Vertical winding device for flat wire

A flat wire and vertical winding technology, applied in the field of coil preparation equipment, can solve the problems of large space occupation and long length of vertical winding device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

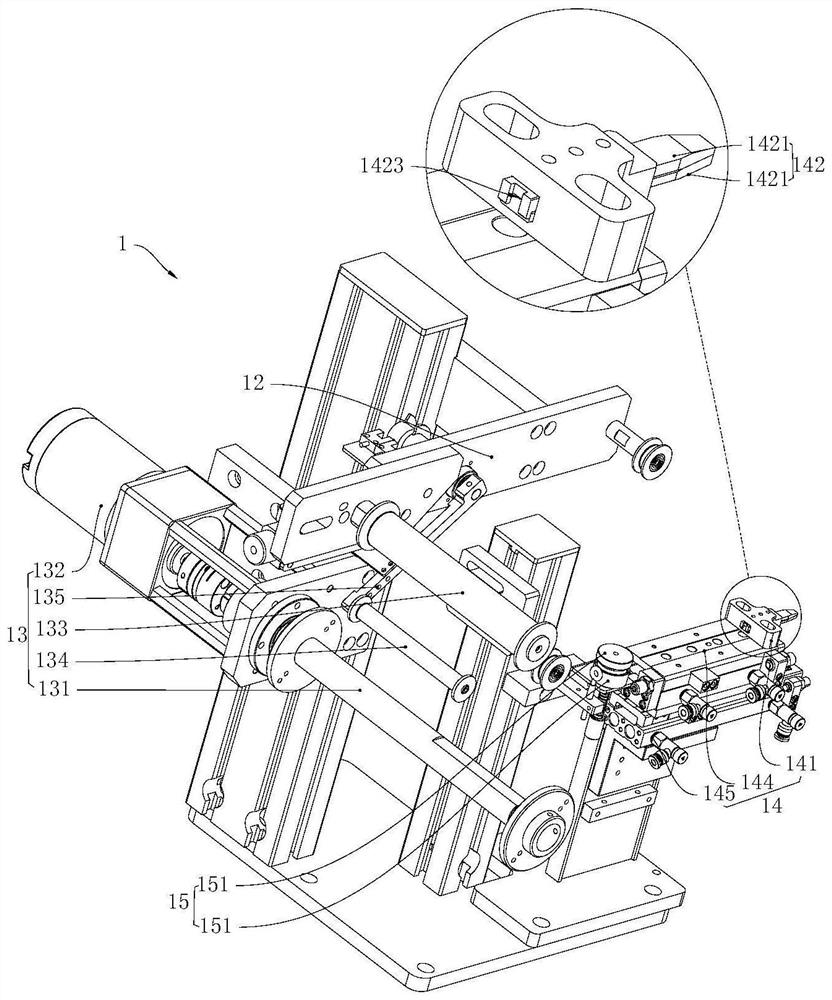

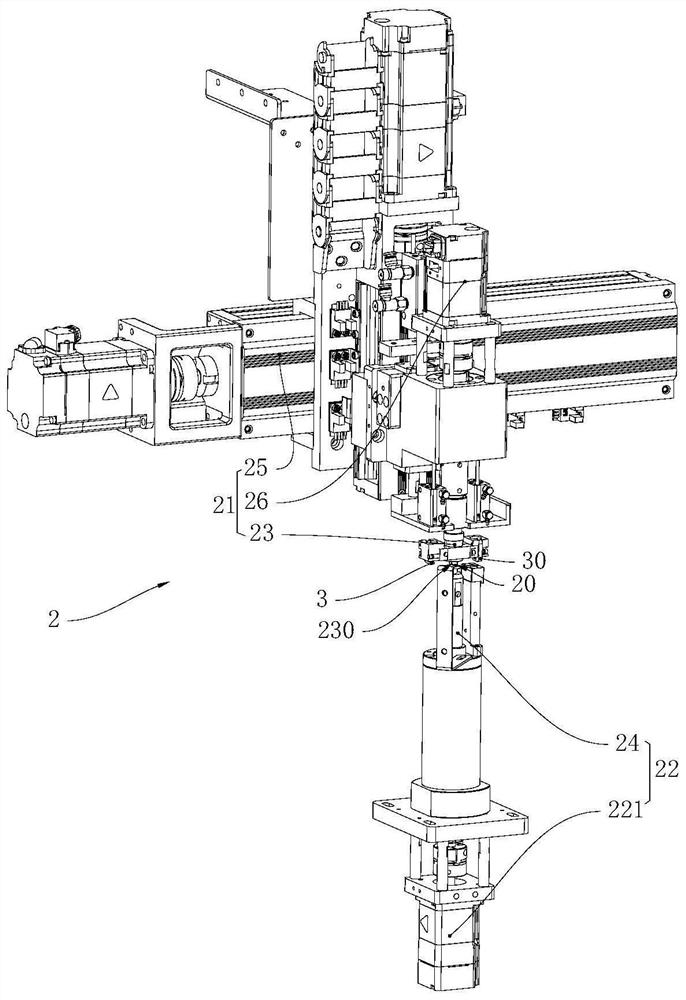

[0048] The flat wire vertical winding device of the present invention is applied to a three-dimensional winding device for flat wires. The vertical winding process of the flat wire is to surround the skeleton along the axial direction of the skeleton, so that multi-layer flat wires are superimposed. The vertical winding device of the present invention combines