Flywheel gear ring structure with split type gear ring at fixed points and application method

A flywheel ring gear, split-type technology, applied in the direction of engine starting, engine motor starting, starting device with mechanical power storage, etc., can solve the problem of inability to service without special equipment, shortened life of flywheel ring gear, difficulty in service and maintenance Large and other problems, to achieve the effect of preventing tooth punching, improving service life and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

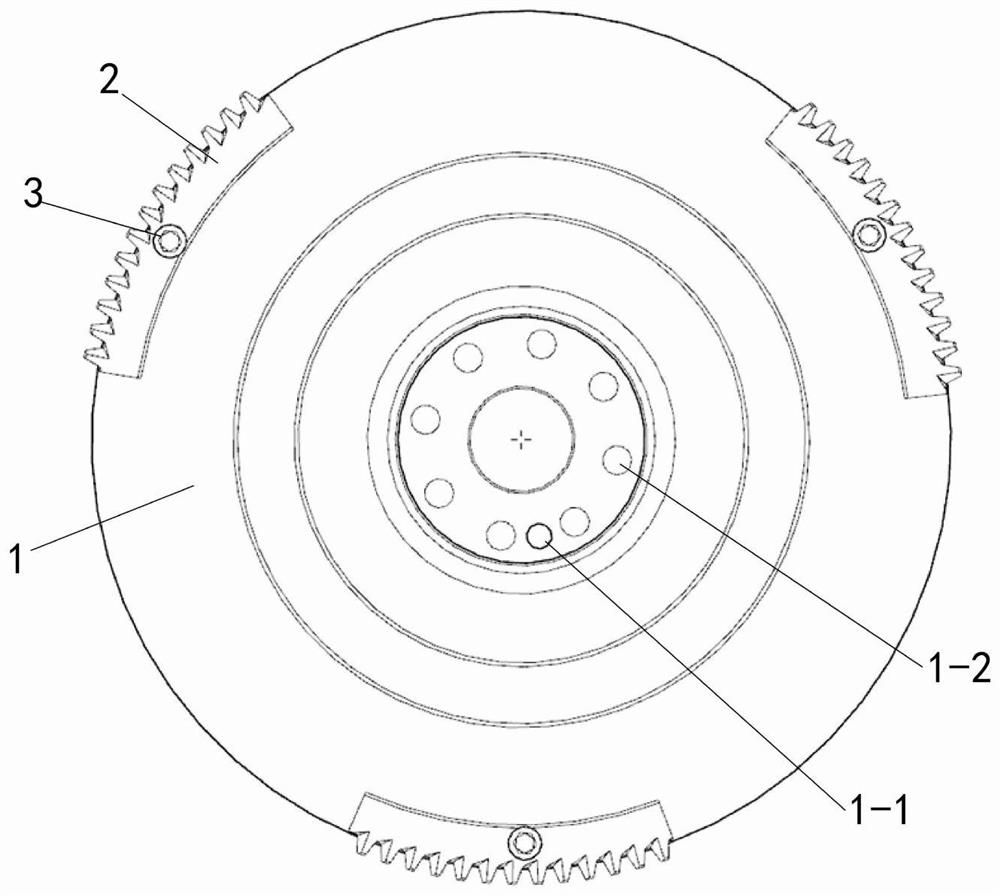

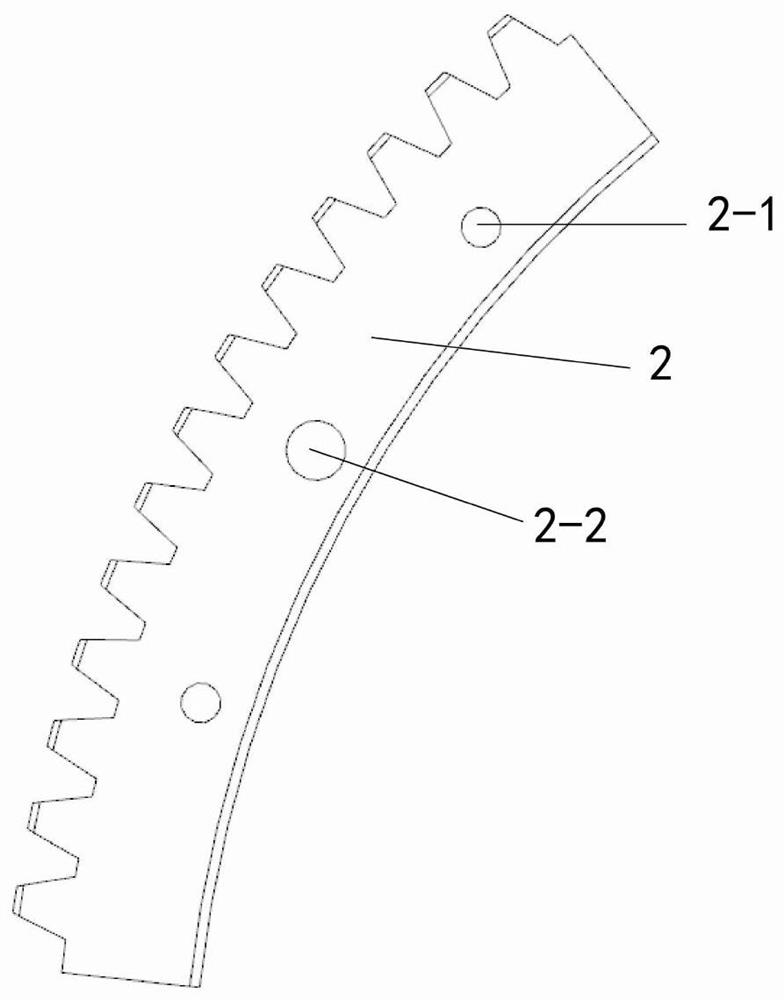

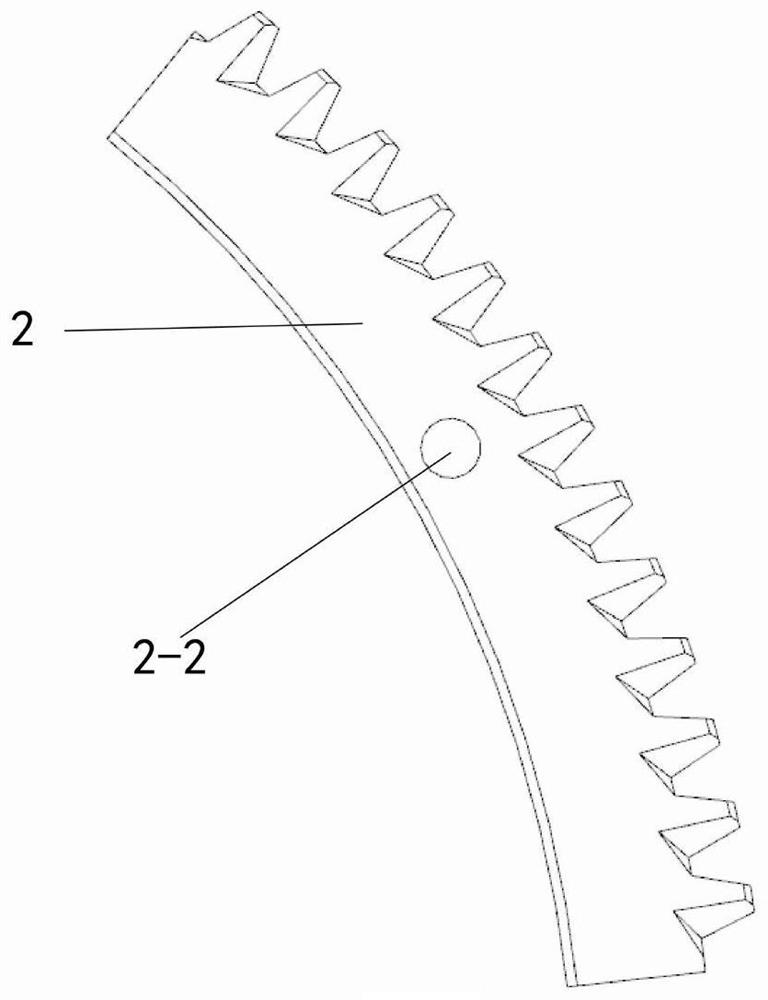

[0027] A fixed-point flywheel ring gear structure with a split ring gear, including a starter drive gear 5, a starter drive gear telescopic control system, a driven gear 4, and a flywheel 1. The flywheel 1 is detachable and uniformly distributed with a number of Split ring gear 2; this embodiment is provided with two split ring gears 2 or three split ring gears 2 for the type of engine. If there are two split ring gears, then It is distributed at 180 degrees, corresponding to a four-cylinder engine (such as an in-line plane four-stroke four-cylinder engine); if there are three split ring gears 2, the three split ring gears 2 are distributed at 120 degrees, It corresponds to a six-cylinder engine (such as an in-line six-cylinder four-stroke engine). This is mainly to ensure that one of the split ring gears 2 can mesh with the driven gear 4 after stopping. The split ring gear 2 in this embodiment may contain 10-15 teeth or preferably 12 teeth. When connecting, in this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com