Bar movement control device of heading machine

A motion control device and heading machine technology, applied in manufacturing tools, other manufacturing equipment/tools, metal processing equipment, etc., can solve the problems of uneven friction, rotational offset of metal bars, bending of metal bars, etc. To achieve the effect of reducing the offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

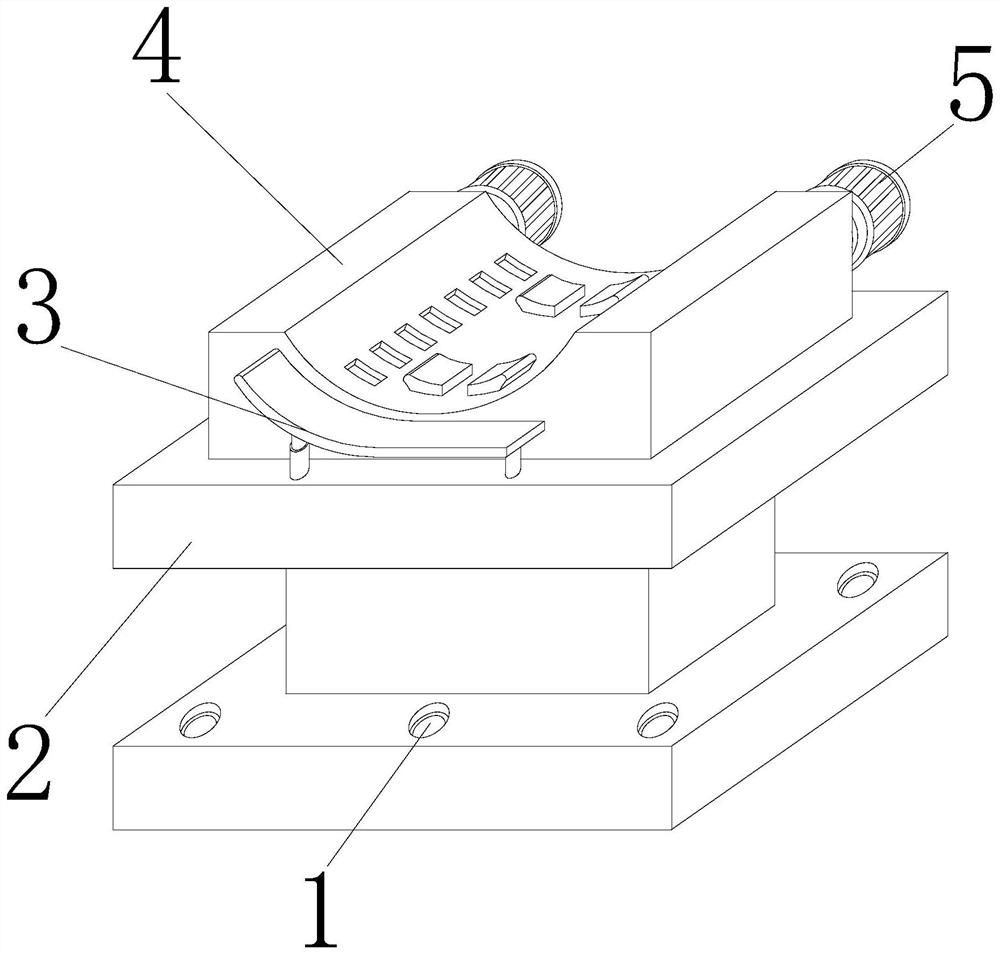

[0028] Such as Figure 1-Figure 6 As shown, the present invention provides a heading machine bar movement control device, its structure includes a connection hole 1, a mounting seat 2, a push plate 3, an engaging device 4, and a driver 5, and the connection hole 1 is opened at the lower end of the mounting seat 2 Around the surroundings, the bottom end of the push plate 3 is embedded and fixed at the front end of the upper part of the mounting base 2, the bottom end of the engaging device 4 is welded to the center of the upper surface of the mounting base 2, and the front end of the driver 5 is driven and matched to the engaging device 4 sides of the rear end.

