A closed-mold molding process and device for composite materials

A composite material and molding process technology, applied in the field of composite material closed mold molding equipment, can solve the problems of inconvenient operation, inconvenient continuous operation, unfavorable processing output, etc., and achieve the effect of convenient installation and convenient closed mold molding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

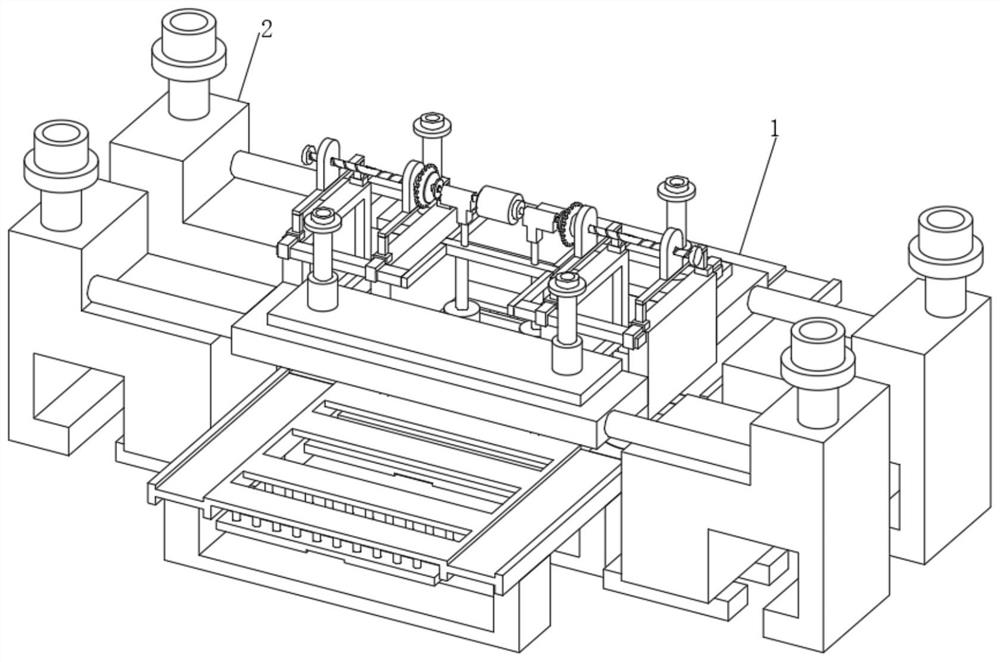

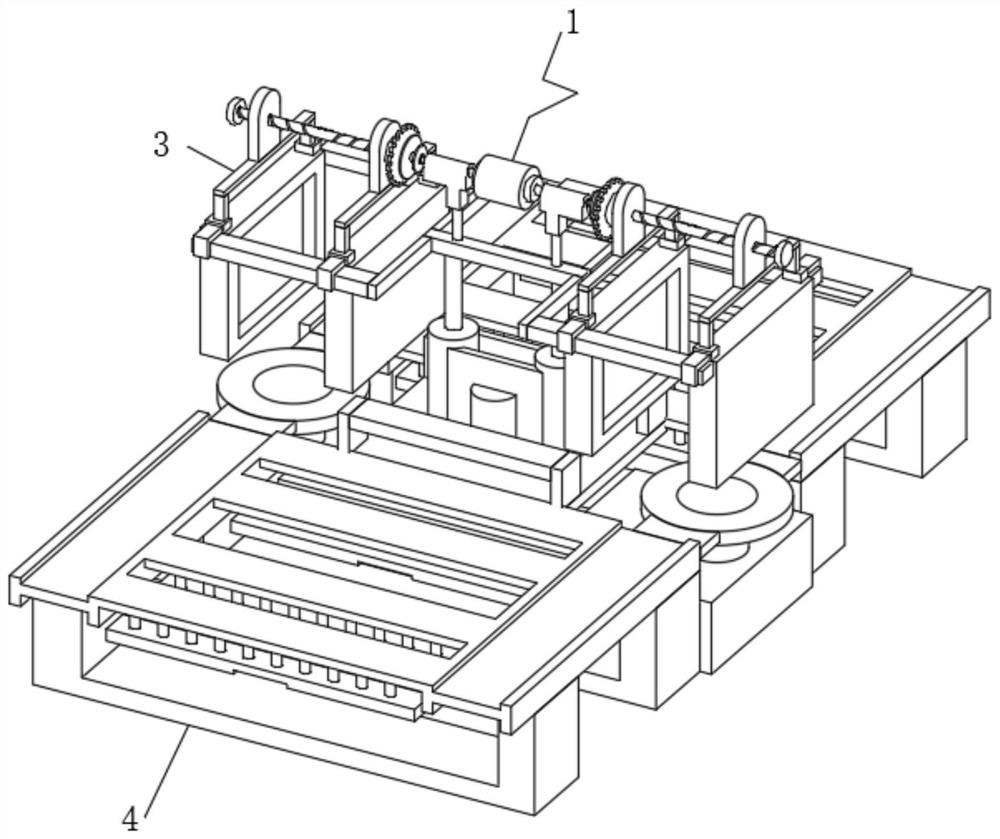

Image

Examples

Embodiment 1

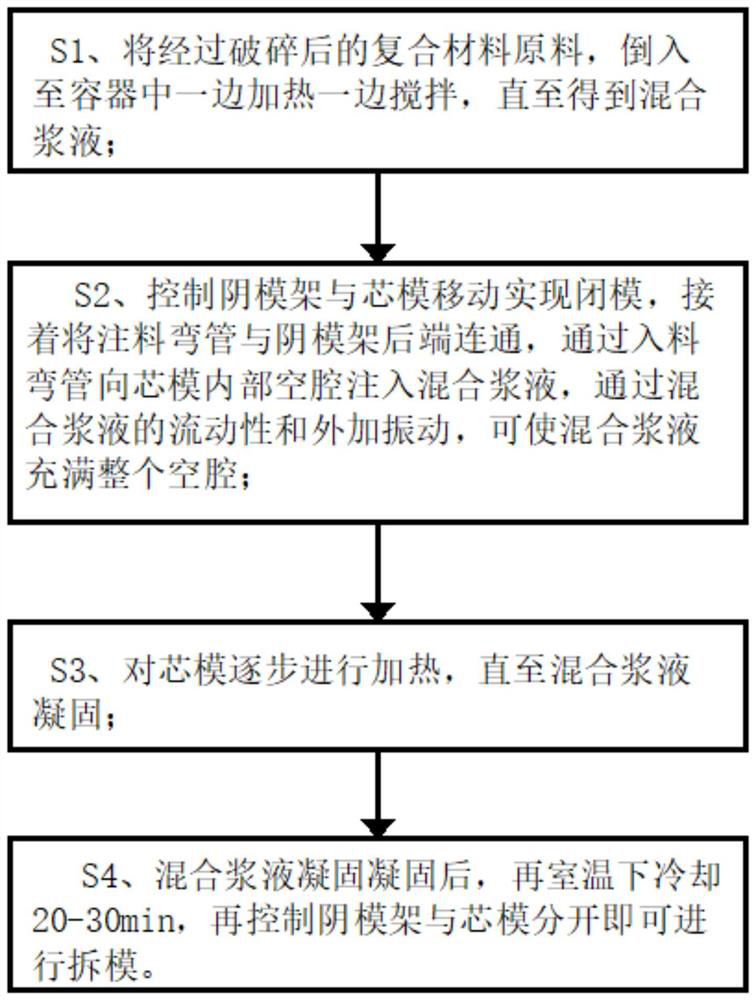

[0051] A composite closed molding processes used, such as figure 1 As shown, including the following steps:

[0052] Sl, the composite material after the raw material is crushed, poured into a container while heating with stirring, until a mixed slurry;

[0053] S2, the control of the female mold with the mold core mold closing achieve movement, then bend the hopper communicates with the rear end of the female mold, by feeding the mixed slurry injection elbow interior cavity to the mandrel, by mixing the slurry flowability and vibration is applied, the mixed slurry can fill the cavity;

[0054] S3, the core-mode gradually heated until the mixed slurry solidified.

[0055] S4, after mixing the slurry frozen frozen, and then cooled at room temperature for 30min, then the control of the female mold and the core mold can be carried out separately form removal.

[0056] Preferably, the step S1, the composite material comprising by weight parts: 80 parts of novolac epoxy resin, 6 parts ...

Embodiment 2

[0070] On the basis of Example 1, if Figure 11 , The mold closing apparatus 1 further includes a top cover 35, the pillar support plate 36, heater bar 37 and mounting bracket 38, the support plate 36 disposed upright in the buffer gantry side end position 33, the upper end position of the support column mounting plate 36 bracket 38 is fixedly connected to the upper end position of the mounting bracket and the top plate 35 of the sleeve 38 is fixedly connected to the heating rod 37 is electrically connected at a bottom position of the mounting bracket 38.

[0071] In use of this embodiment, the user, sets the top plate 35, and mounting bracket 38 helps to install a heating rod 37 of the heating rod 37 may be electrically connected to the outside through the heating rods 37 to achieve the mounting, the mounting bracket 38 and a bottom end plate 36 by a support pillar and the side end of the cushion frame 33 is fixedly connected to the tub, a supporting installation with each other, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com