Hot air knife

An air knife and hot air technology, applied in the field of machinery, can solve problems such as increasing power consumption, increasing electric heating power, and heat energy loss, and achieves the effects of improving thermal efficiency, increasing flow rate, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

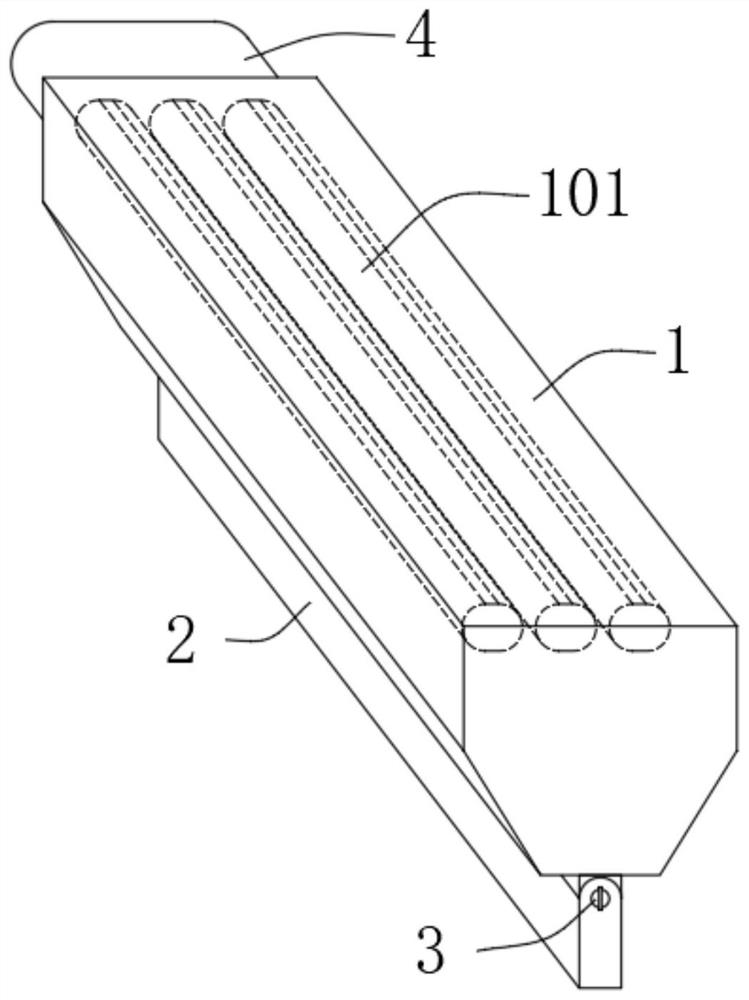

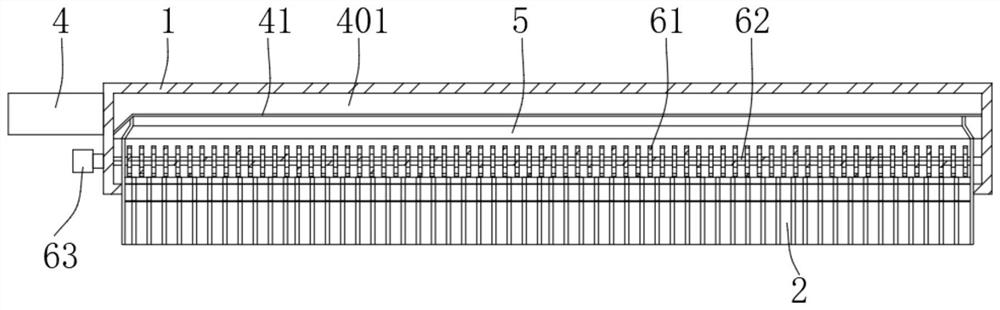

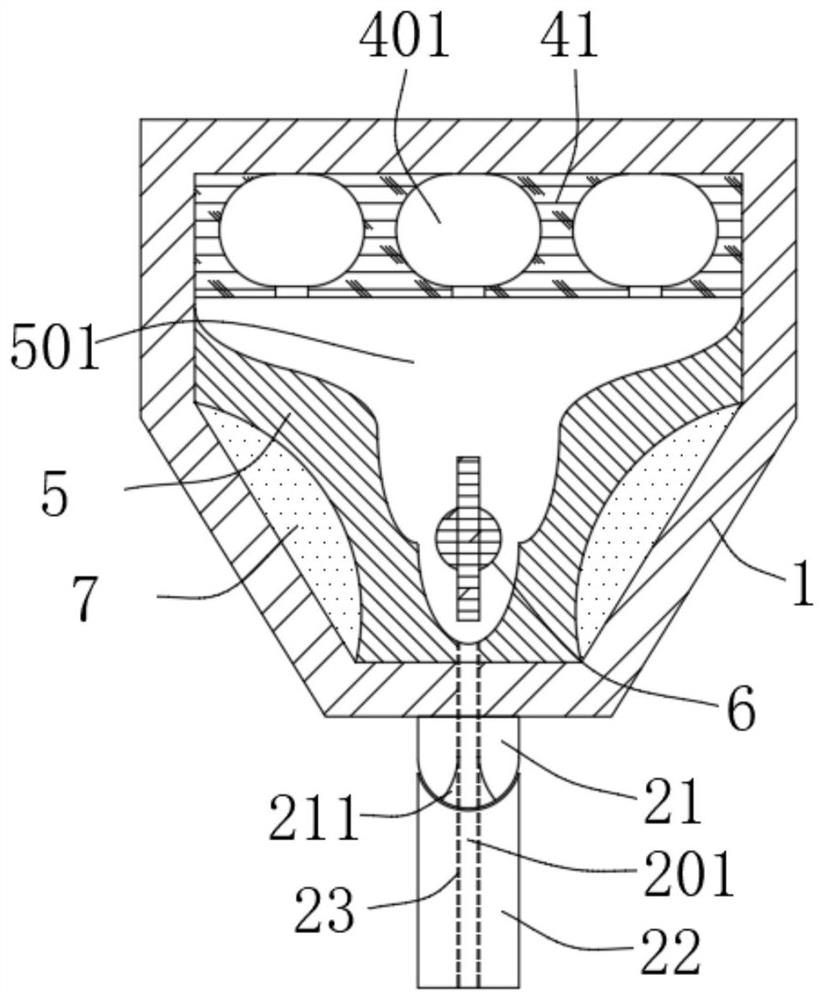

[0021] to combine Figure 1-3 As shown, the hot air knife includes an air knife shell 1 and an air outlet plate 2 arranged at the bottom of the air knife shell 1. One end of the air knife shell 1 is fixedly provided with an air inlet pipe 4 connected to an external air source. A heating mechanism 6 for heating the air flow is arranged on the inside corresponding to the top of the air outlet plate 2 , and the heating mechanism 6 is arranged along the length direction of the air knife housing 1 .

[0022] Among them, the air knife shell 1, the air outlet plate 2 and the air inlet pipe 4 can all be made of metal alloy materials. The cross section of the air knife shell 1 is an inverted trapezoidal structure, and the air outlet plate 2 is arranged at the bottom of the air knife shell 1, which is beneficial to the compressed air flow. The air outlet plate 2 leads out, and the heating mechanism 6 can adopt an electric heating wire, so that the airflow is heated when passing through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com