Foundation pit supporting equipment for geotechnical engineering

A technology for foundation pit support and geotechnical engineering, applied in mining equipment, infrastructure engineering, earthwork drilling and mining, etc., can solve problems such as uneven mortar circulation, port damage, edge collapse, and cavity leakage, and achieve Guarantee the strength of support reinforcement, avoid bruising and edge collapse, and improve the effect of grouting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

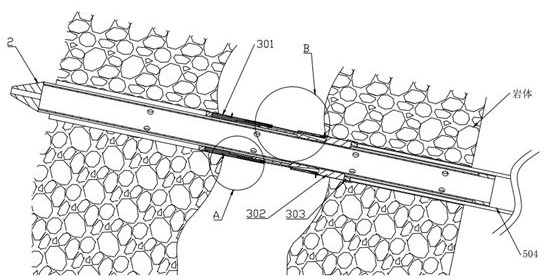

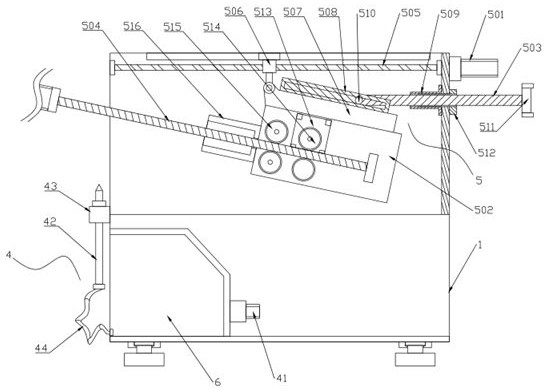

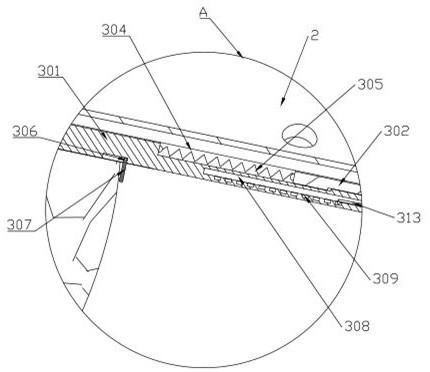

[0025] Such as Figure 1 to Figure 6 As shown, a foundation pit support equipment for geotechnical engineering includes a trolley 1, an anchor rod 2, a partition 3, a grouting mechanism 4, and an adjustment mechanism 5. A grout storage chamber 6 is arranged inside the trolley 1, The grouting mechanism 4 is installed on the grout storage chamber 6, and is used for injecting mortar into the rock mass drilling, and the adjusting mechanism 5 is installed in the trolley 1, and is used for adjusting the entry angle of the bolt 2, The partition 3 is sheathed on the anchor rod 2, and is used to prevent the slurry from spreading in the cracks of rock faults.

[0026] In this embodiment, the reinforcing grout used is a fluid mortar, and an accelerator and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com