Device for sorting diamond tool bits with different thicknesses

A diamond cutter head and screening technology, which is used in classification, solid separation, chemical instruments and methods, etc., can solve the problems of low efficiency, labor-intensive, easy to wrong sorting, etc., and achieve the effect of convenient and accurate screening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

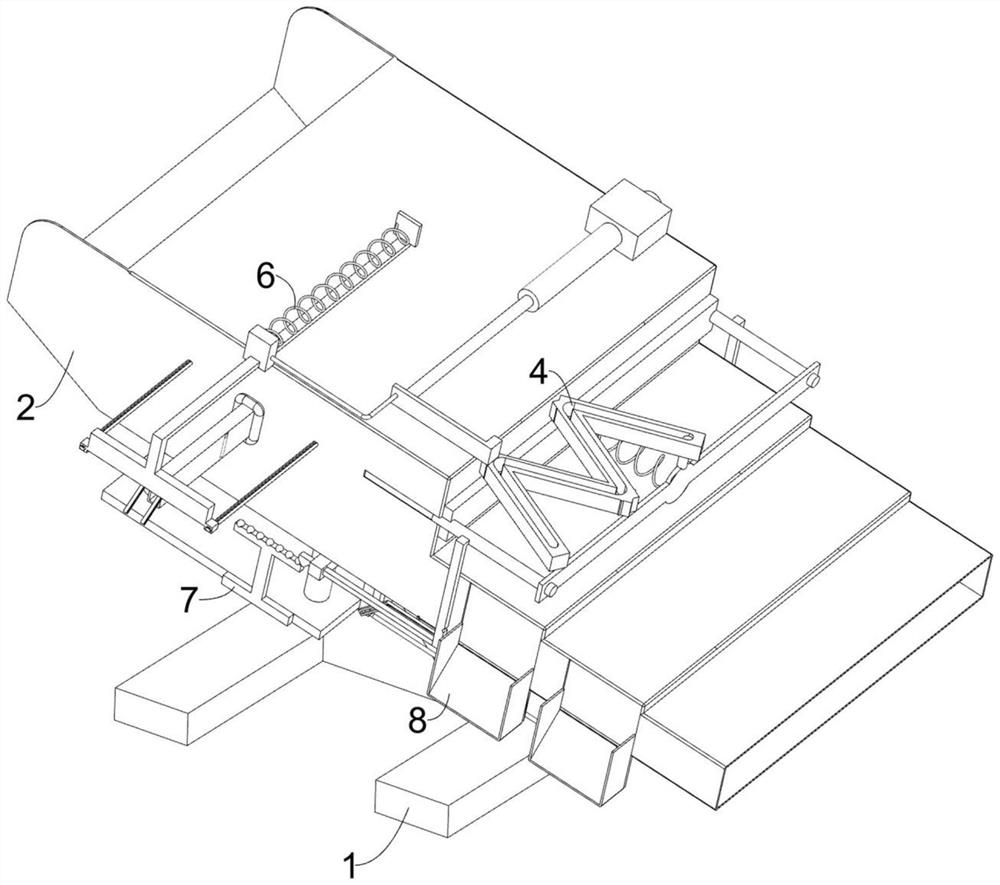

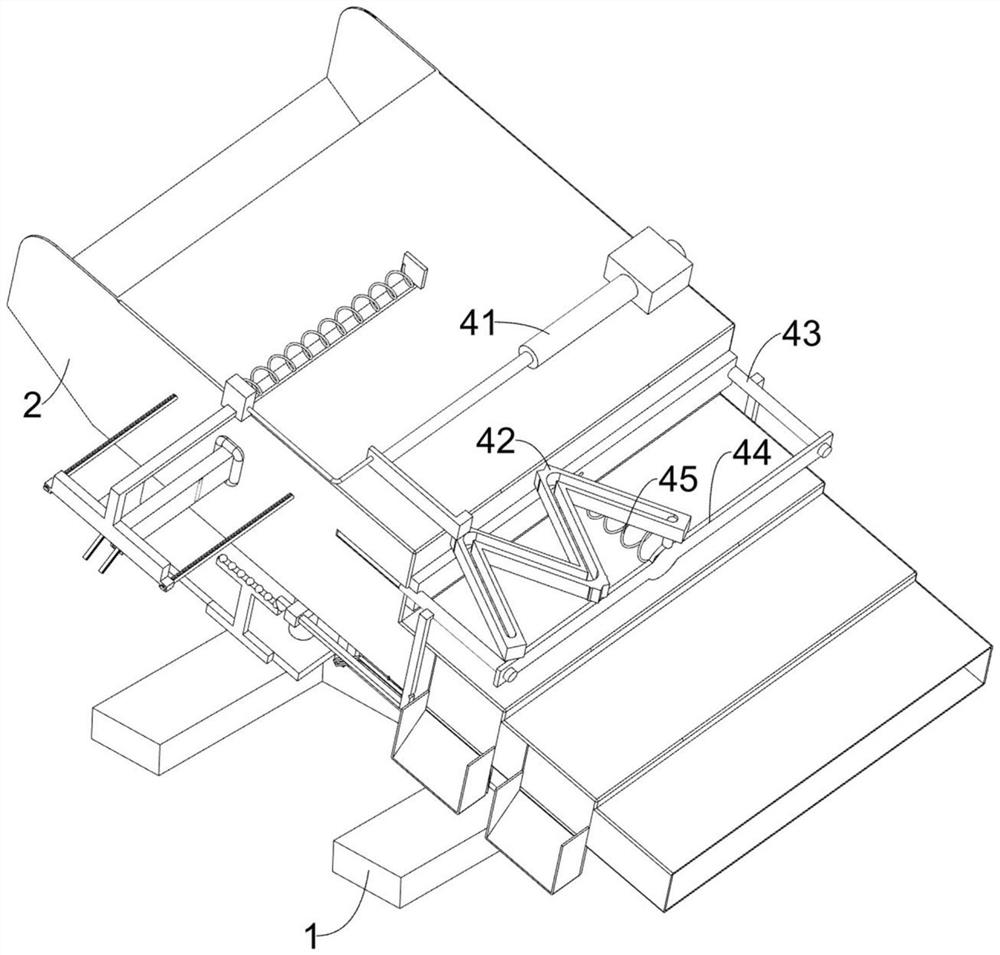

[0027] A device for sorting diamond bits of different thicknesses, such as Figure 1-9 As shown, it includes a support base 1, an inclined sorting frame 2, a first spring 3, a push-down assembly 4 and a screening control assembly 5. The inclined sorting frame 2 is slidably connected to the top of the support base 1, and the inclined sorting frame 2 is The first spring 3 is connected, and the other end of the first spring 3 is connected to the support base 1. The push-down assembly 4 is arranged on the inclined sorting frame 2, and the push-down assembly 4 is used to vertical the diamond head on the upper part of the inclined sorting frame 2. Push down, the screening control assembly 5 is arranged on the inclined sorting frame 2, and the screening control assembly 5 is used to make the diamond cutter heads on the inclined sorting frame 2 slide to the right in batches.

