Rapid cooling device for injection mold

A rapid cooling, injection mold technology, applied in the field of mold cooling, can solve the problems of low production efficiency, difficult heat dissipation of injection molds, slow product curing, etc., to speed up water cooling efficiency, avoid worker burns, and increase the effect of contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

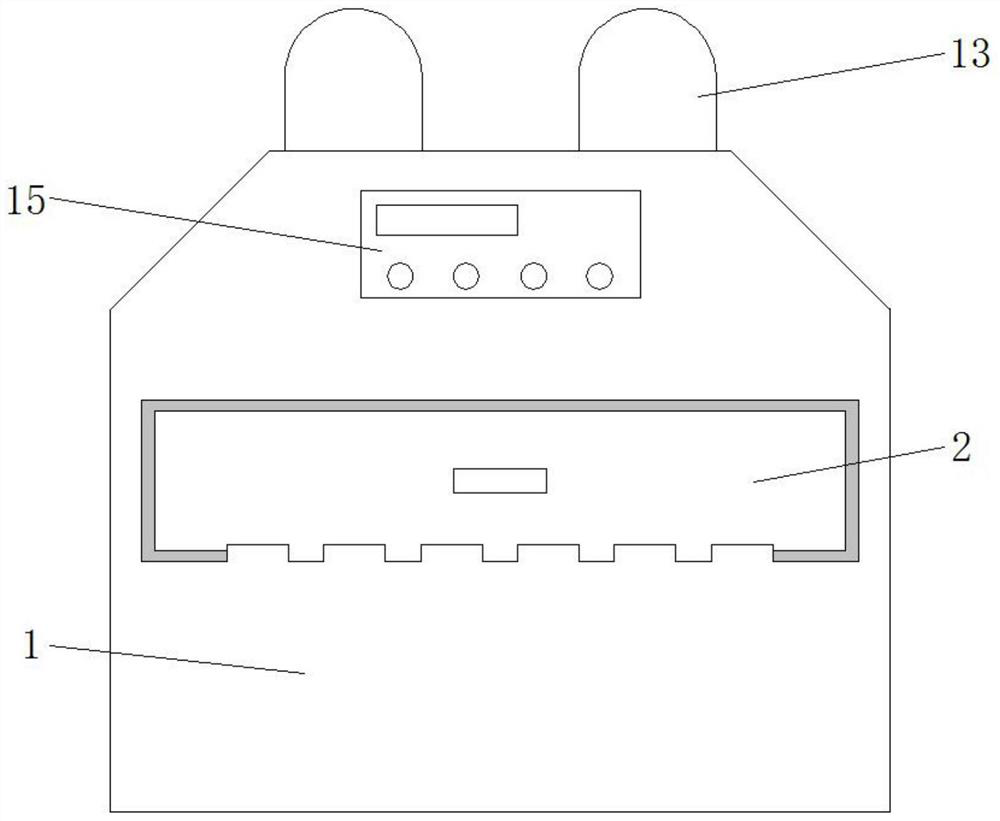

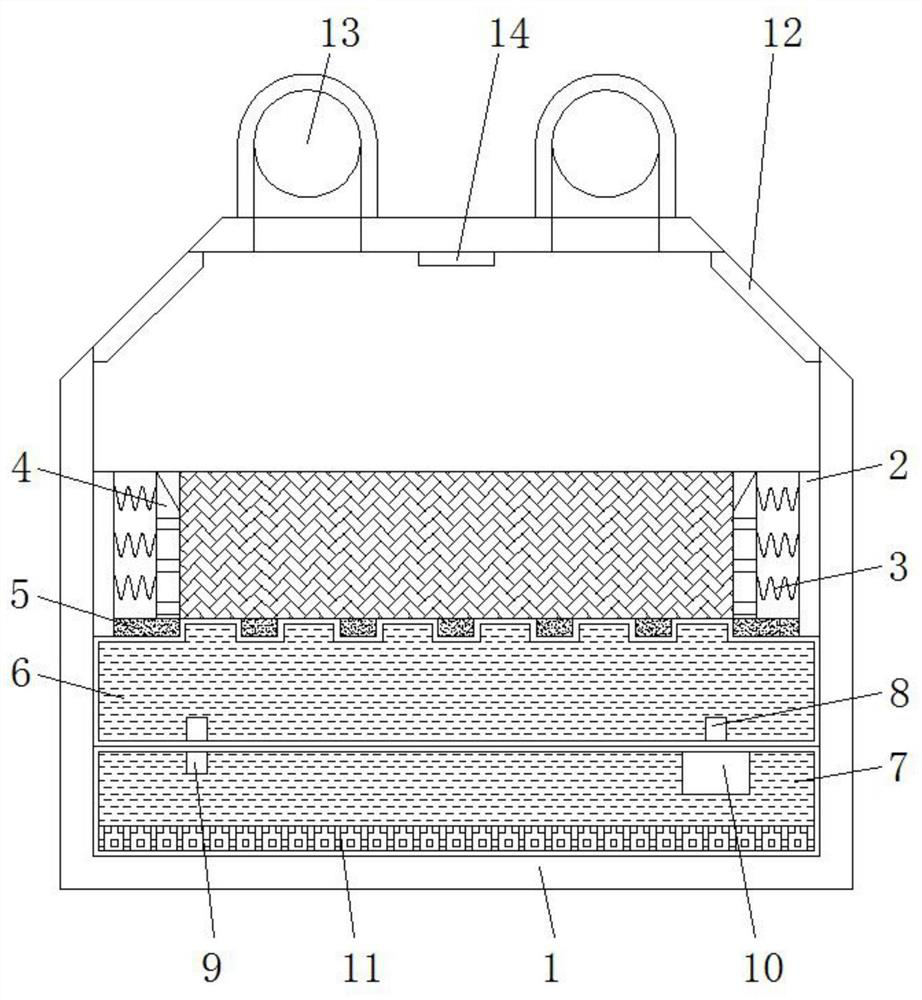

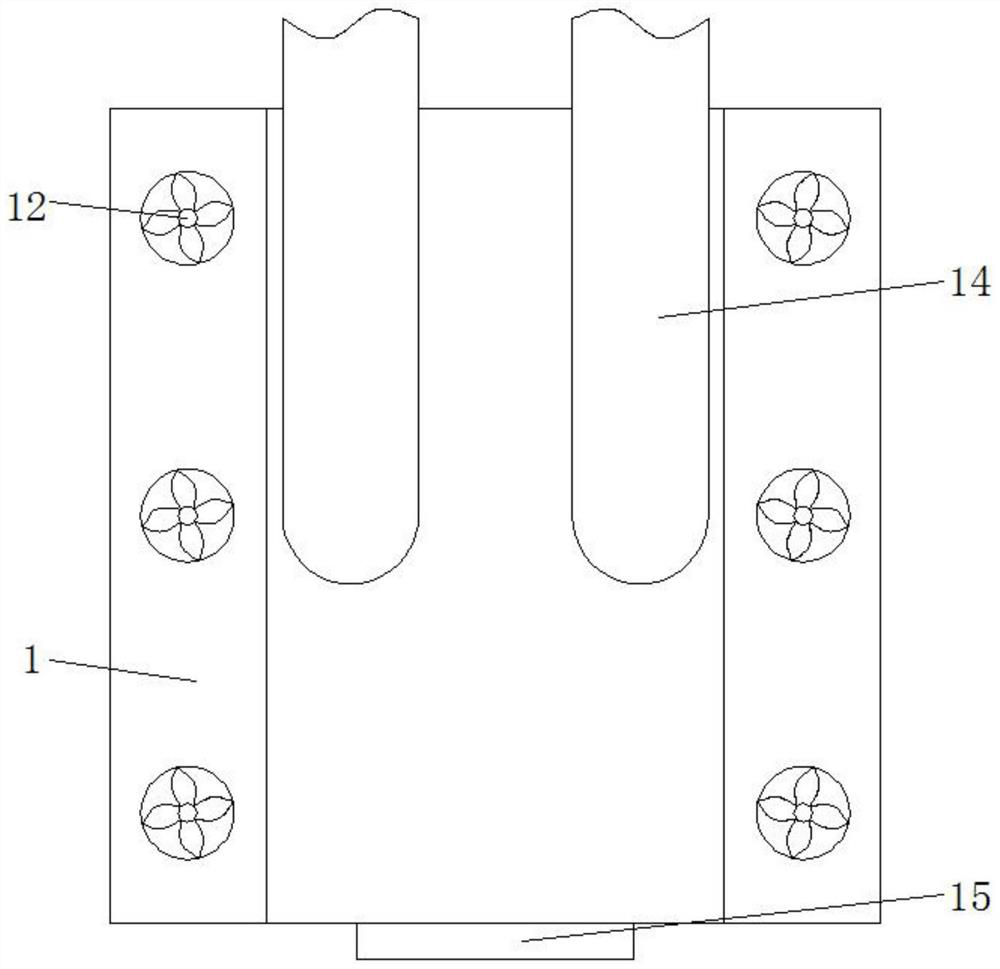

[0019] Example: refer to Figure 1-3 , a rapid cooling device for injection molds, including a casing 1, a storage cabinet 2 is slidably connected to the casing 1, and several springs 3 are connected to the inner walls of the two ends of the storage cabinet 2, and one end of the spring 3 is connected to and installed with The fixed plate 4, the bottom of the storage cabinet 2 is provided with a heat conducting plate 5, and the bottom of the heat conducting plate 5 is provided with a circulating water tank 6, the bottom of the circulating water tank 6 is provided with a cooling tank 7, and a water inlet pipe 8 is connected between the circulating water tank 6 and the cooling tank 7 And the drain pipe 9, the water inlet pipe 8 is connected to the water pump 10 through the cooling box 7, the inner wall of the bottom of the cooling box 7 is laid with a condensing plate 11, the two sides of the casing 1 are connected and installed with several exhaust fans 12, and the top of the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com