Material supply equipment for carton printing machine

A technology for supplying equipment and printing machines, applied in object supply, thin material handling, pile separation, etc., can solve problems such as troublesome, non-material lifting functions, etc., and achieve the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

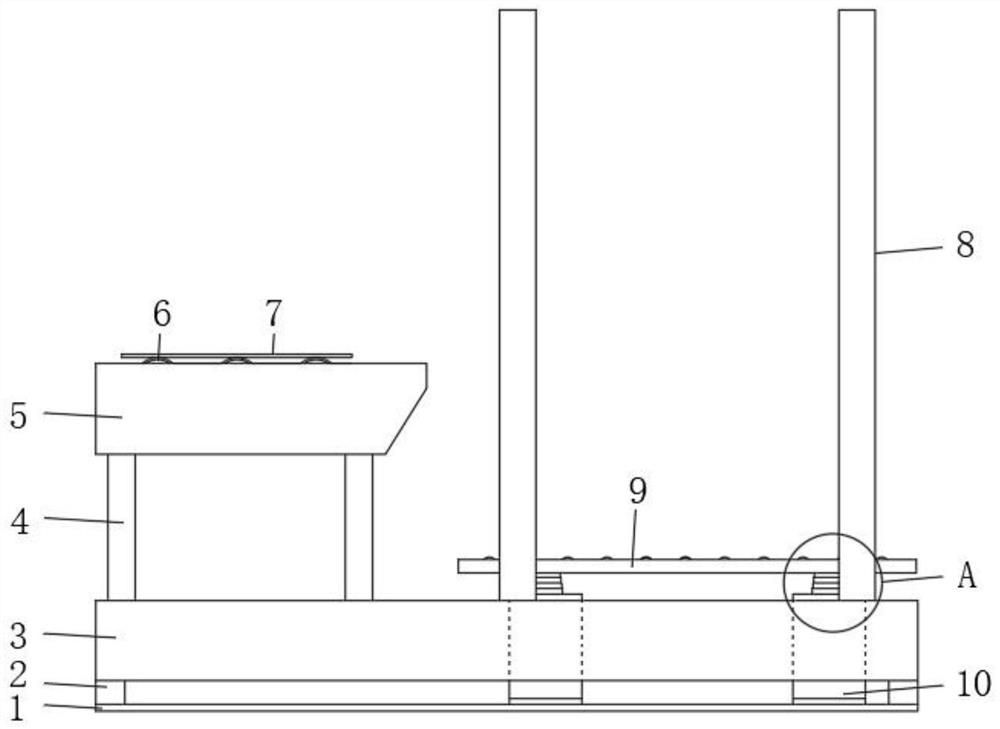

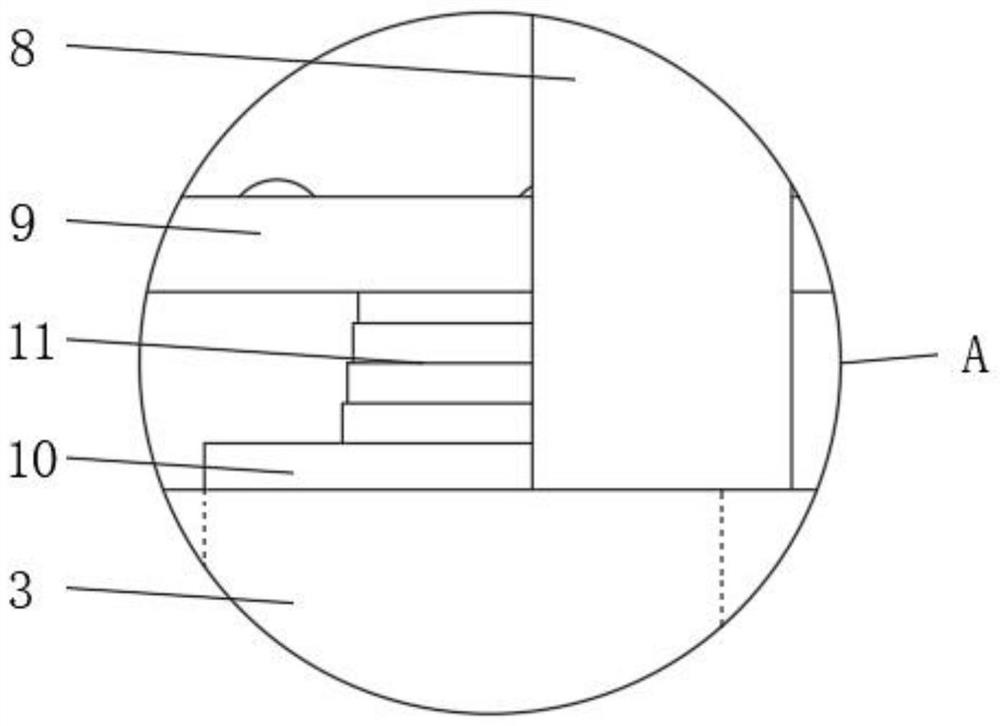

[0037] see Figure 1 to Figure 4, an embodiment provided by the present invention: a material supply device for a carton printing machine, including a bottom plate 1, a base 3, a chassis 5 and a flat plate 9, and the four corners of the lower surface of the base 3 are respectively welded with brackets 2, four The bottom ends of each bracket 2 are respectively welded to the four corners of the upper surface of the base plate 1, and four hydraulic cylinders 10 are embedded in a rectangular array on one side of the base 3, and the hydraulic cylinders 10 are connected to external hydraulic pumps, as is well known to those skilled in the art Yes, the provision of hydraulic pumps is commonplace, which belongs to conventional means or common knowledge, and will not be repeated here, and those skilled in the art can make arbitrary selections according to their needs or convenience. One side of the base 3 is provided in a rectangular array with four sockets matching the hydraulic cylin...

Embodiment 2

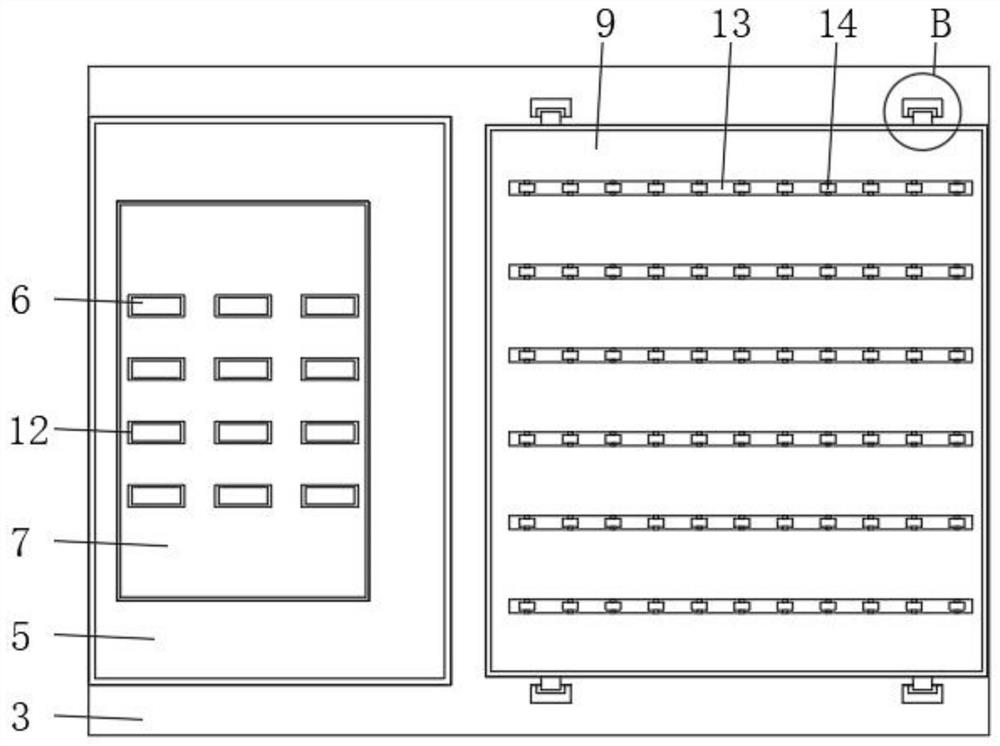

[0040] see figure 1 , image 3 , Figure 5 and Image 6 , an embodiment provided by the present invention: a material supply device for a carton printing machine, four pillars 4 are welded in a rectangular array on the other side of the upper surface of the base 3, and the top ends of the