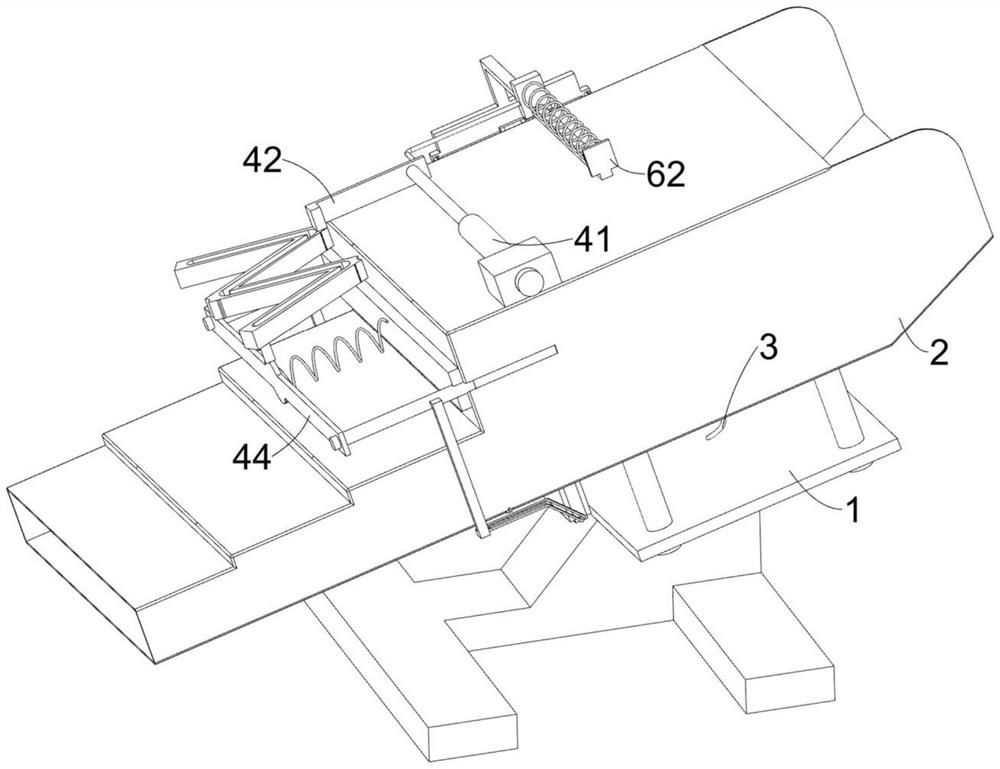

[0028] Push down assembly 4 and include electric push rod 41, W groove plate 42, the first slide push frame 4...

Embodiment 2

[0034] On the basis of Example 1, such as Figure 7-8 As shown, it also includes an anti-accumulation assembly 6. The anti-accumulation assembly 6 is arranged on the inclined sorting frame 2. The anti-accumulation assembly 6 is used to prevent the diamond bits from accumulating on one side of the inclined sorting frame 2. The anti-accumulation assembly 6 includes Pushing frame 61, slotted sliding frame 62, the third spring 63, slotted sliding block 64, the third sliding pushing frame 65 and resistance ring 66, pushing frame 61 is connected on the W grooved plate 42, and slotted sliding frame 62 sliding type Connected to the push frame 61, the slotted sliding frame 62 is used to push the third sliding push frame 65 to move towards the direction close to the electric push rod 41, the slotted sliding frame 62 is slidingly connected with the inclined sorting frame 2, the slotted sliding frame 62 is connected with a third spring 63, the other end of the third spring 63 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com