Heat exchange tower heat pump cooling and heating system and control method

A technology of heating system and heat exchange tower, applied in space heating and ventilation, heating mode, air conditioning system, etc., can solve the problems of screw machine cold and heat unable to meet the requirements, solution concentration control and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

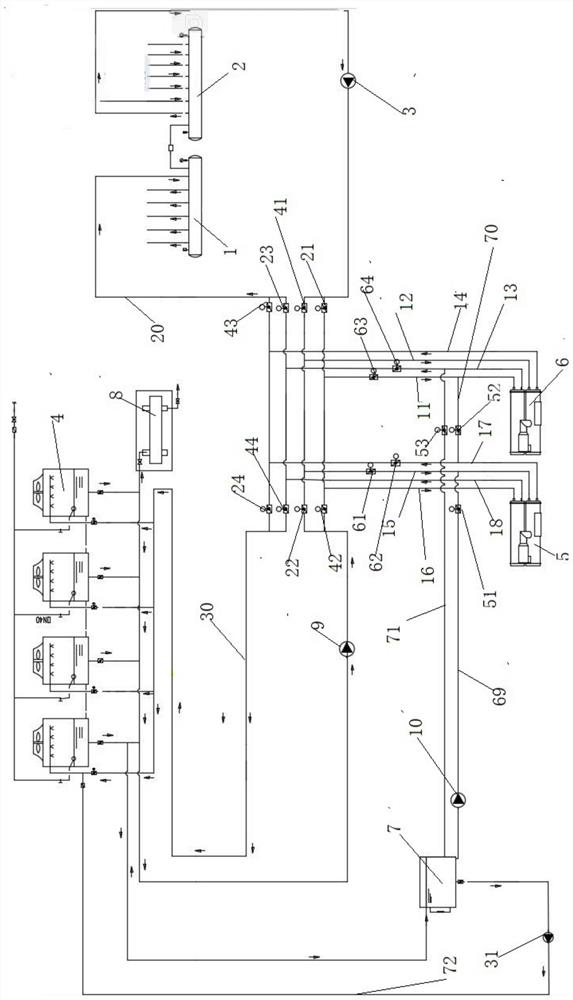

[0025] In the cooling mode, the chilled water at 12°C returns to the water collector 2 from the end of the user, and then flows into the inlet of the user water pump 33 . A-1 valve 21, A-2 valve 22, A-3 valve 23, A-4 valve 24, D-1 valve 61, D-2 valve 62, D-3 valve 63, D-4 valve 64 open, B -1 valve 41, B-2 valve 42, B-3 valve 43, B-4 valve 44, C-1 valve 51, C-2 valve 52, C-3 valve 53, the water in the water collector 2 enters the first In the first evaporator of a centrifugal heat pump unit and the second evaporator of the second centrifugal heat pump unit, after the temperature of the chilled water is reduced to 7°C, it enters the water separator 1 through the A-3 valve 23, and the temperature in the water separator 1 is 7°C The chilled water is supplied to users through pipelines, and the cooling water at 30°C flows out from the bottom of multiple heat exchange towers 4, and then passes through the tower water pump 9. After the cooling water is boosted, it passes through the ...

Embodiment 2

[0027] In the heating mode, the 40°C chilled water returns to the water collector 2 from the user end, and then flows into the inlet of the user water pump 33, and the -7°C antifreeze in the heat exchange tower 4 enters the second evaporator, B- 1 valve 41, B-2 valve 42, B-3 valve 43, B-4 valve 44, C-1 valve 51, C-2 valve 52, C-3 valve 53 open, A-1 valve 21, A-2 Valve 22, A-3 valve 23, A-4 valve 24, D-1 valve 61, D-2 valve 62, D-3 valve 63, D-4 valve 64 are closed, chilled water is boosted by user water pump 33 and then passed through B-1 valve 41, and then enter the second condenser of the second centrifugal heat pump unit. After the hot water temperature rises to 45°C, it enters the water separator 1 through the B-3 valve 43, and the heat of 45°C in the water separator 1 Water is supplied to users through pipelines, and at the same time, -7°C antifreeze flows out from the bottom of multiple heat exchange towers 4, and then flows into the tower water pump 9 inlet. After the a...

Embodiment 3

[0031] On the basis of Example 2, when the solution concentration detection device 8 detects that the solution concentration is lower than the set value, the outlet valve of the solution tank 7 is opened, the second solution pump 31 is opened, and the dilute solution at 20°C is pressurized and then passed through the check The valve flows into one of the heat exchange towers 4, the water in the solution evaporates into the air, the solution concentration increases, and then flows back into the solution tank 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com