Large-scale experimental device and method for magnetic signal detection in solute transport under saturated medium

An experimental device and solute transport technology, applied in the direction of material magnetic variables, can solve the problems of preferential flow, difficult to simulate the structural characteristics of deep aquifer reservoirs, lack of large-scale experimental devices, etc., to achieve the effect of enhancing magnetic signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

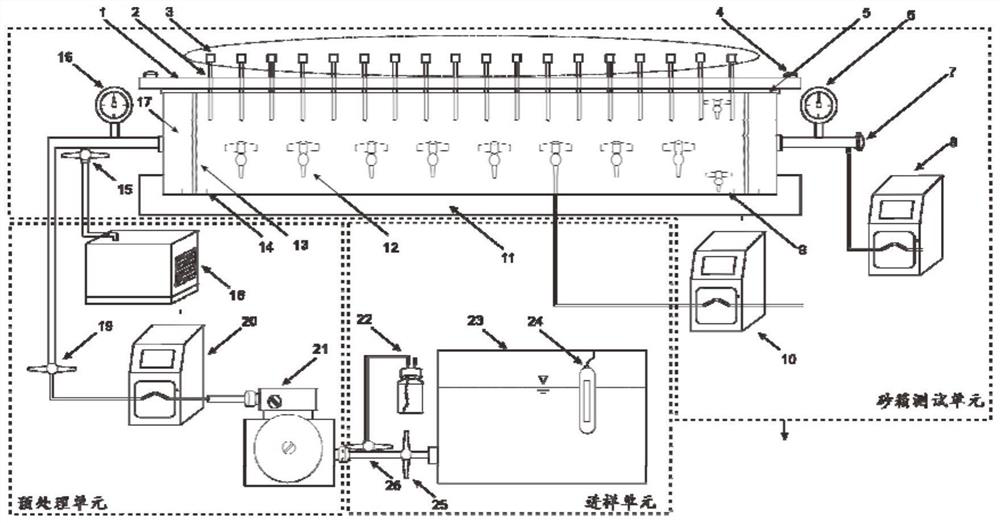

[0084] Such as figure 1 Shown: the large-scale experimental device for magnetic signal detection in solute migration under saturated medium of the present invention, the device includes: vacuum pump 18, water inlet valve 19, first port peristaltic pump 20, booster pump 21, sample bottle 22, water tank 23. Heating device 24, water tank valve 25, sample bottle valve 26;

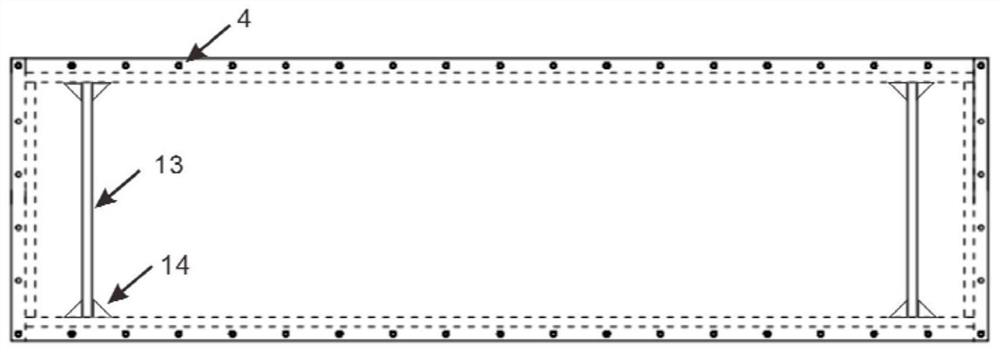

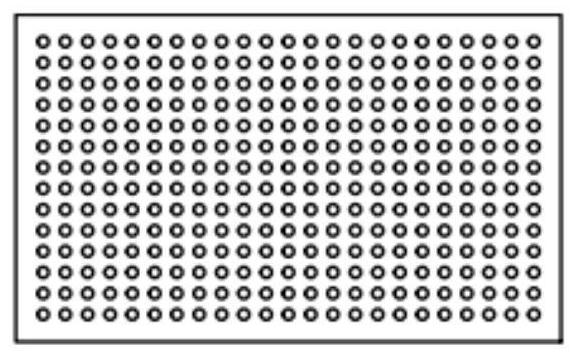

[0085] The sand box includes: sand box top plate 1, sand box top plate drilling 2, magnetic probe 3, top plate screw 4, rubber pad 5, water outlet pressure gauge 6, water valve and sampling point 7, second peristaltic pump 8, sand box Side wall vertical water valve and sampling point 9, side wall sampling point peristaltic pump 10, sand box bottom reinforcement device 11, sand box side wall horizontal water valve and sampling point 12, perforated partition and stainless steel mesh 13, perforated partition Plate reinforcement device 14, vacuum pump water valve 15, water inlet pressure gauge 16, compartment 17. ...

Embodiment 2

[0088] Embodiment 2, on the basis of Embodiment 1, turn on the switch of the heating device 24, maintain the water temperature at 25°C (above the indoor temperature), slowly inject the fluid, and turn on the booster pump 21 when the water tank pressure cannot guarantee the height of the water inlet head. The first peristaltic pump 20 slowly injects fluid (the flow rate should be lower than <20ml / s), and gradually removes the air inside the sand box. After the medium in the sand box is saturated, open the water outlet valve 7 of the sand box system and the second peristaltic pump 8, And adjust the peristaltic pump 8 and the peristaltic pump 20 to ensure a stable flow rate (the flow rate should be within the controllable range of the peristaltic pump).

Embodiment 3

[0089] Embodiment three, fill the sand layer inside the sand layer, and tighten the top plate screw 4, and the water inlet water valve 15 and the water outlet sampling place water valve 8, the water valve 12 and the water valve 9 at the sand box side wall sampling place, use Plug the plug to close the hole 2 on the top plate, turn on the vacuum pump 18, observe the change of the pressure gauge 16 at the water inlet, turn off the vacuum pump before reaching the maximum pressure bearing capacity of the sand box (≈ the maximum pressure measurement water head under saturated medium), turn on the sand box, and repeat the above steps After instructing the vacuum pump that the sand layer does not appear sunken, turn on the switch of the heating device 24, maintain the water temperature at 25°C (assumed value), slowly inject the fluid, and when the pressure of the water tank cannot guarantee the height of the water inlet head, turn on the booster pump 21, the first Peristaltic pump 20,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com