Partition wall board for fabricated building and partition wall structure of partition wall board

A technology for partition boards and buildings, which is applied in building components, building structures, buildings, etc., can solve the problems of insufficient connection strength, poor stability of partition walls, and insufficient strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

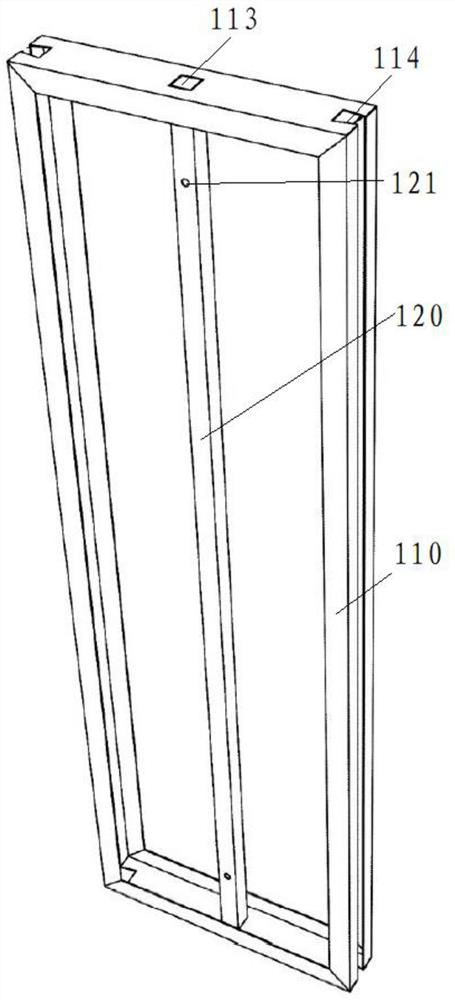

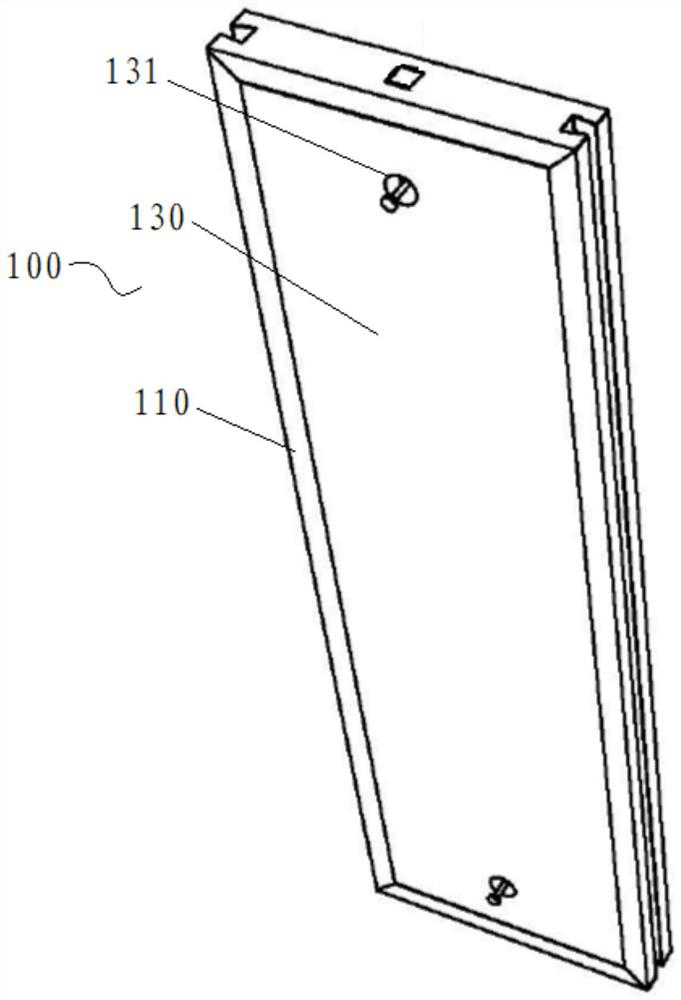

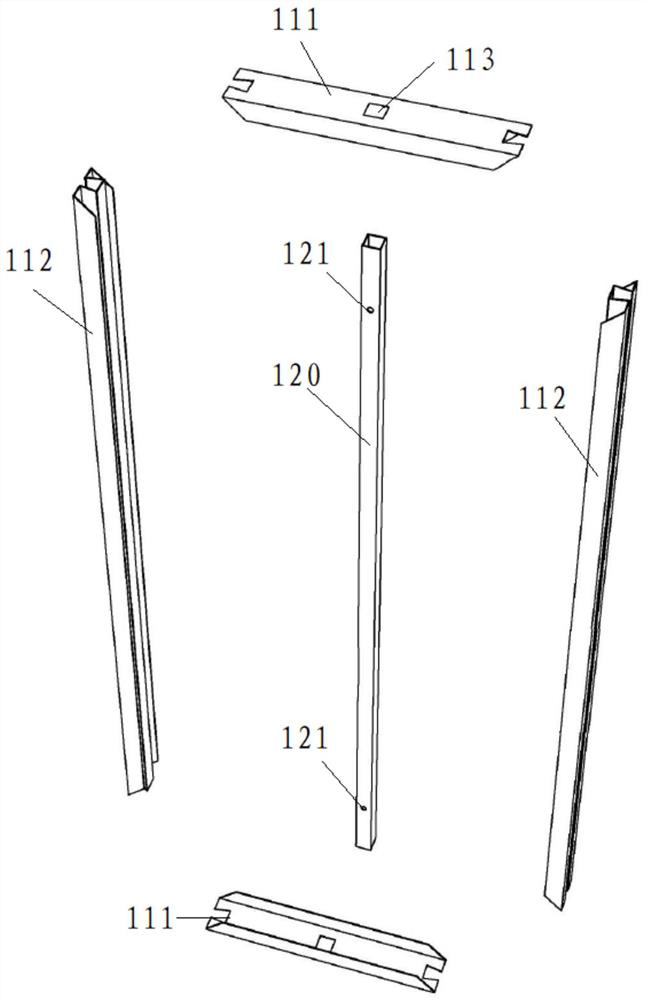

[0051] figure 1 , 2 They are respectively a structural schematic diagram of an outer frame of a prefabricated building partition wall panel and a structural schematic diagram of a partition wall panel provided by an embodiment of the present application, such as figure 1 , 2 As shown, the partition wall panel 100 includes a wall panel core 130 , an outer frame 110 and a reinforcement flute 120 .

[0052] In the embodiment of the present application, when defining the partition wall body with the partition wall panel 100, the direction parallel to the height direction of the partition wall body is the height direction (ie, the up and down direction) of the partition wall panel 100, and the direction parallel to the partition wall body width The direction parallel to the direction is the width direction of the partition wall panel 100 , and the direction parallel to the thickness direction of the partition wall body is the thickness direction of the partition wall panel 100 . ...

Embodiment 2

[0063] Based on the same inventive concept as the partition wall panel for a prefabricated building in the first embodiment, the embodiment of the present application also provides a partition wall structure for a prefabricated building.

[0064] Figure 6-9 They are the structural representations of a prefabricated building partition wall structure provided by an embodiment of the present application Figure 1 , structural representation Figure II , exploded view and top view, such as Figure 6-9 As shown, the partition wall structure includes the partition wall panel 100 , horizontal connectors 200 and vertical connectors.

[0065] The partition panels 100 are arranged in alignment, specifically: the ports of the reinforcement corrugations 120 of the two partition panels 100 adjacent in the height direction are aligned and penetrated, and the two partition panels 100 adjacent in the width direction The connecting groove 114 is aligned. The horizontal connecting piece 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com