Water purifier

A technology for water purifiers and water inlets, which is applied in water/sewage treatment, chemical instruments and methods, water/sewage treatment equipment, etc., and can solve the problem of clogging of ultrafiltration membrane filter elements, reduction of purified water outlet flow, and clogging of membrane filaments, etc. problem, to achieve the effect of prolonging the service life, improving the cleaning efficiency and preventing the clogging of the filter element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0037] First specific embodiment

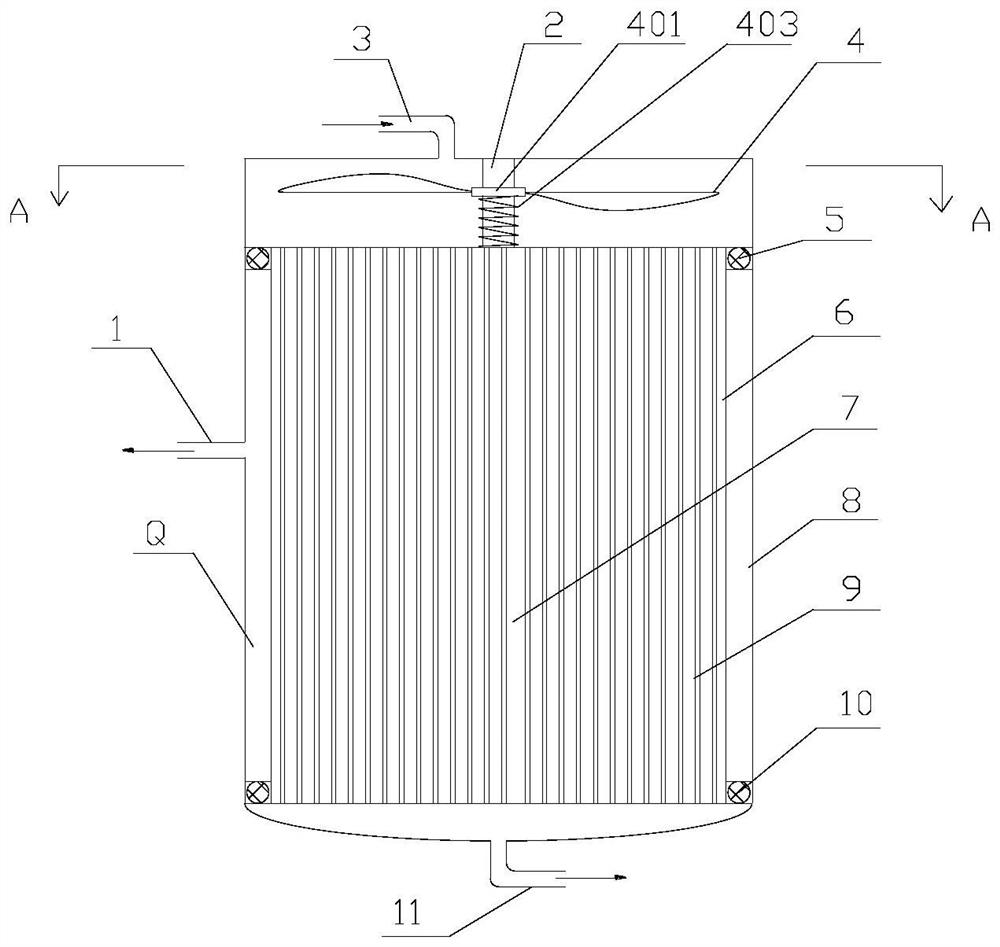

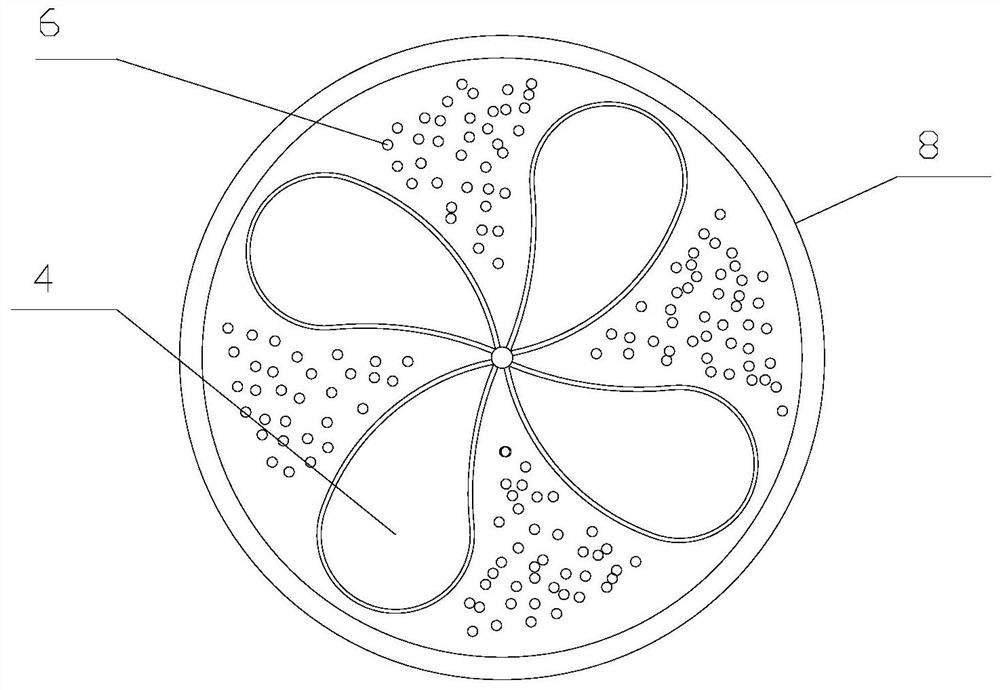

[0038] See Figure 1 to 5 The water purifier provided by the first embodiment of the present invention includes a housing 8, a filter cartridge 6, and a rotating impeller 4. among them:

