Induction heater for performing postweld heat treatment on small-diameter pipe welding head without cooling and manicuring method of induction heater

A post-weld heat treatment and induction heater technology, which is applied in the field of heat treatment, can solve problems such as heat treatment of welded joints of small-diameter pipes that are difficult to handle, and achieve the effects of reducing deformation, prolonging life, and improving overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

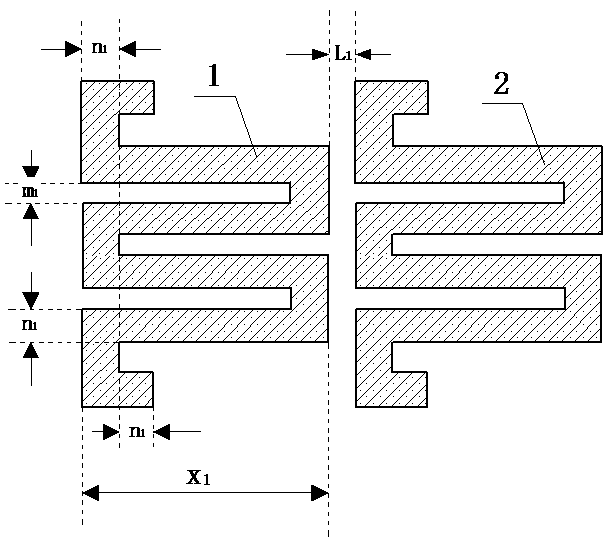

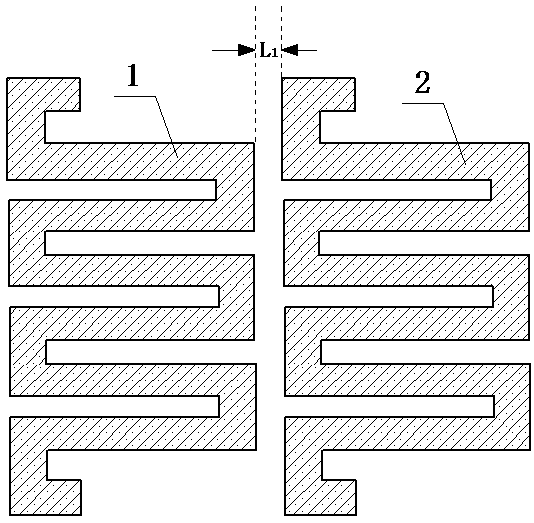

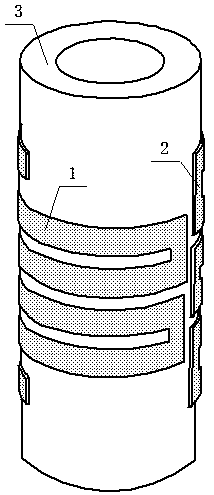

[0049] Such as figure 1 Shown: First process pure copper into the required shape and size according to the heat treatment requirements of φ45mm single tube, then recrystallize and anneal it to reduce the hardness, and then bend it into such image 3 If the semi-circular arc shape is shown and electroless plating is performed, the conductive layer 32 of the sensor is made. After bonding the inductor insulation layer 31 on the mold, place the inductor conductive layer 32, then bond the inductor insulation layer 33, and then dry to obtain two sheet-like serpentine veneer semicircular arc inductors. The two sheet-like snake-shaped veneer semi-circular arc inductors are combined mechanically, and the welding seam can be heated by passing an electric current.

Embodiment 2

[0051] Such as figure 2 Shown: First process pure copper into the required shape and size according to the heat treatment requirements of φ70mm single tube, then perform recrystallization annealing to reduce the hardness, and then bend it into such image 3 As shown in the continuous semi-circular arc shape, there is a natural transition between the arcs, and then electroless plating is performed to form the conductive layer 32 of the inductor. After bonding the inductor insulation layer 31 on the mold, place the inductor conductive layer 32, then bond the inductor insulation layer 33, and then dry to obtain two sheet-like serpentine veneer semicircular arc inductors. The two sheet-like snake-shaped veneer semi-circular arc inductors are combined mechanically, and the welding seam can be heated by passing an electric current.

[0052] The present invention uses a Cu chip with a certain thickness as the inductor, which greatly saves space and solves the problem of heat treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com