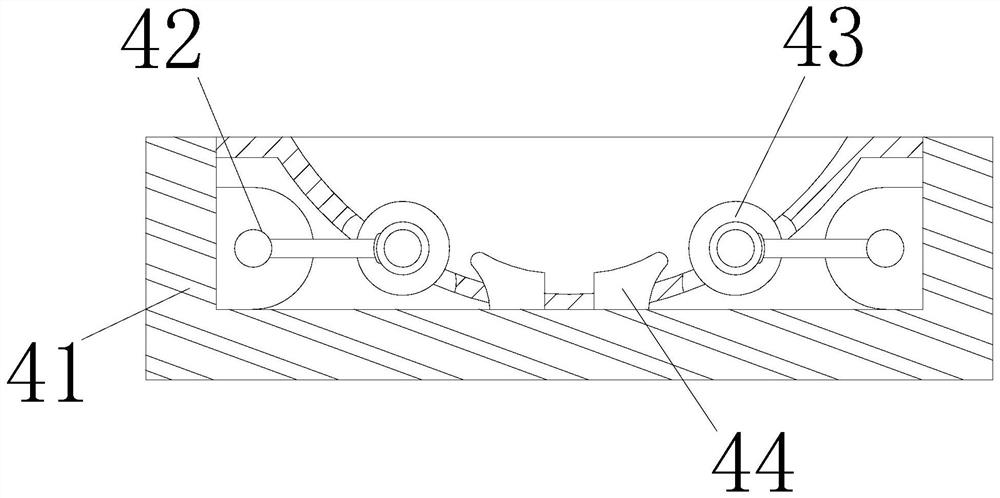

[0029] The engaging device 4 includes an outer cover 41, a torsion bar 42, a rotating device 43, and a receiving block 44. The side ends of the torsion bar 42 are embedded on both sides of the inner wall of the outer cover 41, and the front end of the rotating device 43 is hinged to the torsion bar 42. At the side end...

Embodiment 2

[0037] Such as Figure 7-Figure 8 Shown:

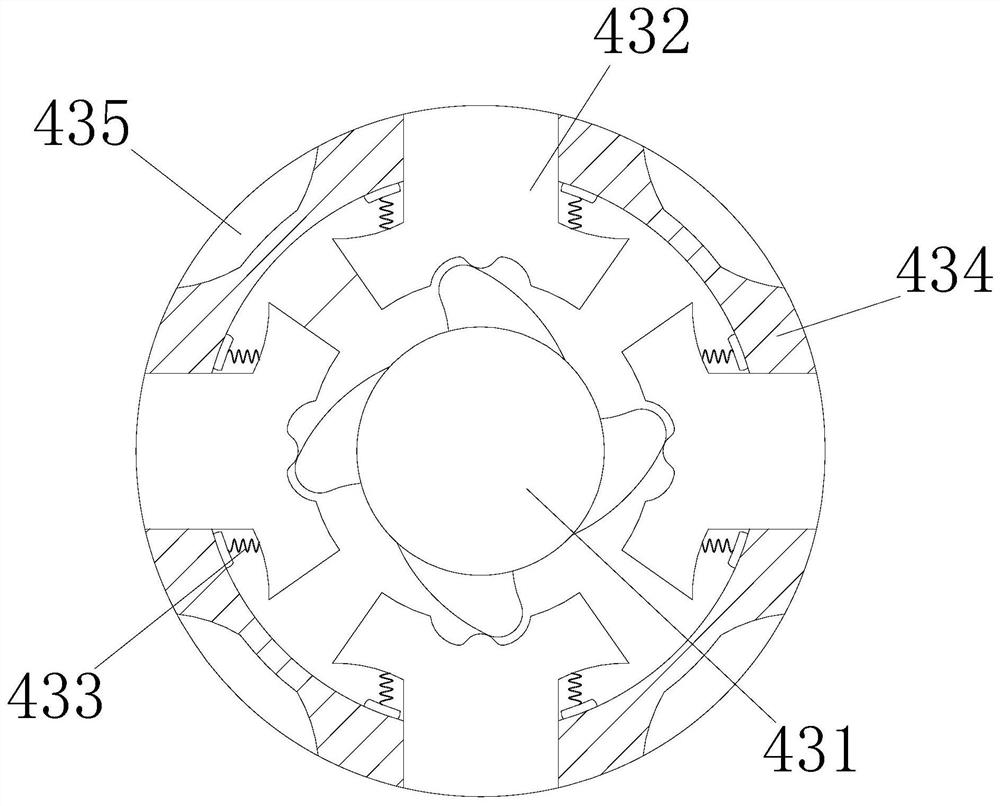

[0038] Wherein, the grinding mechanism 435 includes a fixed piece c1, an engaging piece c2, a chute c3, and a grinding block c4. The lower end wall of the engaging piece c2 is embedded and connected to the upper surface of the fixing piece c1. Inside the upper wall of the engaging piece c2, the bottom end of the grinding block c4 is embedded in the upper wall surface of the engaging piece c2, and the chute c3 is an inclined straight groove structure, which enables it to accommodate more More fallen rust, so as to prevent the rust from falling off and covering the surface of the grinding block c4, which will affect the subsequent grinding.

[0039] Wherein, the grinding block c4 includes a bottom plate c41, an upper cover c42, a grinding ball c43, and a cone c44. Connected to the upper end wall surface of the upper cover c42, the lower end of the cone block c44 is embedded and connected to both sides of the upper wall surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com