Method for optimizing crude oil dehydration parameters of pulsed electric field

A pulsed electric field, crude oil dehydration technology, applied in the direction of electricity/magnetic dehydration/demulsification, dehydration/demulsification regulation/control, petroleum industry, etc., can solve the problem that the purification effect cannot be fully guaranteed, the construction or maintenance of the electric field is difficult, and the parameters are adapted. Insufficient performance and other problems, to achieve the effect of narrowing the scope of parameter tuning, improving practicability and accuracy, and narrowing the scope of parameter tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

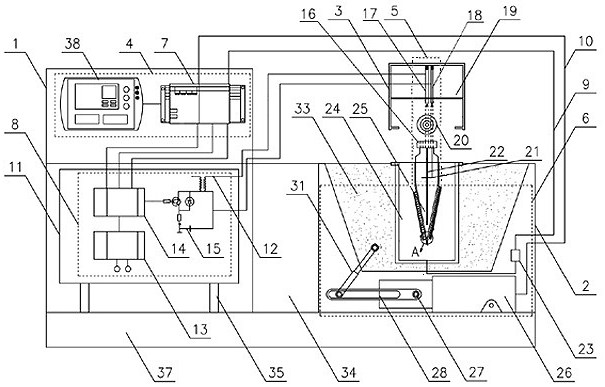

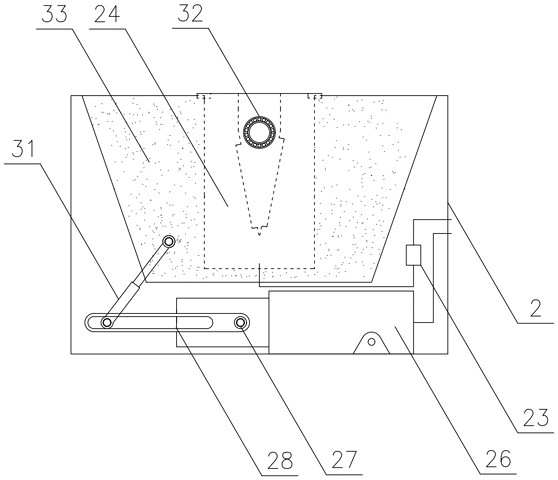

[0111] The present invention will be further described below with reference to the drawings:

[0112] This method of optimizing pulse electric field crude oil dehydration parameters is carried out using a pulsed electric field crude oil dehydration test device.

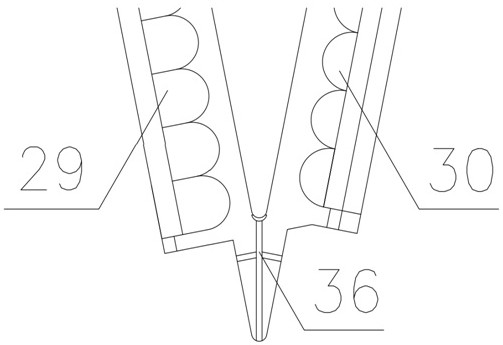

[0113] Combine Figure 1 - Figure 4 As shown, this pulse electric field crude oil dehydration test device mainly includes a control box 1, a heating tank 2, and an electrode box 3, a core partial pulse power supply system consisting of a control circuit adjustment module 4 in the control box 1, within the electrode box 3 The electric field build module 5, the oscillation temperature control and the water level monitoring module 6 in the heating tank 2 filled with the glass fiber insulation material 33. The control circuit adjustment module 4 leads the electric field control circuit 8, the heating control circuit 9, and the oscillation control circuit 10 from the PLC program controller 7, respectively. The electric field co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com