Spiral sand washer used for furnace slag production

A technology of sand washing machine and spiral, which is applied in the field of spiral sand washing machine for slag production, which can solve the problems of manual opening of the sand discharge port and achieve the effect of improving work efficiency and reducing the possibility of idling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

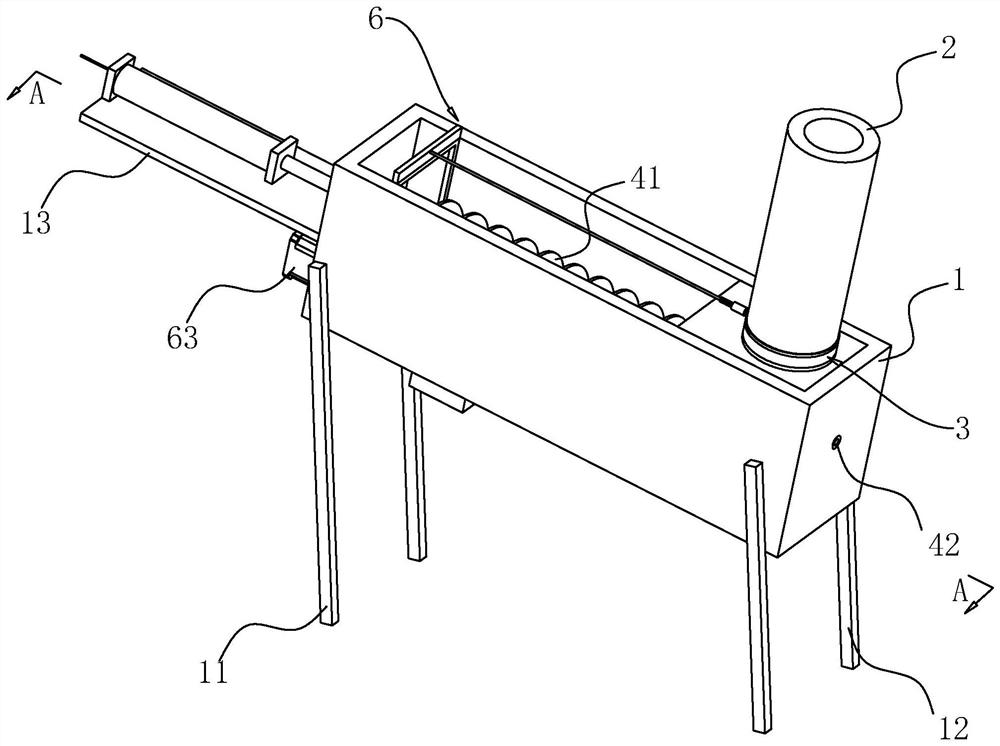

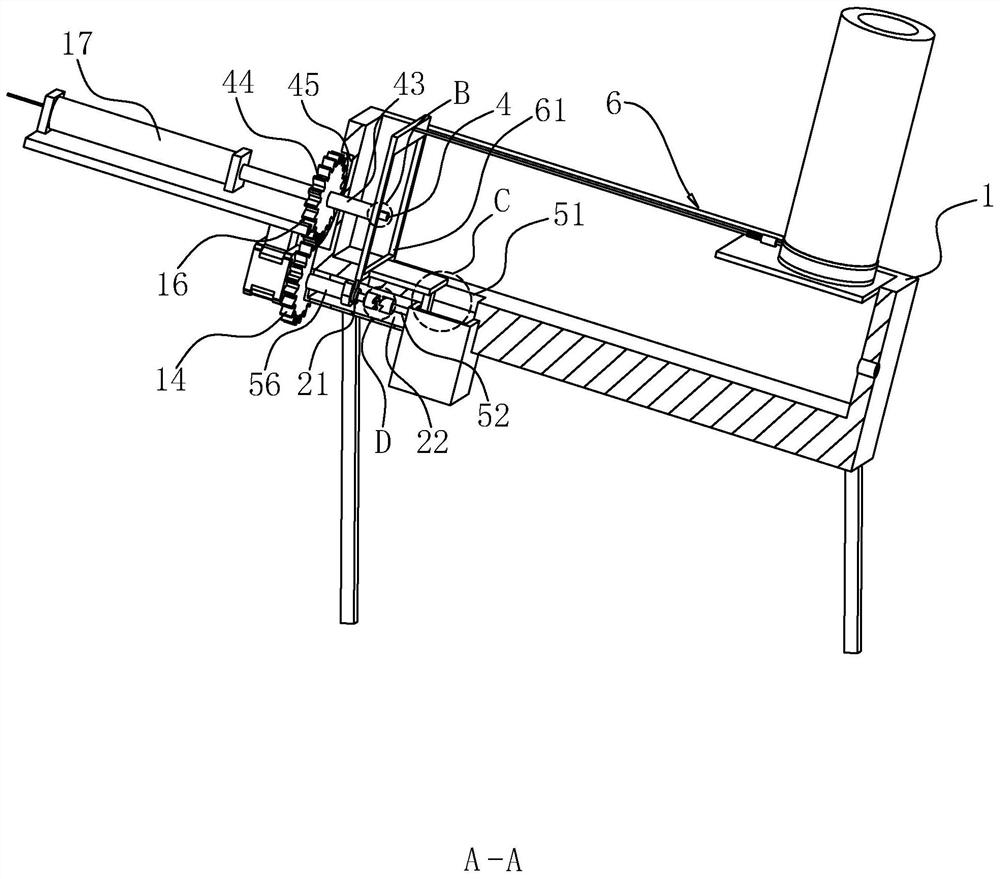

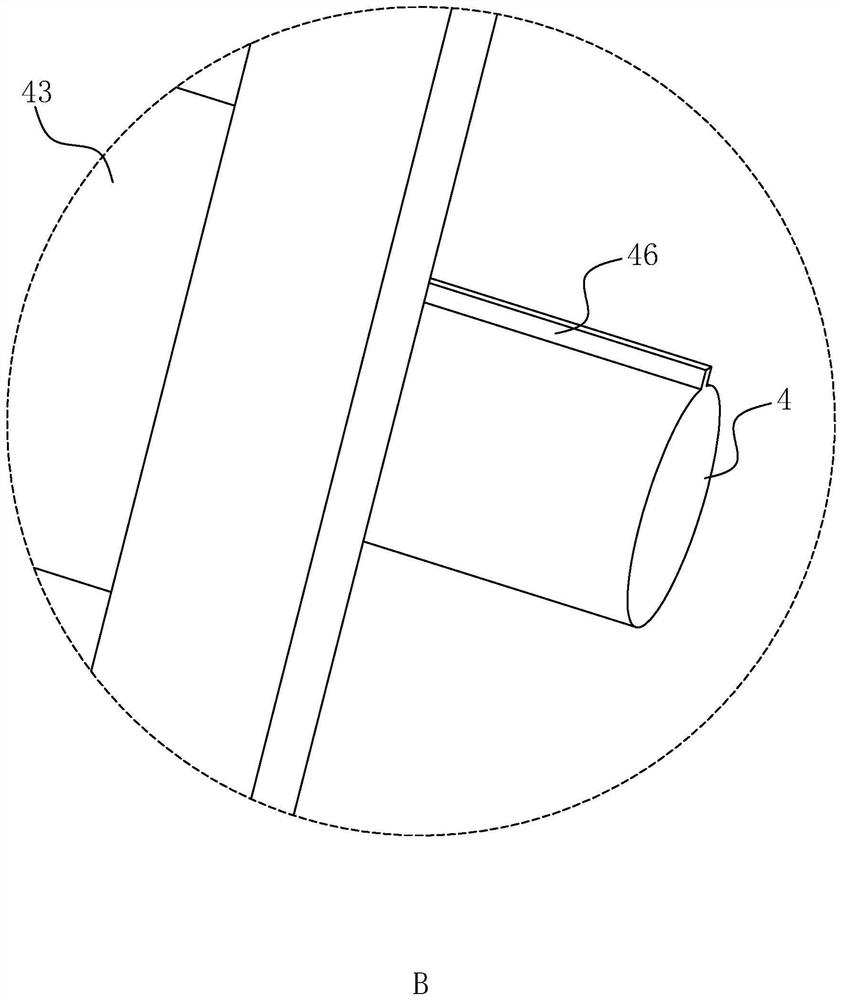

[0034] The following is attached Figure 1-6 The application is described in further detail.

[0035] The embodiment of the present application discloses a spiral sand washing machine for slag production. refer to figure 1 and figure 2 , The spiral sand washing machine includes a rectangular casing 1 and a first pole 11 and a second pole 12 fixed on the bottom of the casing 1 . The length of the first pole 11 is longer than that of the second pole 12, so that the casing 1 is arranged obliquely. A feed pipe 2 is fixed on the top of the casing 1, and the feed pipe 2 is located above the second support rod 12; a valve assembly 3 is provided at the discharge end of the feed pipe 2. After the material enters the casing 1 from the feed pipe 2, it moves upward along the inclined direction of the casing, so that the moisture in the material flows out downward during the sand washing process. A supporting plate 13 is fixed on one side of the casing 1 . A motor 63 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com