[0039] The filter element 6 is mounted in the outer casing 8, which is assembled by a plurality of film sides for filtration to produce purification water;

[0040] The upper cover of the outer casing 8 is provided with an inlet port 3 and a fixed column 2, and the fixed column 2 is located inside the upper cover and is adapted to it;

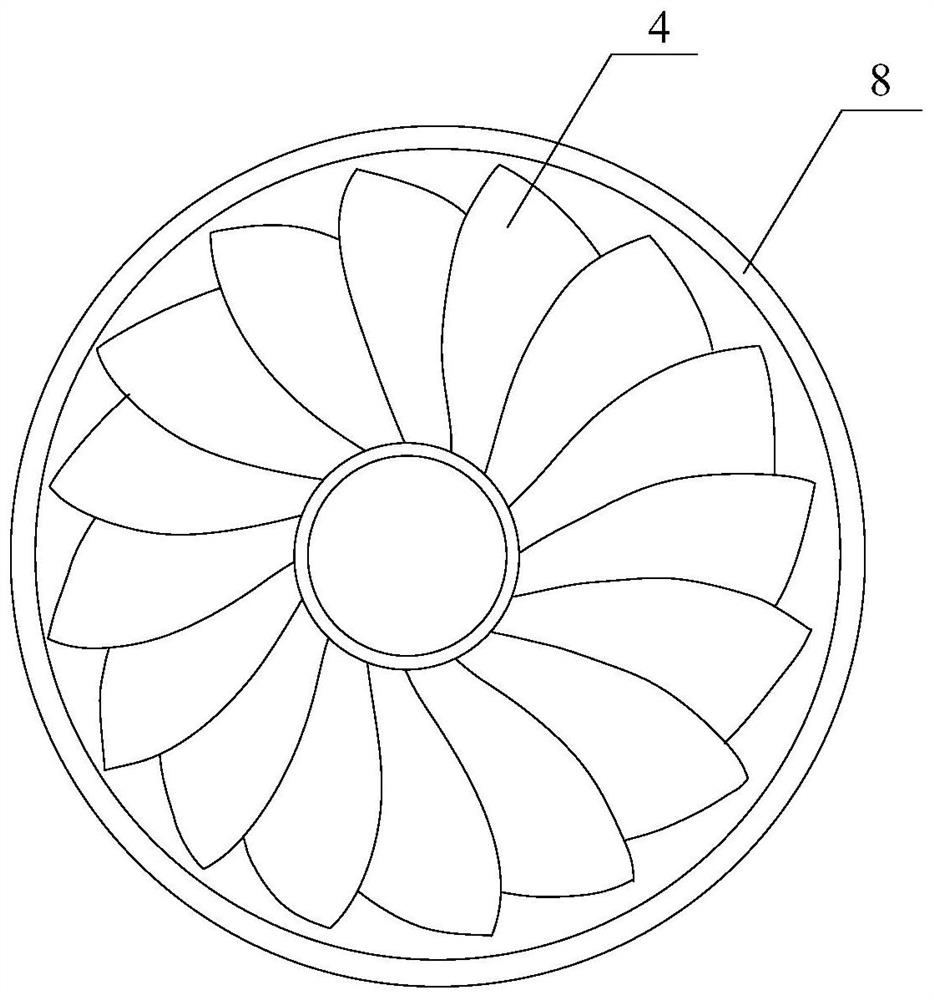

[0041] The rotary impeller 4 is rotatably mounted on the fixed column 2, and is located between the inlet port 3 and the inlet end of the filter element 6, and the blades in the rotating impeller 4 are inclined blades.

[0042] Among them, the inclined blade refers to a certain angle at a certain angle of the central plane of the blade and the vertical plane perpendicular to the central axis of the fixed column 2, which is general...

Example

[0063] Second embodiment

[0064] The difference between the water purifier provided in the first embodiment of the present invention and the first embodiment of the present invention is only that the elastic member 403 and the connecting sleeve 402 are disposed above the bearing 401, please refer to Figure 6 One end of the elastic member 403 is adhered to the inner ring of the bearing 401, and the other end and the shoulder solids of the fixed column 2.

Example

[0065] Third Specific Example

[0066] The difference between the water purifier according to the third embodiment of the present invention and the water purifier of the first embodiment of the present invention is only that the elastic member 403 and the connecting shaft sleeve 402 are disposed above the bearing 401, please refer to Figure 7 At one end of the elastic member 403 and the inner ring of the bearing 401, the other end and the inner side of the outer casing 8.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap