Automatic tow stacking mechanism

A tow, automatic technology, applied in the field of raw silk packing, can solve the problems of inability to achieve the pre-oxidation connection of raw silk, waste of human resources and process, and easy occurrence of hidden dangers, so as to eliminate the risk of exothermic fire and promote carbon fiber production. Integrate, improve the effect of working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

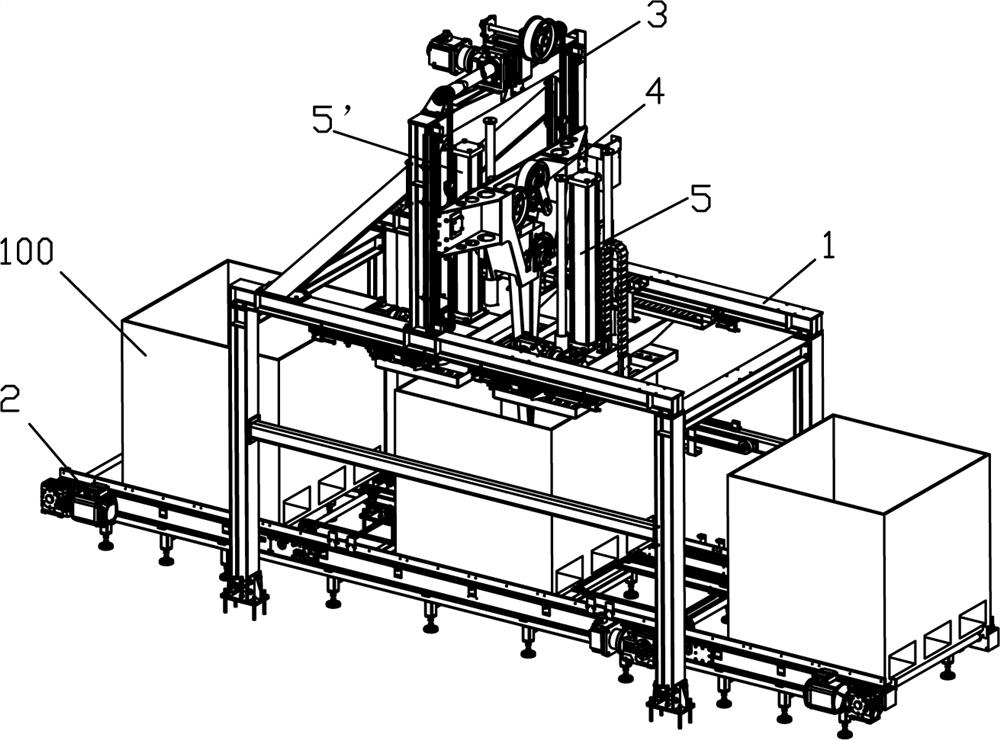

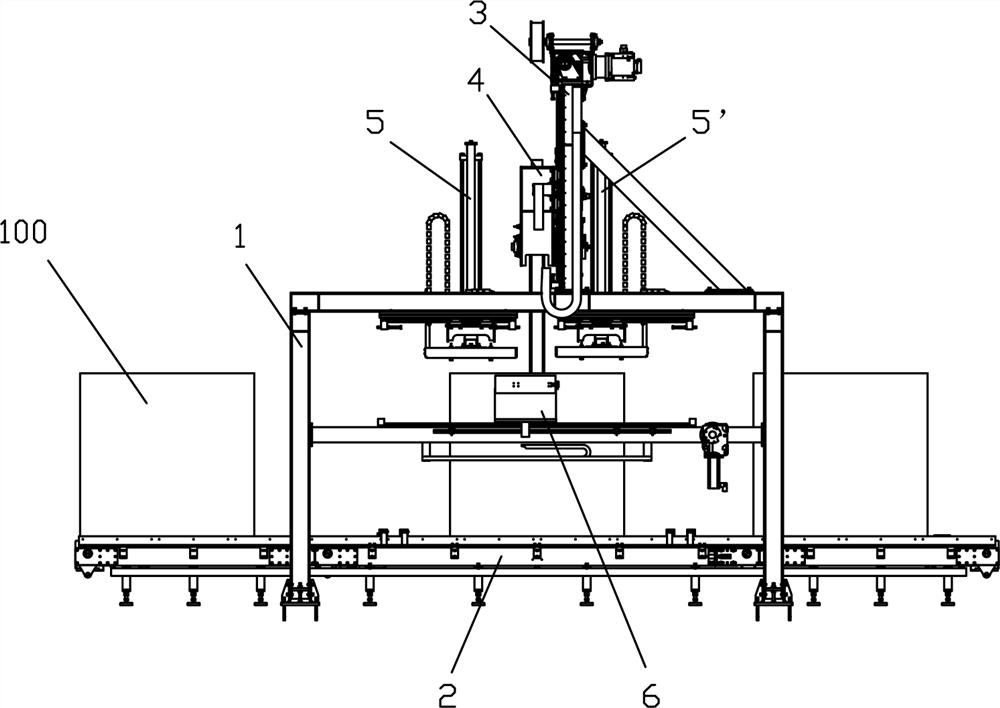

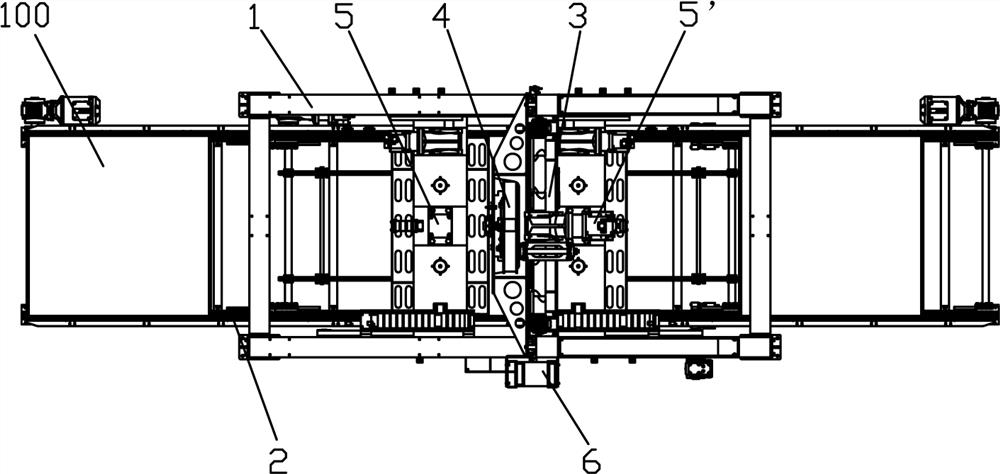

[0027] see Figure 1 to Figure 10 , a tow automatic stacking mechanism according to the present invention, which includes:

[0028] The fixing frame 1 is a rectangular frame structure, straddling above a conveying line body 2;

[0029] Lifting mechanism 3, including:

[0030] A gantry frame 31 is arranged on the upper end of the fixed frame 1;

[0031] Two guide rails 32 and their upper sliders, the two guide rails 32 are respectively arranged on the front sides of the frame on both sides of the gantry 1;

[0032] Two transmission assemblies 33, 33 ' are respectively arranged on the inner sides of the two frames of the gantry frame 31, and the transmission assembly 33 (taking the transmission assembly 33 as an example, the same below) includes:

[0033] The upper transmission wheel 331 and the lower transmission wheel 332 are respectively arranged on the upper and lower parts of one side of the gantry 31 through the rotating shaft and the bearing seat;

[0034] The transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com