Method and device for changing the production of a flat film machine from an input product to a subsequent product

A product, flat film technology, applied in the direction of flat products, applications, program control, etc., can solve the problems of high cost, non-existent conversion mechanism reproducibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

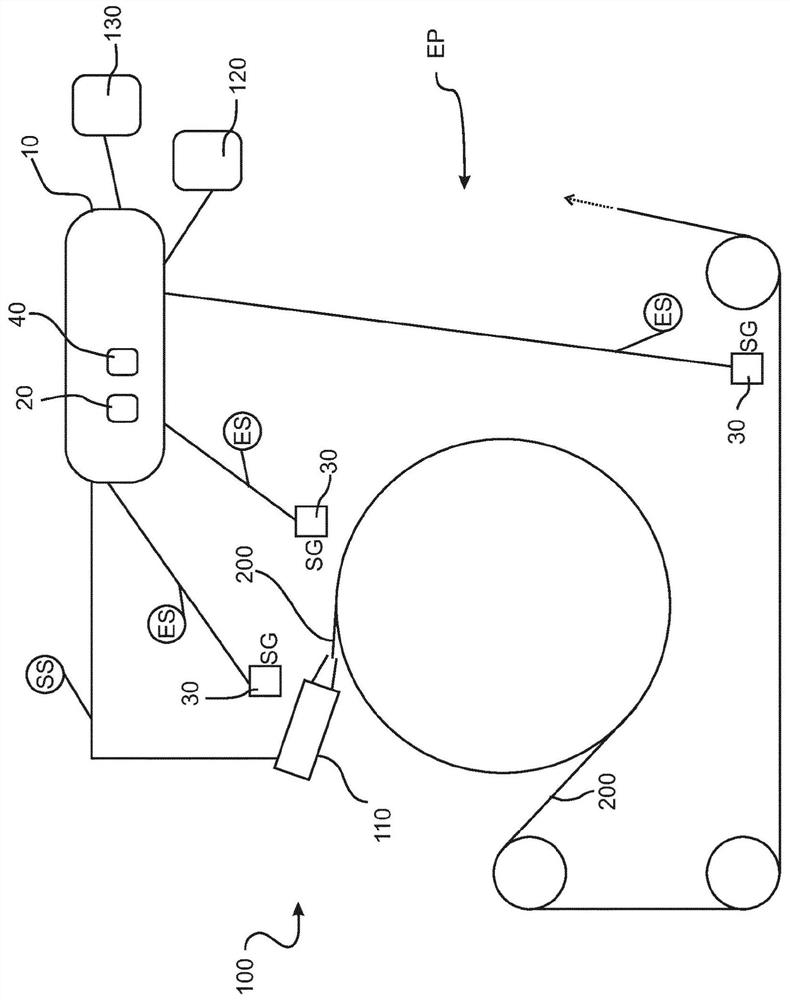

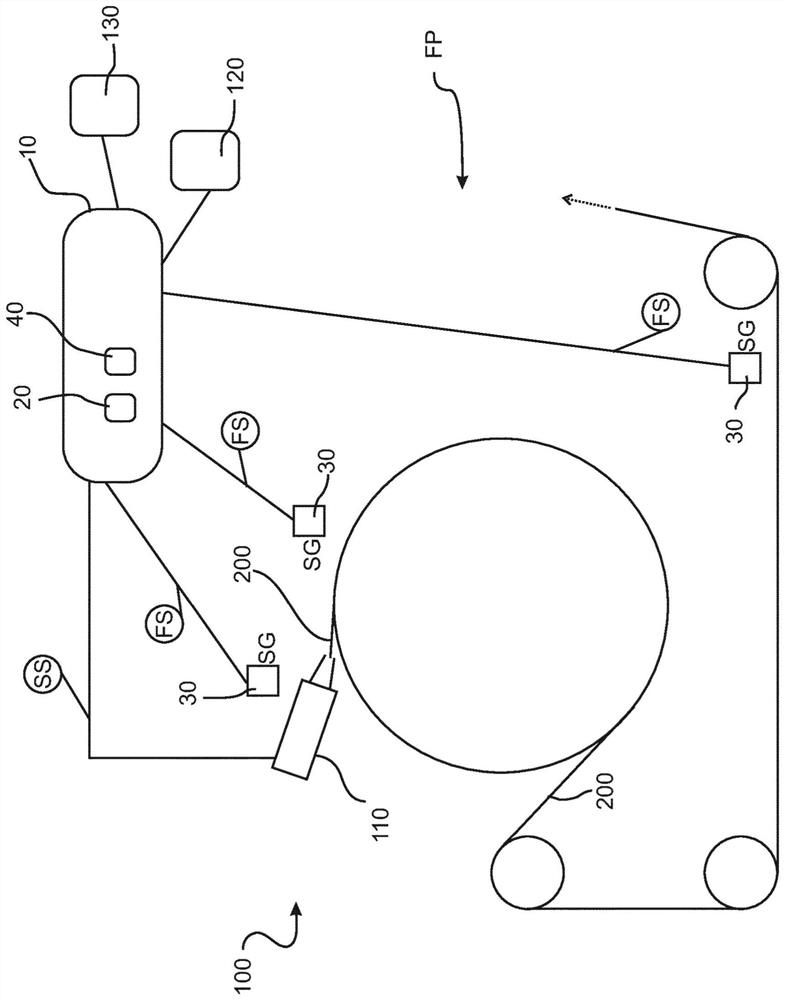

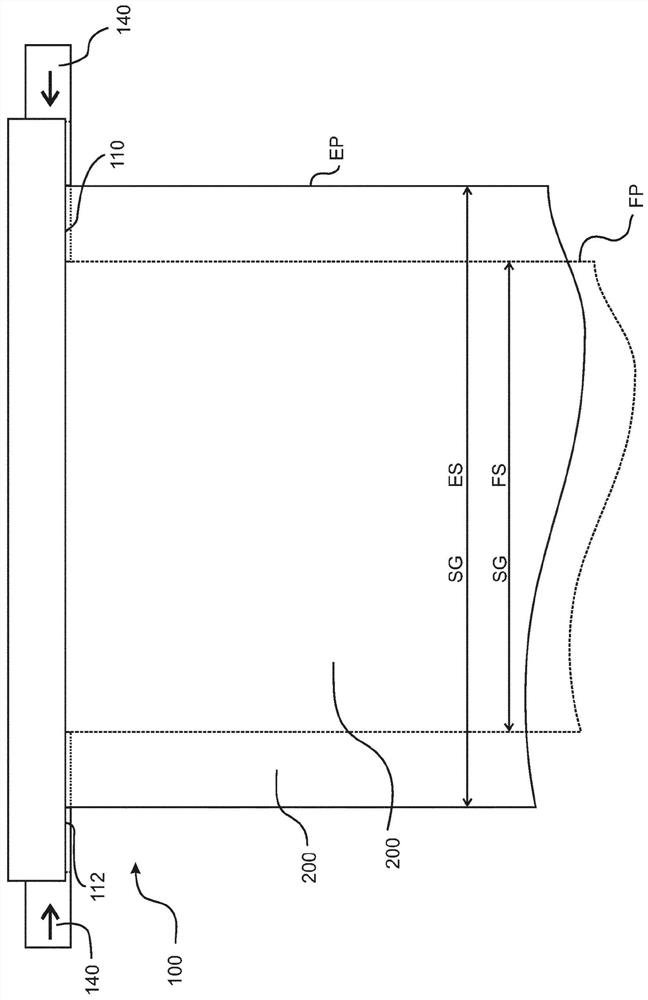

[0033] figure 1 and figure 2 It is schematically shown how the film flattener 100 may be constructed. Via the nozzle arrangement 100 the film web 200 can be discharged in liquid state and applied to a large cooling roll which is not shown in detail. The film web 200 now continues over a plurality of roller-like rolls and can be reprocessed, cut and / or wound.

[0034] here, in figure 1 The production of the initial product EP is shown in , in which case, for example, a defined clear width and / or a defined outlet width of the nozzle arrangement 110 is specified. If it is now desired to switch to the follow-on product FP, then according to this embodiment the setting variable SG is recorded at one or more points by the changing device 10 as an initial set value ES. Here, the determination module 30 in the lower right corner can be used for thickness determination, for example. The central determination module can, for example, record a control variable SG in the form of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com