Hollow casting type rubber bushing assembly

A technology of rubber bushings and castings, applied to vehicle parts, cantilevers mounted on pivots, suspensions, etc., can solve the problem that the self-weight of the steel inner core is not reduced, and the rear shock-absorbing rubber bushing assembly is lightweight. Insignificant and other problems, to achieve the effect of reducing overall weight, reducing production processes, and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

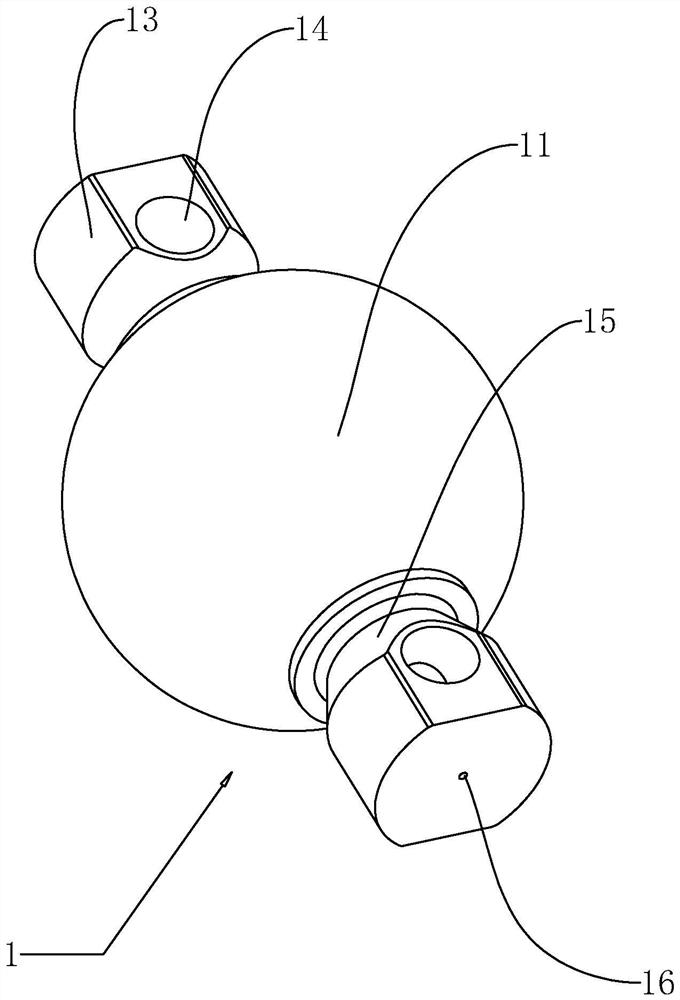

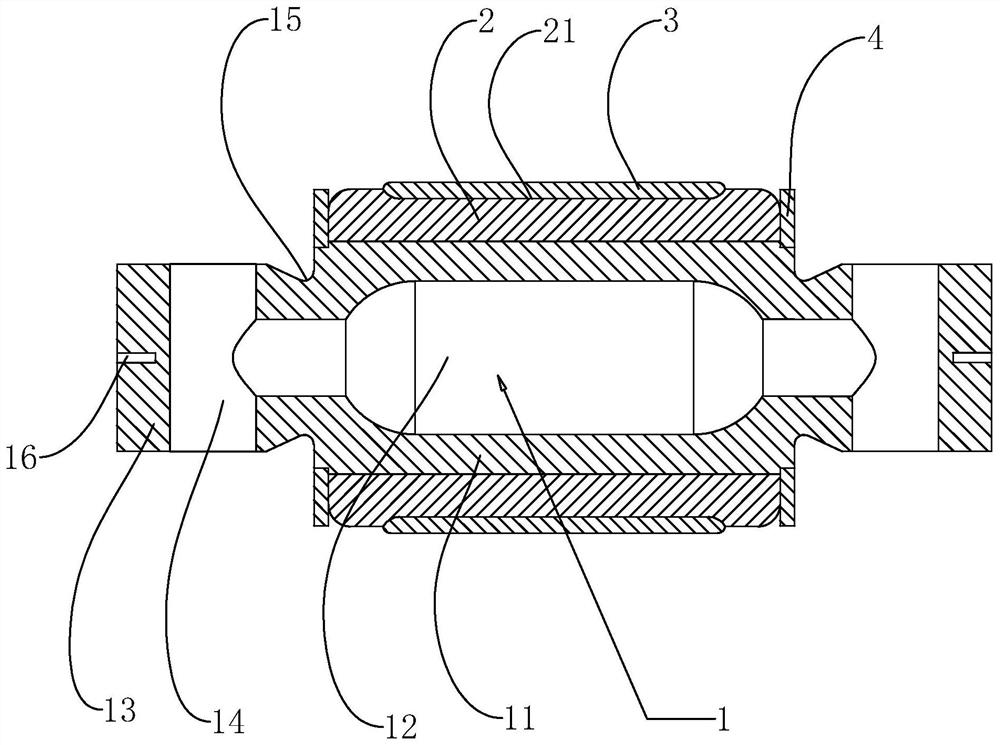

[0039] refer to figure 1 and figure 2 , a hollow casting type rubber bushing assembly, including the joint ball pin 1, the joint ball pin 1 is made of rubber material as a whole, and the rubber material is elastic and deformable. The joint ball pin 1 includes a ball pin body 11. The ball pin body 11 has a spherical structure without external force. The ball pin body 11 is provided with a hollow cavity 12, and the central cavity is placed at the center of the ball pin body 11. . Through the arrangement of the hollow cavity 12, the dead weight of the ball pin body 11 is greatly reduced, and the weight reduction effect is realized.