the winding component and the clamping component into one, and one folding component can perform two folding processes, so that the structure of the vertical winding device is simpler and the occupied space is effectively reduced.

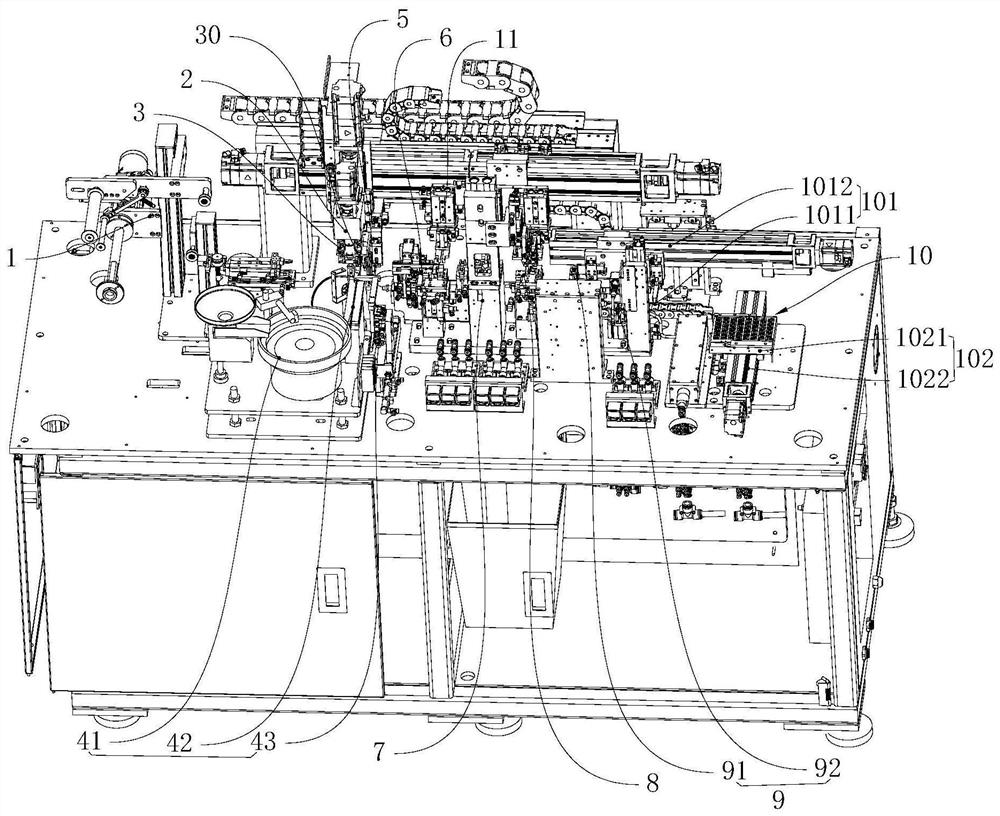

[0049] see figure 1 , the flat wire vertical winding device includes a wire feeding assembly 1, a winding assembly 2, a first clamping assembly 3, a second clamping assembly 30, a skeleton feeding assembly 4, a cutting assembly 5, a first folding assembly 6, and a corner cutting assembly. Component 7, second folding line component 8, flip positioning component 9, unloading component 10 and ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com