and the crushing mechanism 3 is installed on the top of the stirring mechanism 2. The stirring mechanism 2 cooperates with the crushing mechanism 3.

[0057] First, workers need to put an appropriate amount of medicinal materials into the crushing mechanism 3, workers need to place the medicine tank at the bottom of the mixing mechanism 2, and then workers need to start the stirring mechanism 2 to rotate, the rotation of the stirring mechanism 2 will drive the crushing mechanism 3 to rotate, and then the medicinal materials are crushed , the medicine powder will fall into the mixing mechanism 2, and the mixing mechanism 2 will stir and mix the medicine powder, and the mixed medicine powder w...

Embodiment 2

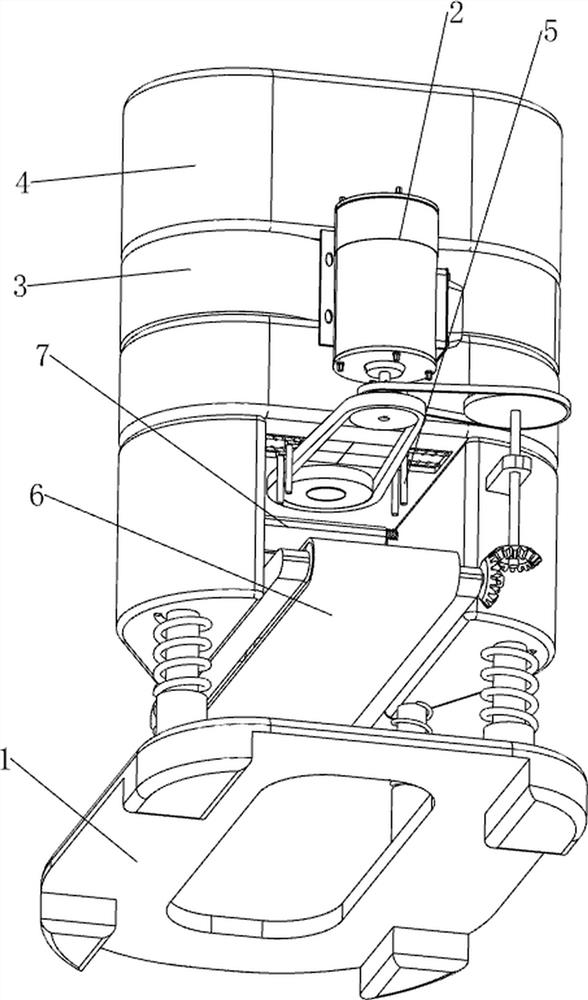

[0059] In a preferred embodiment of the present invention, as figure 2 As shown, the stirring mechanism 2 includes a stirring frame 21, a first rotating shaft 22, a stirring block 23, a motor 24 and a first transmission assembly 25, and a stirring frame 21 is connected between the top of the support frame 1, and the inner wall of the stirring frame 21 is rotated in the middle. There is a first rotating shaft 22, a stirring block 23 is arranged on the lower side of the first rotating shaft 22, a motor 24 is installed on the front side of the outer wall of the stirring frame 21, and a first transmission is connected between the output shaft of the motor 24 and the lower side of the first rotating shaft 22. Assembly 25, the first transmission assembly 25 is made up of two first pulleys and the first belt, one first pulley is connected on the lower side of the first rotating shaft 22, and the other first pulley is connected on the output shaft of the motor 24, and the belt is woun...

Embodiment 3

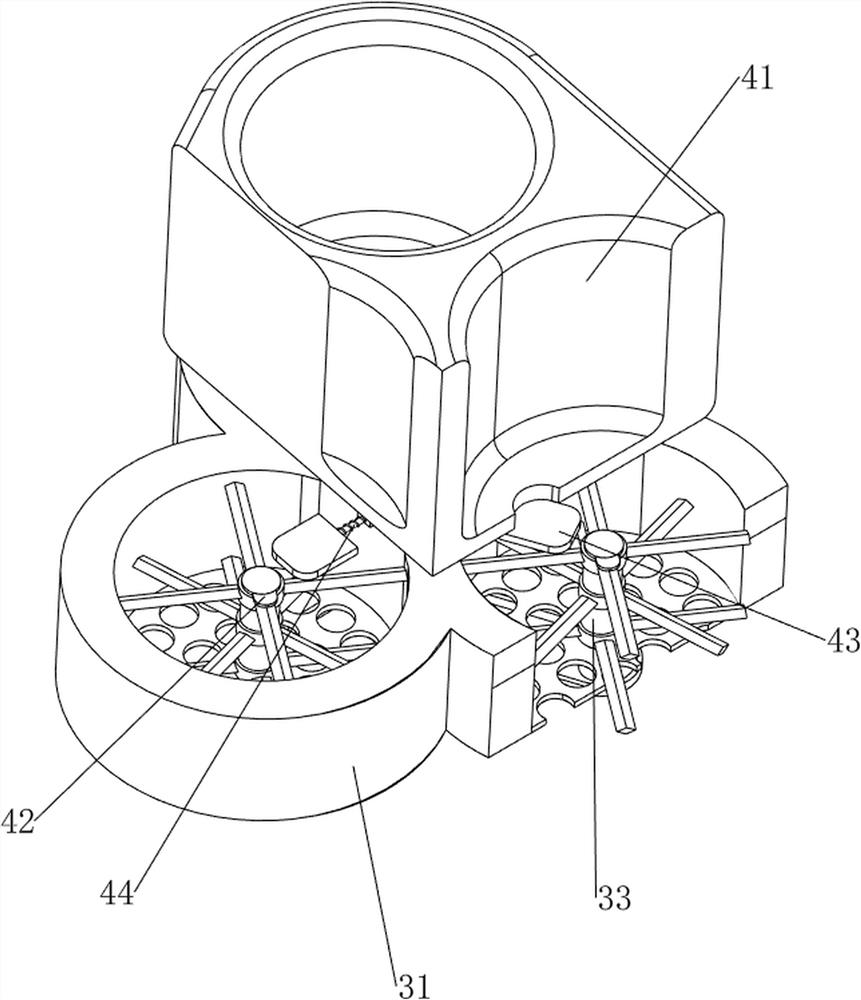

[0062] In a preferred embodiment of the present invention, as Figure 1-Figure 7 As shown, the crushing mechanism 3 includes a crushing frame 31, a filter plate 32, a second rotating shaft 33, a blade 34 and a second transmission assembly 35, the top of the stirring frame 21 is connected with a crushing frame 31, and the inner wall of the crushing frame 31 is uniformly provided with a filter plate 32 , the number of filter plates 32 is three, the three filter plates 32 are all rotatably provided with a second rotating shaft 33, the number of the second rotating shaft 33 is three, and the three second rotating shafts 33 are all provided with blades 34, the blades 34 The number is nine, the upper side of the first rotating shaft 22 and the lower side of the three second rotating shafts 33 are connected with the second transmission assembly 35, the number of the second transmission assembly 35 is three, and the second transmission assembly 35 consists of two The second pulley and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com