Automatic shaping test line for horizontal transformer

A transformer and test line technology, applied in photovoltaic power generation, sorting and other directions, can solve the problems of inconsistent steel sheet tightness, low operating efficiency, time-consuming and labor-intensive, etc., to overcome upstream and downstream connection waiting, improve position stability, and the overall structure is compact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

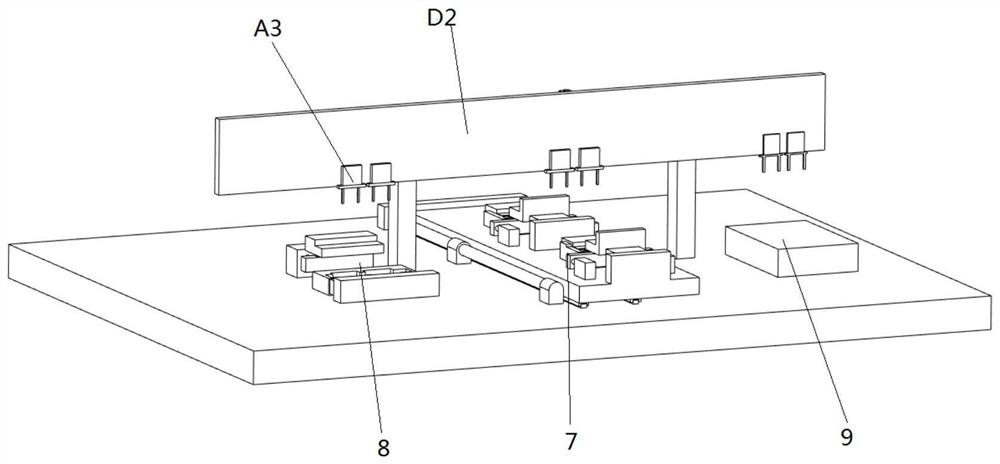

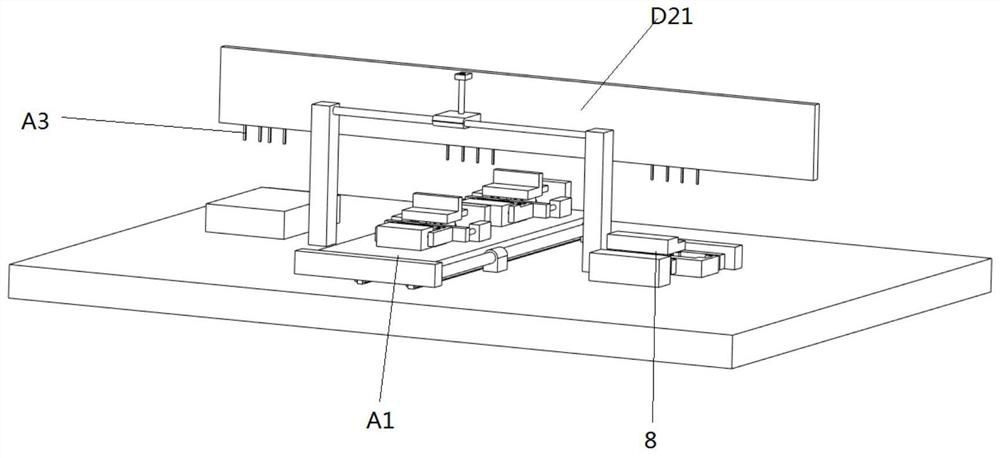

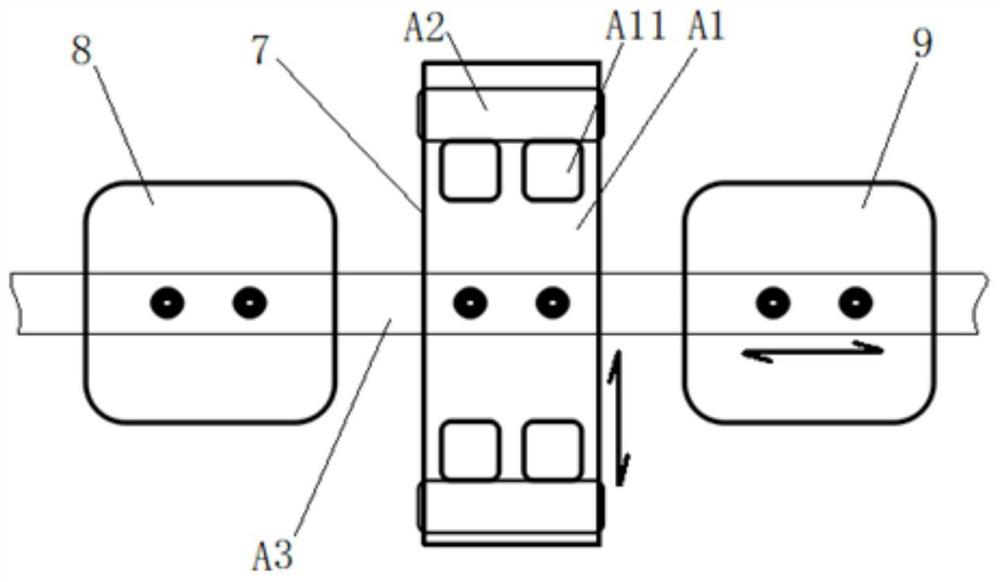

[0033] as attached Figure 1-10 : A horizontal transformer automatic shaping test line, comprising a shaping device 9, a withstand voltage testing device 7 and an electrical performance testing device 8 arranged sequentially; the shaping device 9, a withstand voltage testing device 7 and an electrical performance testing device 8 A conveying mechanism D2 is arranged between them; the shaping device 9 includes a jig 1; the jig 1 includes a bottom plate 11 and an abutment portion 12; the abutment portion 12 includes a T-shaped back plate 121 and a partition plate 122; the first notch 13 and the second notch 14 are provided on both sides of the partition 122; the first shaping assembly 2 and the second shaping assembly 3 are also movable around the fixture 1; the first The active path of the shaping assembly 2 and the active path of the second shaping assembly 3 are perp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com