Flat mop suite

A flat mop and mop technology, which is applied in the field of mop buckets, can solve the problems of inconvenient cleaning, unsatisfactory use effect, affecting the normal movement of the piston, etc., and achieves the effect of reducing the number of parts, avoiding sanitary dead corners, and reducing assembly steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

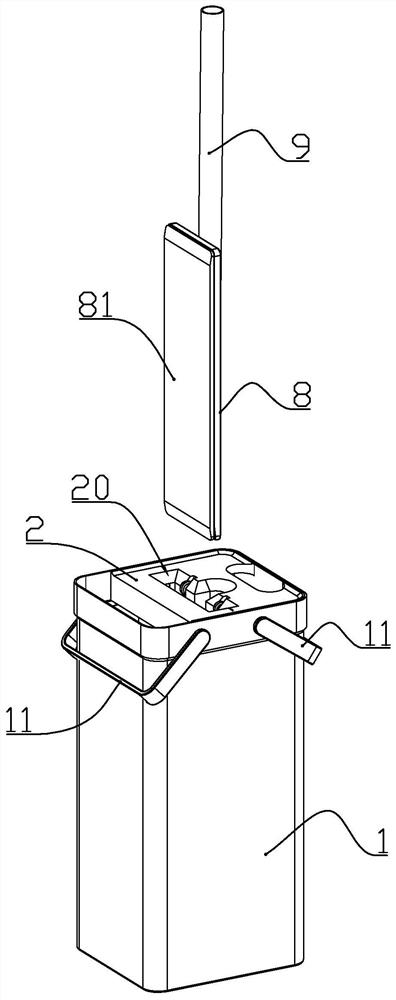

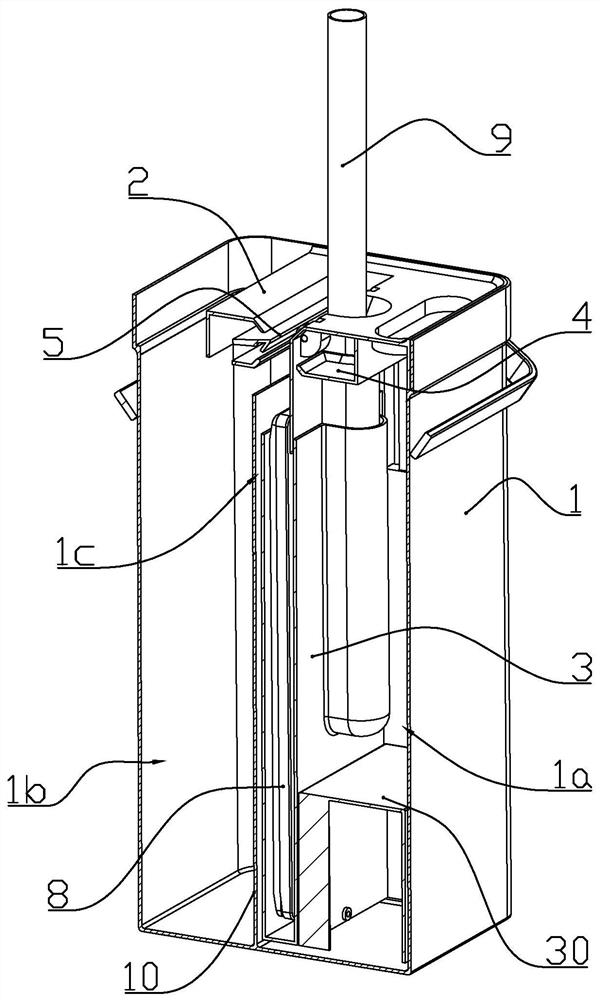

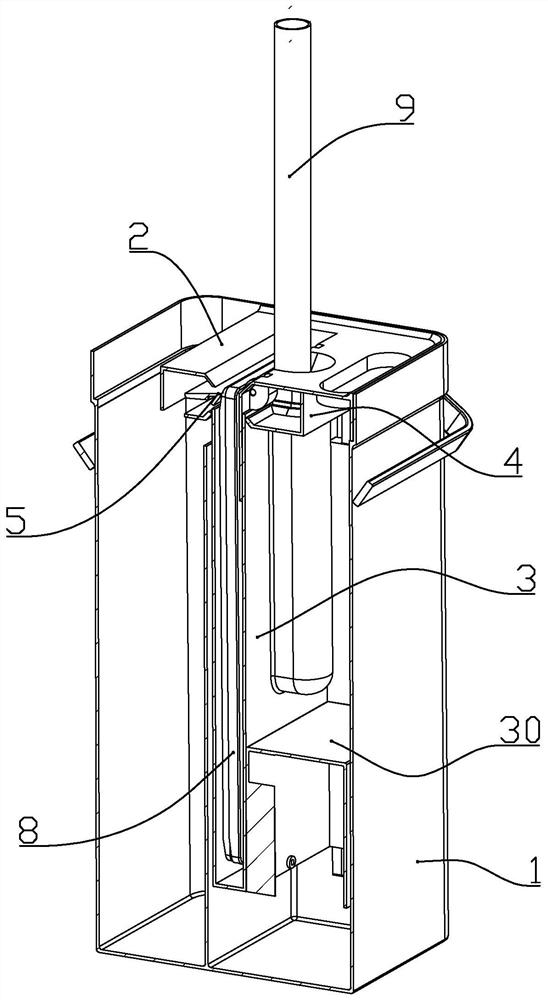

[0024] according to Figure 1 to Figure 8 As shown, this embodiment is a flat mop kit, including a mop and a mop bucket; the mop includes a mop board with wipes, and a mop bar movably connected with the mop board.

[0025] The wiper is a mop or collodion of a common flat mop on the market. A rotary joint is rotatably connected to the middle of the mop board, the lower end of the mop rod is rotatably connected to the rotary joint, and the rotation axis a of the mop rod and the rotary joint and the rotation axis b of the mop plate and the rotary joint are perpendicular. When the mop needs to be washed or squeezed dry, turn the mop plate to figure 1 Shown approximately parallel to the mop bar. The upper end of the mop board and the upper end of the wipes described below generally refer to the end of the mop bar that is placed vertically and the mop board is turned to be parallel to the mop bar and faces upward.

[0026] The mop bucket includes a bucket body 1 and an inner buc...

Embodiment 2

[0058] combine Figure 9 to Figure 11 As shown in the figure, the difference between this embodiment and Embodiment 1 is that a water guide tube 6 is arranged in the clean water container, the inner barrel is slid in the water guide tube along the longitudinal direction, and the inner wall of the water guide tube is connected to the outer wall of the inner barrel. A water supply channel 1c is formed therebetween; and the water guide tube is provided with a water passage 61, which makes the water guide tube communicate with the clean water chamber. In this case, the inner tub itself acts as the flow blocking member, that is, when the side wall of the inner tub blocks the water passage, it prevents or slows the rise of the water level in the clean water chamber.

[0059] Further, the water guide tube described in the figure is a structure that is detachably installed in the barrel. In some other embodiments, the water guide tube can be integrally formed with the tub body. That...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com