A kind of defoamer for carboxyl nitrile latex and preparation method thereof

A technology of carboxyl nitrile butadiene latex and defoamer, which is applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve the problem of poor foam suppression effect and stability, latex gel agglomeration, poor defoaming effect, etc. problem, to achieve the effect of excellent foam suppression performance, less dosage and fast defoaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

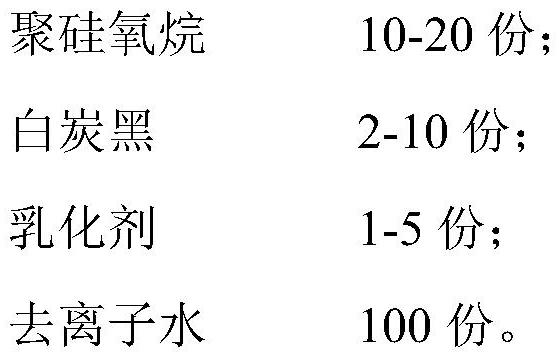

[0018] Described carboxyl nitrile latex defoamer is made of the following raw materials by weight:

[0019]

[0020] Its preparation process is as follows:

[0021] Add polysiloxane and white carbon black to the reaction kettle in turn, heat up to 110°C, react for 6 hours, cool down to 60°C, add emulsifier and deionized water, react for 50 minutes, and then drop to room temperature to obtain the product.

Embodiment 2

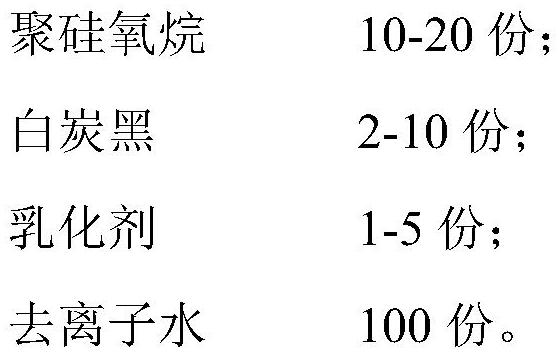

[0023] Described carboxyl nitrile latex defoamer is made of the following raw materials by weight:

[0024]

[0025] The preparation process is as follows: add polysiloxane and white carbon black in sequence to the reaction kettle, heat up to 140°C, react for 5 hours, cool down to 80°C, add emulsifier and deionized water, react for 40 minutes, and then drop to room temperature product.

Embodiment 3

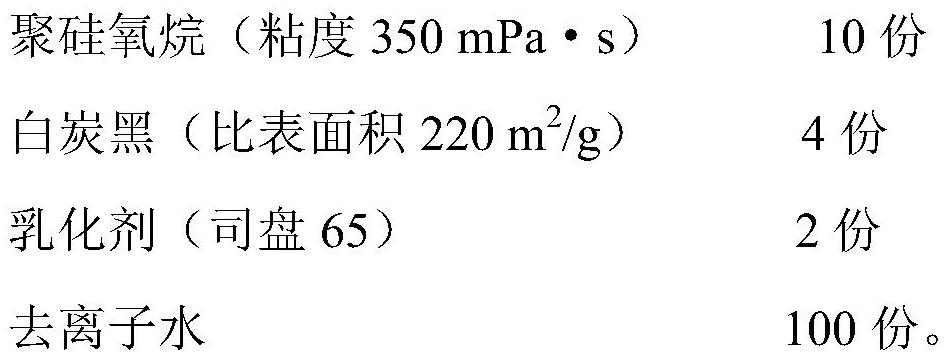

[0027] Described carboxyl nitrile latex defoamer is made of the following raw materials by weight:

[0028]

[0029]

[0030] The preparation process is as follows: adding polysiloxane and white carbon black in sequence to the reaction kettle, heating up to 130°C, reacting for 5 hours, cooling to 80°C, adding emulsifier and deionized water, reacting for 50 minutes, and then dropping to room temperature product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com