[0040] refer to figure 1 , the two ends of the ball pin body 11 are integrally connected with ball pin ends 13 respectively, the two ball pin ends 13 and the ball pin body 11 are on the same linear position, and the shape and size of the ball pin ends 13 are smaller than the ball pin body 11 shape and size. The ball pin end 13 is provided with ...

Embodiment 2

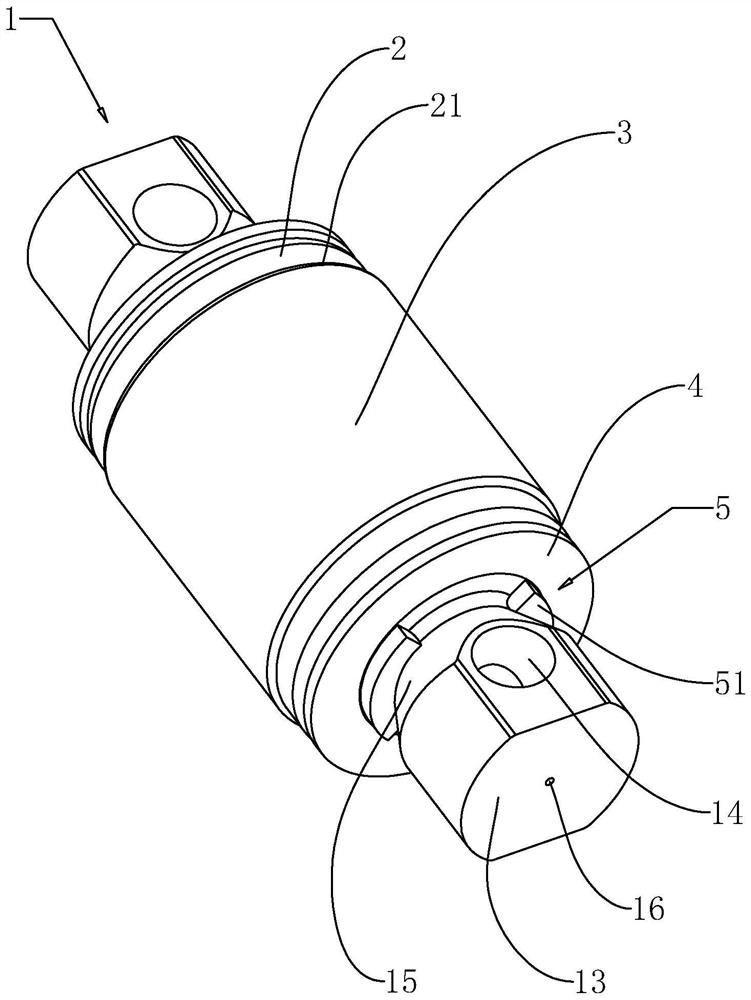

[0053] refer to figure 2 and Figure 4 The difference between the second embodiment and the first embodiment lies in the difference of the limit mechanism 5, the limit mechanism 5 includes a snap spring 52, the inner diameter of the snap spring 52 is smaller than the inner diameter of the end cover 4, and the operator uses the snap spring 52 to clamp and other related circlip 52 installation tools, the circlip 52 is installed between the end cover 4 and the ball pin body 11, so that the circlip 52 is placed in the rotation groove 15, and the end face of the circlip 52 is directly close to the ball pin body 11. The end surface of the pin end 13 is connected against each other, and the ball pin body 11 is further limited between the two end caps 4 through the cooperation of the end cover 4 and the snap spring 52, and finally the rotation of the ball pin body 11 in the bushing shell 2 is improved. stability.

[0054] The implementation principle of the second embodiment of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com