Accurately quantitative dibber

An on-demand machine and precision technology, applied in the direction of single-seed seeder, seeder parts, etc., can solve the problems affecting the high and stable yield of rice, poor ventilation and light transmission, and poor lodging resistance, so as to achieve good ventilation and light transmission performance and production. High efficiency and good lodging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

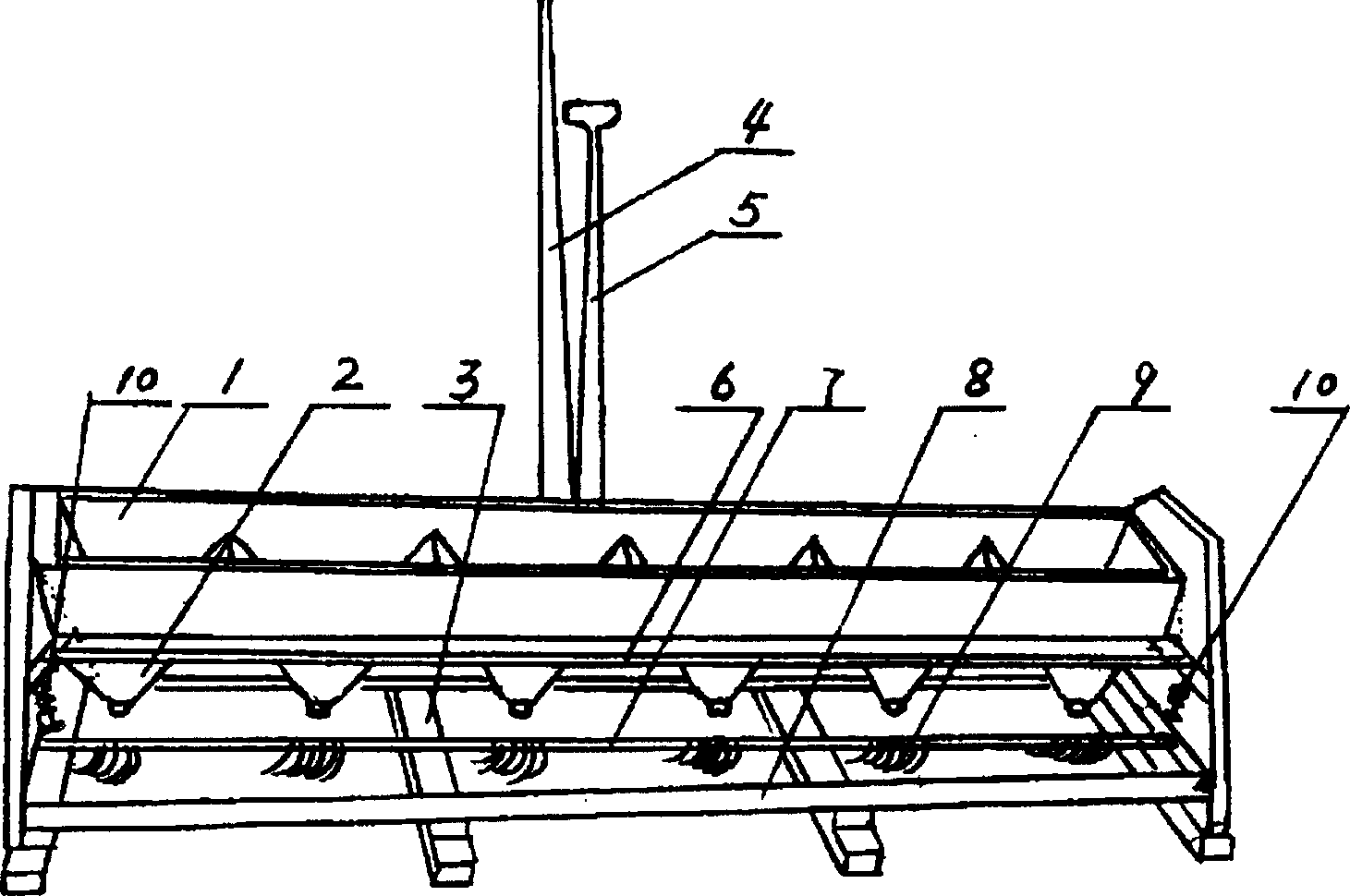

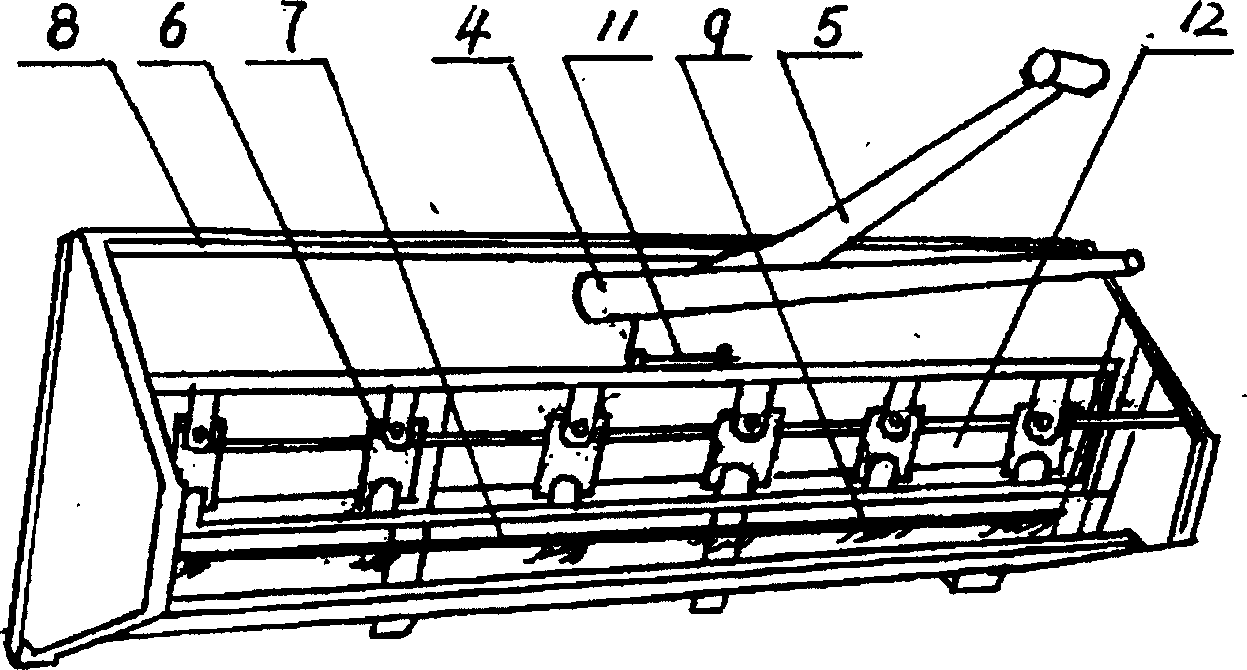

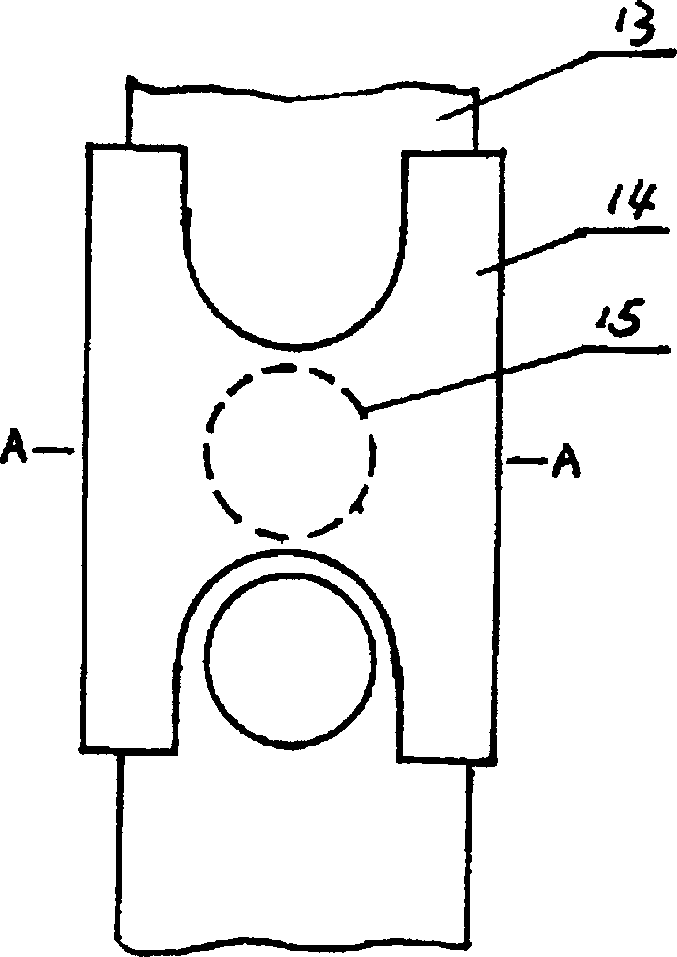

[0014] Embodiment 1: with reference to attached figure 1 , attached Figure 3-7 . Precision on-demand seeding machine, frame chassis assembly 8 bottoms are provided with sliding drain ditching edge 3, and purpose is to once finish paddy planting and field ditching two works, sinks in the field in order to facilitate seed. Several inoculation hoppers 2 are positioned laterally on the frame chassis assembly, and the inoculation hoppers 2 are connected to the translational seeding assembly 6, and the translational seeding assembly is lifted or lowered under the action of the screw or bolt lifting mechanism 10 located thereon. The purpose is to adapt to the direct sowing of the field just after remediation, and to avoid the contact of the seeding port with the field. The distance between the inoculation hoppers is adjustable. Above the inoculation hopper is a translational seeding assembly 6 with a guide rail. The translational seeding assembly with a guide rail is composed of a...

Embodiment 2

[0015] Embodiment 2: with reference to attached Figure 2-8 . Precision on-demand seeding machine, frame chassis assembly 8 bottoms are provided with sliding drain ditching edge 3, and purpose is to once finish paddy planting and field ditching two works, sinks in the field in order to facilitate seed. Several inoculation tubes 2 are positioned laterally on the frame chassis assembly, and the inoculation tubes 2 are connected to the translational seeding assembly 6, and the translational seeding assembly is lifted or lowered by the action of the screw or bolt lifting mechanism 10 located thereon. The purpose is to adapt to the direct sowing of the field just after remediation, and to avoid the contact of the seeding port with the field. The distance between the inoculation tubes is adjustable. Above the inoculation tube is a translational seeding assembly 6 with a guide rail. The translational seeding assembly with a guide rail is composed of a guide rail and a translational ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com