Tubular beam composite radius bending forming device

A bending forming and radius technology, applied in the field of pipe beam compound radius bending forming devices, can solve the problems of increasing equipment control costs, failing to achieve the accuracy of one-time forming using a mold, complex servo control of rollers, and achieving less disassembly and assembly workload. , The effect of reducing mold cost and stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

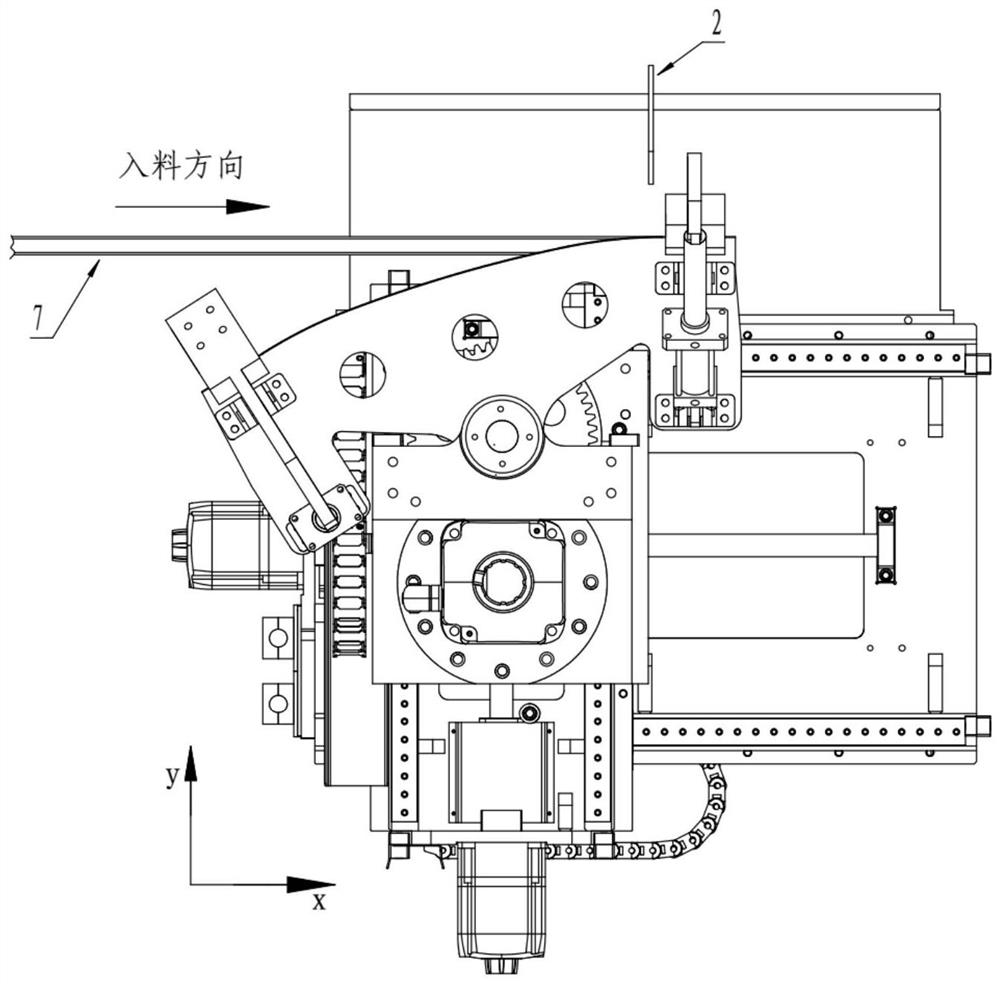

[0020] The device of the present invention is installed at the end of the rolling production line, and adopts a profiling die to perform bending and forming processing of compound radius on the straight pipe beam workpiece formed by rolling. Composite radius pipe beam refers to pipe fittings in which there are two or more arc sections with different radii in the elongation direction of the pipe beam workpiece. Such as Figure 5 In the shown embodiment, the pipe beam workpiece 7 has a curved portion 7-1 composed of three arc segments with different radii, and the two ends of the curved portion are respectively straight segments 7-2.

