Optical component driving mechanism, imaging device, and electronic apparatus

A technology of optical components and driving mechanisms, applied in optical components, optics, installation, etc., can solve problems such as increased cost, inconsistent shaking of double shrapnel, unfavorable development trend of mobile phone camera motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

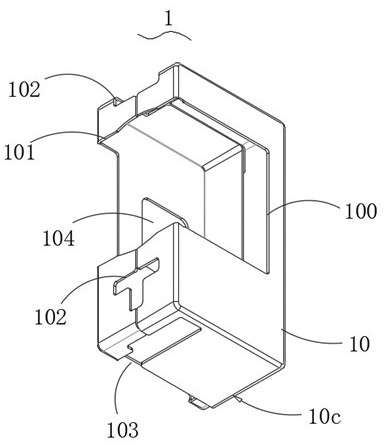

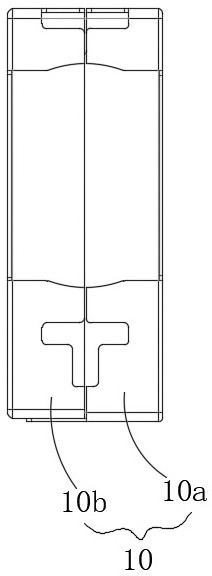

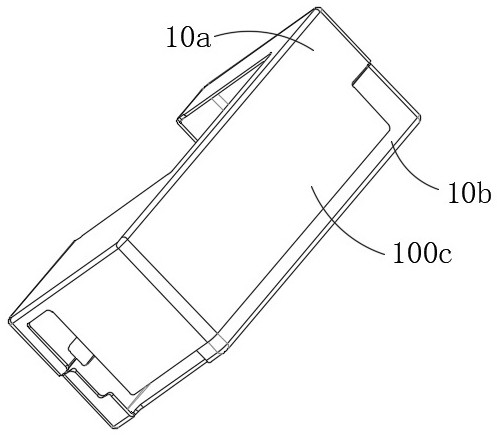

[0069] Such as Figure 4 with Figure 9 As shown, the present invention provides an optical member driving mechanism L, an arrow in the figure represents the light and the light-raised direction, and the prism L0 is positioned in a plurality of direction position adjustments by the optical component drive mechanism to meet the use requirements.

[0070] Specifically, the optical member drive mechanism 1 of the present embodiment includes a casing 1 and a base 2, and a circuit board 3 is fixed to the base 2, and the base 2 has a single carrier receiving space, and the single carrier 4 is mounted to a single carrier receiving by an elastic support mechanism. In the space, the present embodiment provides an electromagnetic drive mechanism, a Y-axis electromagnetic drive mechanism, and an inclined X-axis electromagnetic drive mechanism to drive the single carrier 4, and synergistic elastic support mechanism for correcting the offset of the refractive light of the optical component. .

...

Embodiment 2

[0211] On the basis of the above embodiment, such as Figure 17 As shown, the present invention also provides an image pickup apparatus having an optical member driving mechanism L, and a lens driving mechanism T, and a lens driving mechanism T at an optical member T, and a lens driving mechanism T, using an optical component drive mechanism. Change the optical path, and the lens drive mechanism T is synergistic, and high-precision ultra-clear camera operations can be achieved.

Embodiment 3

[0213] On the basis of the above embodiments, if Figure 18 As shown, the present invention also provides an electronic device, such as a mobile phone, an imaging device having a second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com