A Method for Optimizing Crude Oil Dehydration Parameters in Pulse Electric Field

A pulsed electric field and crude oil dehydration technology, which is applied in the fields of electric/magnetic dehydration/emulsification, electric digital data processing, dehydration/emulsification adjustment/control, etc., can solve the problems that the purification effect cannot be fully guaranteed, electric field construction or maintenance is difficult, Problems such as poor adaptability of parameters to achieve the effect of narrowing the scope of parameter tuning, improving practicability and accuracy, and reducing the scope of parameter tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] Below in conjunction with accompanying drawing, the present invention will be further described:

[0112] The method for optimizing the parameters of pulse electric field crude oil dehydration is carried out by using a pulse electric field crude oil dehydration test device.

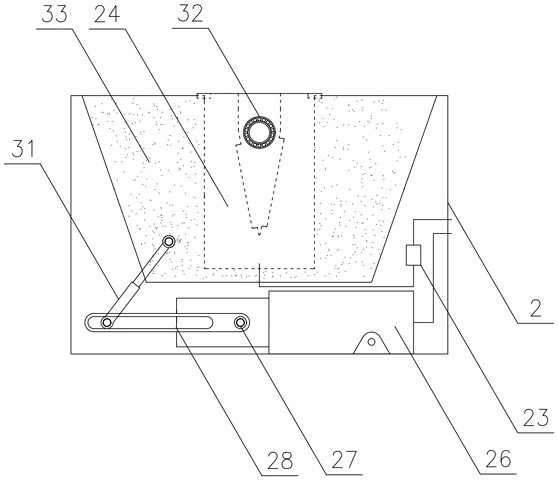

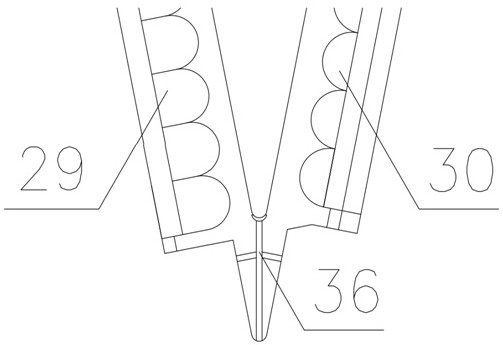

[0113] to combine Figure 1-Figure 4 As shown, this pulse electric field crude oil dehydration test device mainly includes three major components: the control box 1, the heating box 2 and the electrode box 3. The core part of the pulse power supply system is controlled by the control circuit in the control box 1. The electric field construction module 5, the oscillation temperature control and water level monitoring module 6 in the heating box 2 filled with glass fiber insulation material 33 constitute. The control circuit adjustment module 4 respectively leads out the electric field control circuit 8 , the heating control circuit 9 and the oscillation control circuit 10 from the PLC program contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com