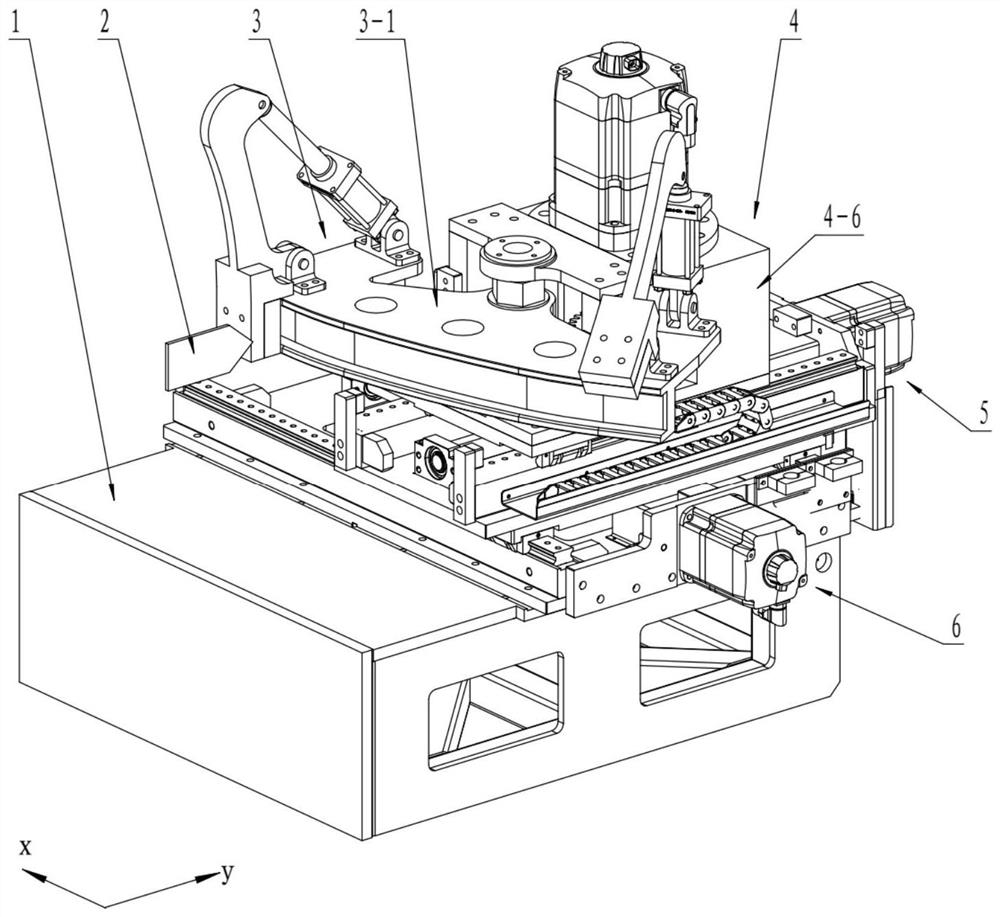

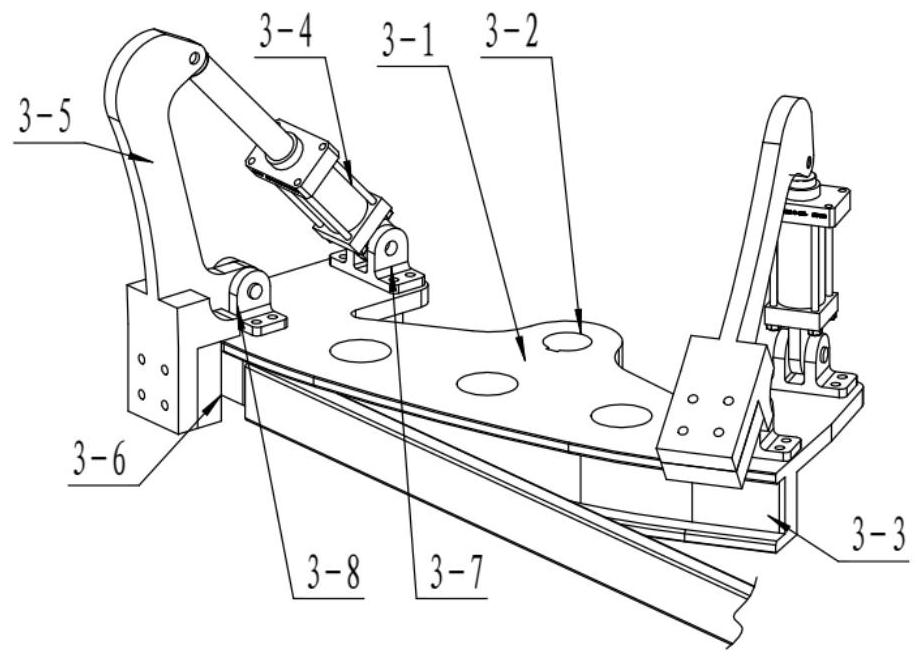

[0021] see figure 1 , image 3 , the present invention includes a base 1 , an X-direction moving mechanism 6 , a Y-direction moving mechanism 5 , an indexing mechanism 4 and a mold mechanism 3 . The base is the basic part of the device, and other mechanisms are all arranged on the base. The X-direction moving mechanism is directly installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com