A flapping-torsional coupled motion flapping aircraft

A flapping-wing aircraft and coupling motion technology, applied in the field of flapping-wing aircraft, can solve the problems of many driving moving parts, no lift, complex structure, etc., and achieve the effect of less driving moving parts, large effective lift and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

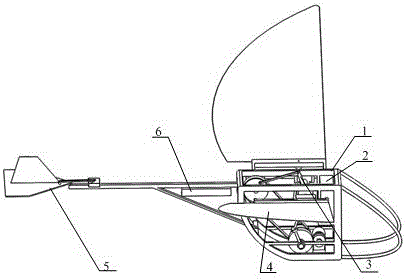

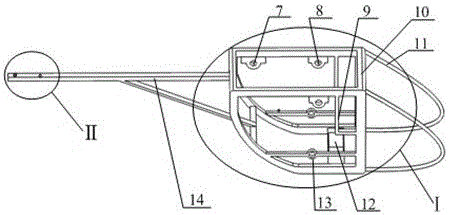

[0043] A flapping-wing coupled motion flapping-wing aircraft. Such asfigure 1 As shown, the flapping-wing aircraft is made up of a fuselage 1, a drive mechanism 3, two wings 4, an empennage mechanism 5 and a control system. Let the fuselage head be the front, the left side facing the fuselage head be the left, the front and rear directions be the vertical direction, and the left and right directions be the horizontal direction.

[0044] The fuselage 1 is formed by sequentially connecting the fuselage head 11 , the fuselage middle 10 and the fuselage tail 14 .

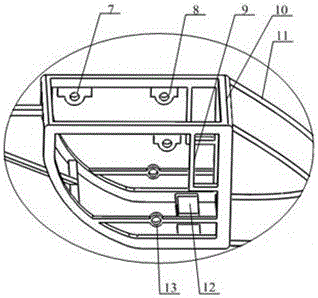

[0045] The structure of the middle part 10 of the fuselage is: the vertical frame on the left side and the vertical frame on the right side are connected into a box-shaped frame by four horizontal horizontal bars, and the vertical frames on both sides are arranged symmetrically. Longitudinal horizontal beams are arranged symmetrically near the bottom of the vertical frame, and first bearing blocks 13 are symmetrically ...

Embodiment 2

[0062] A flapping-wing coupled motion flapping-wing aircraft. Except following technical parameter, all the other are with embodiment 1:

[0063] The length of the lower horizontal bar in the longitudinal direction is 0.5 to 0.6 times that of the horizontal bar in the longitudinal direction, and the length of the rear vertical bar is 0.3 to 0.4 times that of the front vertical bar.

[0064] The fixed connection between the rear end of the longitudinal fixed rod and the middle of the longitudinal horizontal rod means that the angle between the longitudinal fixed rod and the longitudinal horizontal rod at the joint is 27-30°.

[0065] The width of the closed end of the concave member 34 is 0.7-0.8 times the width of the base of the airfoil 32 .

[0066] Compared with the prior art, this specific embodiment has the following positive effects:

[0067] This specific embodiment is made up of fuselage 1, driving mechanism 3, two wings 4, empennage mechanism 5 and control system, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com