Small-diameter rack pipe after-welding heat treatment no-cooling induction heater and manufacturing method thereof

An induction heater and post-heat treatment technology, which is applied in the field of heat treatment, can solve problems such as difficult to handle, achieve the effects of prolonging life, reducing water-cooling circulation systems, and improving overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

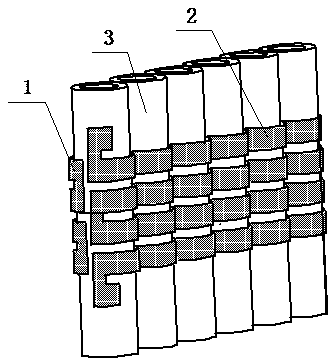

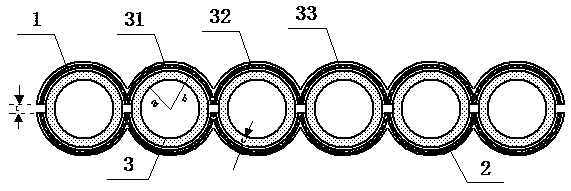

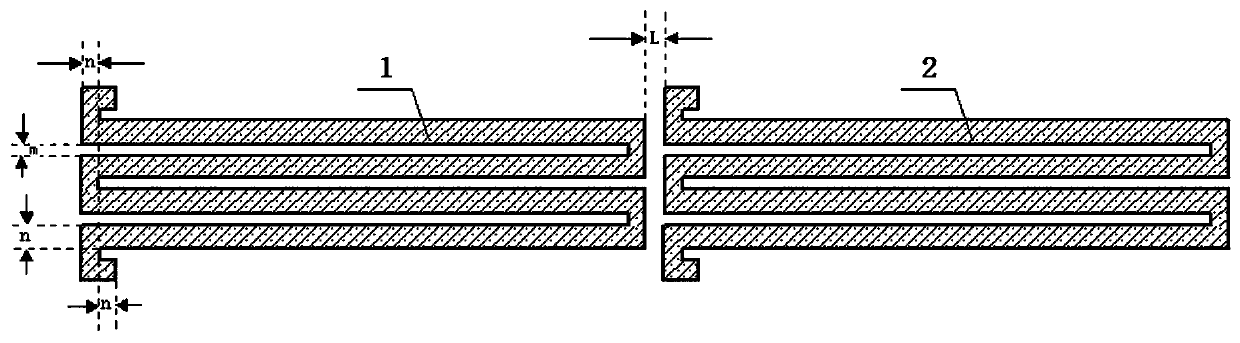

[0034] Example: see figure 1 , figure 2 and image 3, a non-cooling induction heater for post-weld heat treatment of small-diameter pipes, including small-diameter pipes 3, which are composed of several equal-diameter and small-diameter pipes, and small-diameter pipes are provided with conductive induction heaters at the outer wall welds of small-diameter pipes 3. The small-diameter pipe conductive sensor is a sheet-like serpentine veneer structure, which is divided into the left sheet-shaped small-diameter pipe conductive sensor 1 and the right sheet-shaped small-diameter pipe conductive sensor 2, and the left sheet-shaped small-diameter pipe conductive sensor 2. Both the sensor 1 and the conductive sensor 2 of the sheet-shaped small-diameter row tube on the right are composed of several fan-shaped ring structures. The number of fan-shaped ring structures is determined by the number of small-diameter tubes in the small-diameter tube row. The inner ring radius b of the fan r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com