Sidetracking well suspension-free releasing well cementation and completion device

A sidetracking and suspension-free technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of uncontrollable return height of annular cement slurry, failure of normal oil casing construction, tie-back Solve problems such as sealing uncertainty, achieve the effects of reducing wellbore leakage points, ensuring wellbore integrity and sealing, and simplifying construction procedures and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

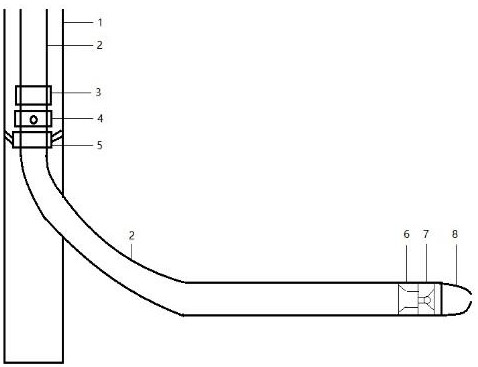

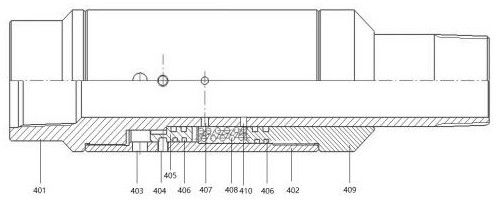

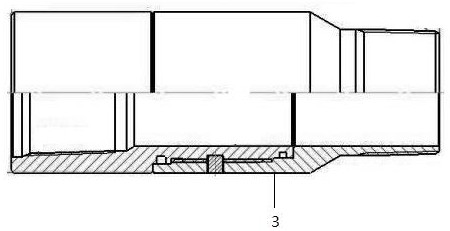

[0030] Such as figure 1 with image 3 As shown, the present invention provides a suspension-free sidetracking well cementing and completion device, which includes a sidetracking casing 2, a buckle and throwing hand 3 arranged inside the sidetracking casing 2, and a reverse circulation valve that can be automatically opened and closed. 4. The one-way cup packer 5 is threadedly connected with the casing 2 of the sidetracking well; above the one-way cup packer 5, there is an automatic switchable reverse circulation valve 4, and the automatic switchable reverse circulation valve 4 The upper part of the cementing cement is provided with a reverse buckle 3; the one-way cup packer 5 can bear a certain upper pressure but allows the annular liquid to go upward; in order to prevent the cementing cement from going up too high, the reverse buckle 3 is solidified and causes The upper pipe string cannot be pulled out. After the cementing is completed, the reverse circulation valve 4 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com