four pillars 4 are respectively connected to the chassis 5 The four corners of the lower surface are welded, and the top of the cabinet 5 is provided with a square hole 20, and the two sides of the top of the cabinet 5 at the square hole 20 are respectively fixed with a drive box 18 and a gear box 22, and the drive box 18 and the gear box 22 are rotated and installed with Transmission rod 19, the transmission wheel 6 is set on the transmission rod 19, two cylinders 17 are symmetrically fixed on the top of the cabinet 5, and the cylinders 17 are connected to the external air pump. Means or common knowledge will not be repeated here, and those skilled in the art can make arbitrary selections...

Embodiment 3

[0042] An embodiment provided by the present invention: a material supply device for a carton printing machine, the feeding process:

[0043] S1. Before feeding, the hydraulic cylinder 10 is started, the multi-stage hydraulic rod 11 is retracted to the lowest point, the flat plate 9 is lowered to the lowest point, and the cartons are stacked on the flat plate 9, and the bottom carton is in contact with the roller 14;

[0044] S2. After the carton is placed, start the hydraulic cylinder 10, the multi-stage hydraulic rod 11 rises to drive the flat plate 9 to move upward, and the flat plate 9 drives the carton to move upward. According to the height of the cartons stacked at the 5 places of the chassis, the height of the flat plate 9 is stacked at the 5 places of the chassis. The height of the cartons is the same;

[0045] S3. Push the cartons on the flat 9, and the cartons on the flat 9 move from the flat 9 to the top of the cartons stacked at the chassis 5 under the action of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com