Reinforcing method for wood structure decayed tenon-and-mortise joint

A wood structure, tenon and mortise technology, applied in building construction, construction, building maintenance and other directions, to achieve good reinforcement effect, good use effect, and improve the effect of stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

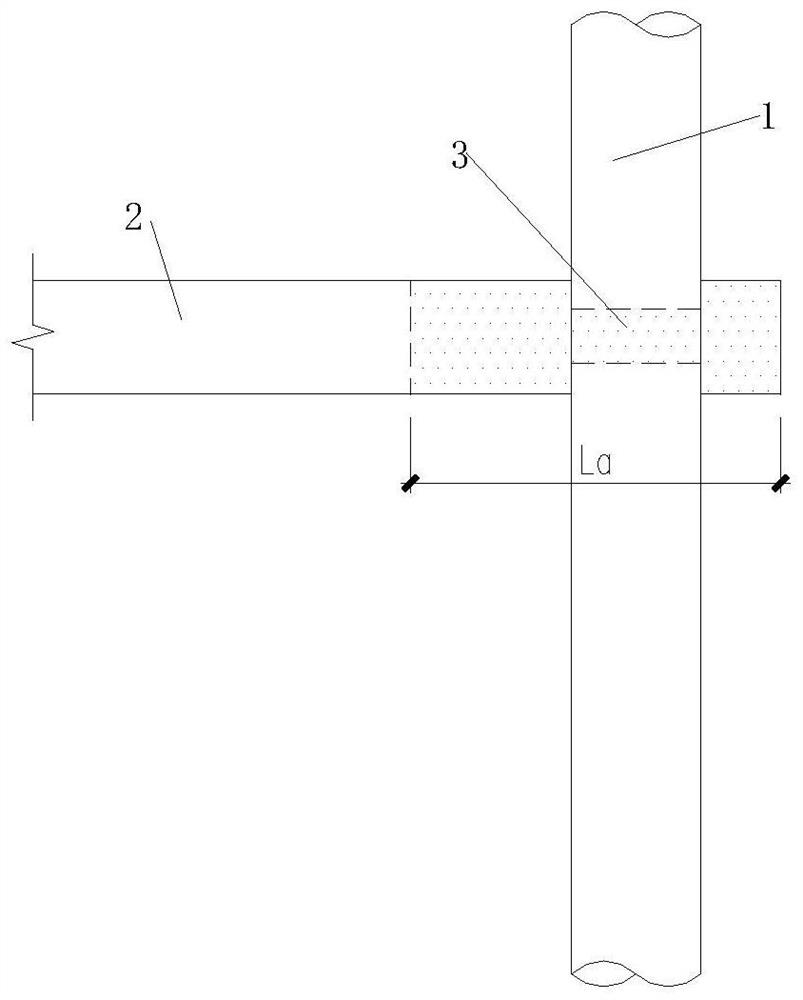

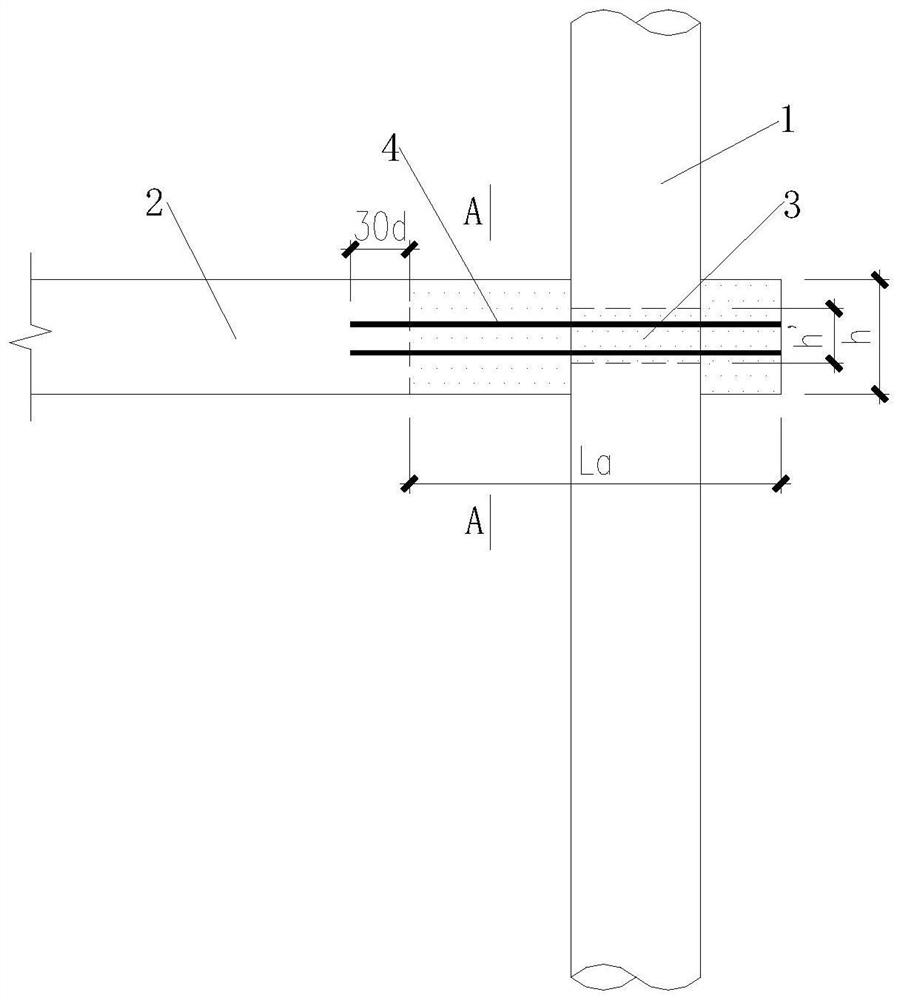

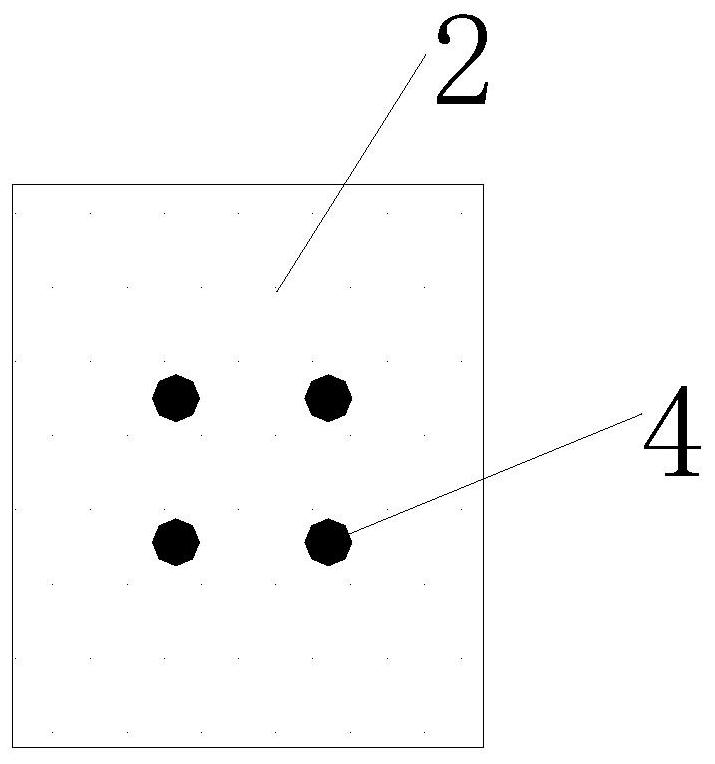

[0035] Such as Figure 1 to Figure 5 As shown, a method for reinforcing decayed mortise and tenon joints of a wooden structure of the present invention comprises the following steps:

[0036] Step 1. Determine the length of the decayed mortise and tenon area of the wooden structure;

[0037] In this embodiment, in step 1, the stress wave distribution of the decayed tenon and tenon area of the wooden structure obtained by tapping or micro-drilling resistance instrument is measured by using the wood stress wave measuring instrument, and then the length of the decayed tenon and tenon area of the wooden structure is determined.

[0038] Step 2, determine the equivalent cross-sectional area of the shape memory alloy:

[0039] When the cross-sectional area of wooden beam 2 is rectangular, the net section resistance moment of wooden beam 2 According to the formula 1.2W nw f nw =W ns f ns , to calculate the equivalent cross-sectional area of the shape memory alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com