Vibrating ash cleaner for exhaust-heating boiler

A technology for cleaning ash device and waste heat boiler, which is used in the removal of solid residue, lighting and heating equipment, combustion product treatment, etc. Stable and reliable equipment operation, good cleaning ability, reliable and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

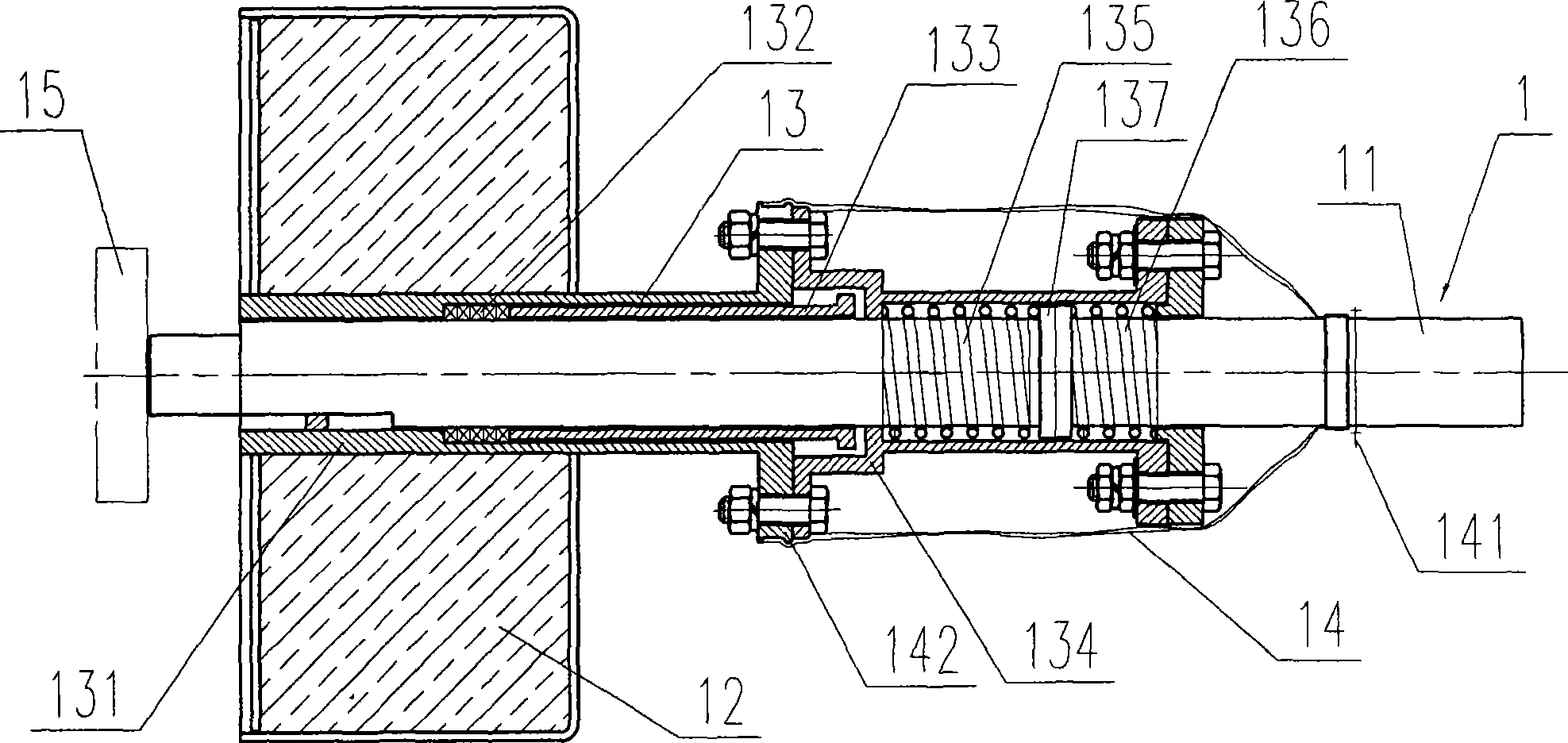

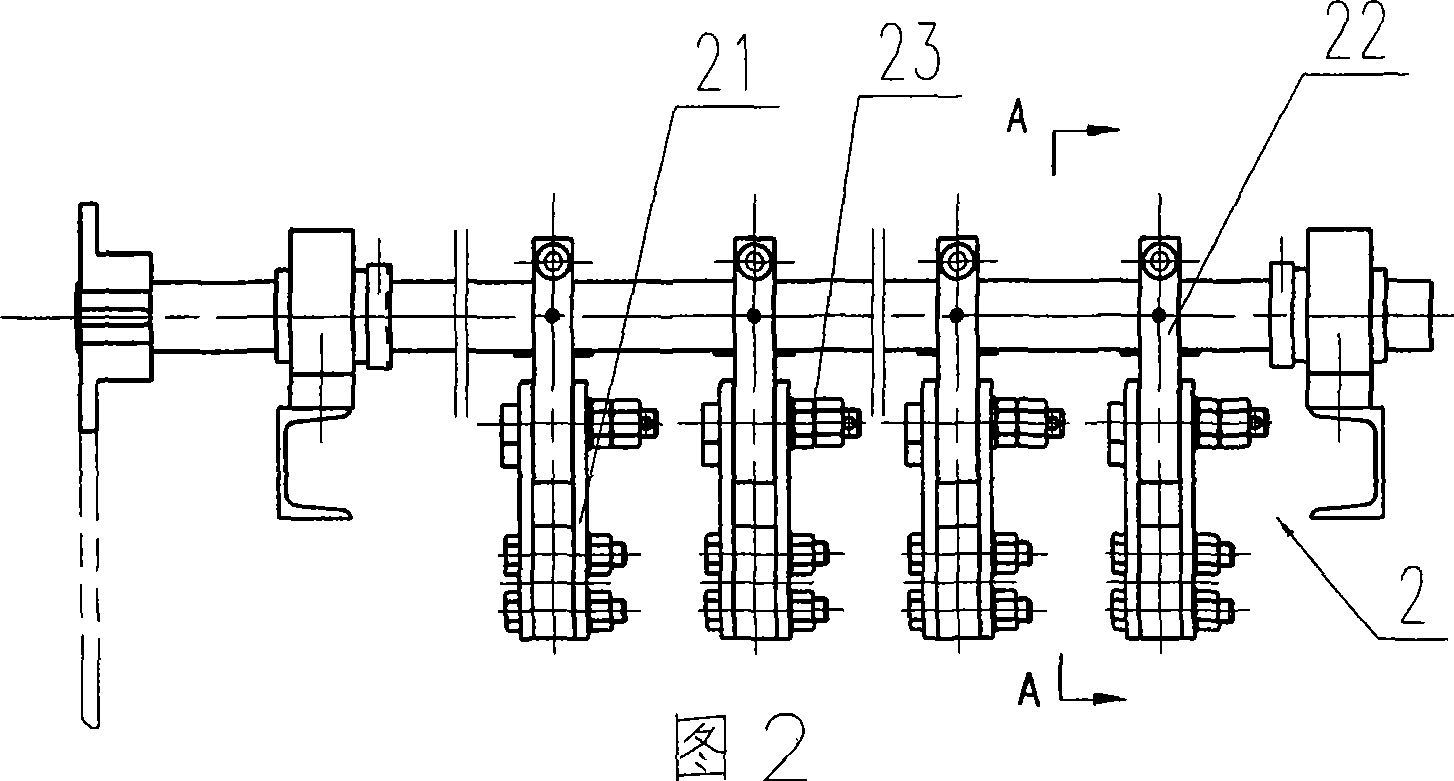

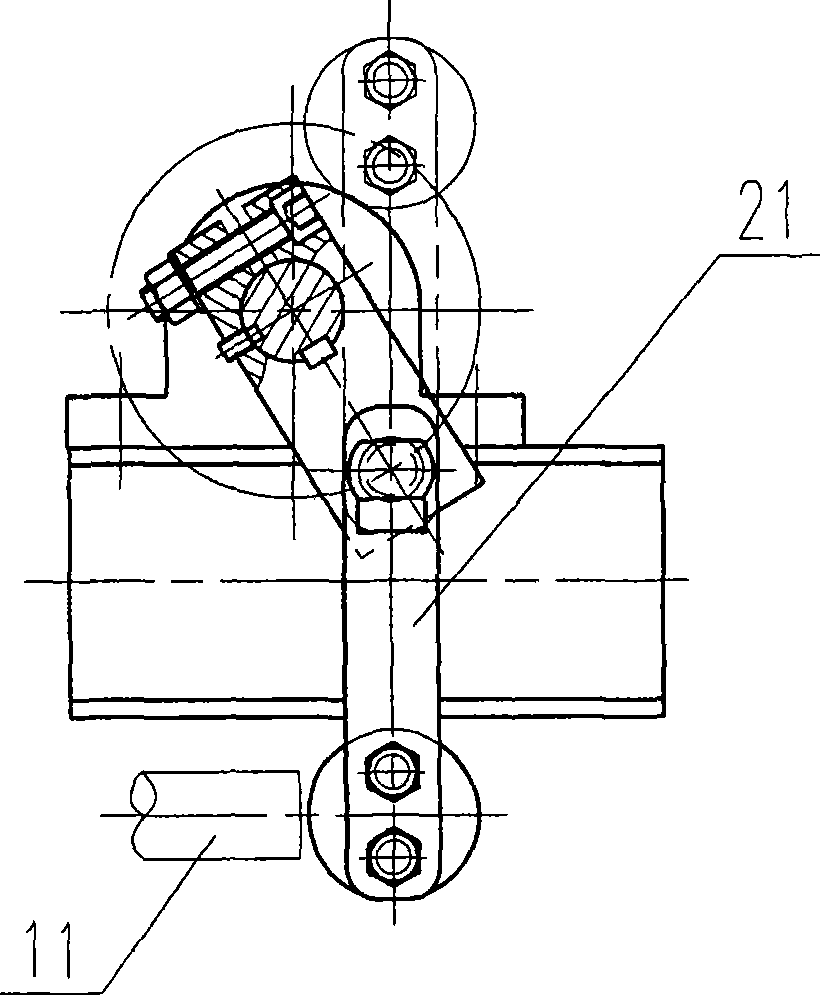

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings: the present invention mainly consists of a rapping rod mechanism 1, a rapping hammer mechanism 2 and a motor transmission mechanism. figure 1 As shown, the rapping rod mechanism 1 includes a rapping rod 11 with one end in contact with the rapping surface. The rapping rod 11 passes through the wall of the heat preservation box 12 and is provided with a sealing device 13 . The sealing device 13 includes a guide sleeve 131 fixed on the wall of the insulation box 12, the rapping rod 11 passes through the guide sleeve 131, and an oil-soaked asbestos disc is arranged between the guide sleeve 131 and the rapping rod 11 Root 132.

[0012] The outside between the guide sleeve 131 and the rapping rod 11 is also sleeved with a pressure sleeve 133, and the outside of the pressure sleeve 133 is provided with a left and right two sleeves placed on the rapping rod 11 by the spring sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com