Honey-flavor white tea making equipment and use method thereof

A technology for honey-flavored white tea, which is applied in the field of production equipment for honey-flavored white tea, which can solve the problems of improving white tea, unstable quality, and limited efficiency, and achieve the effect of improving withering effect, shortening storage time, and bright orange soup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

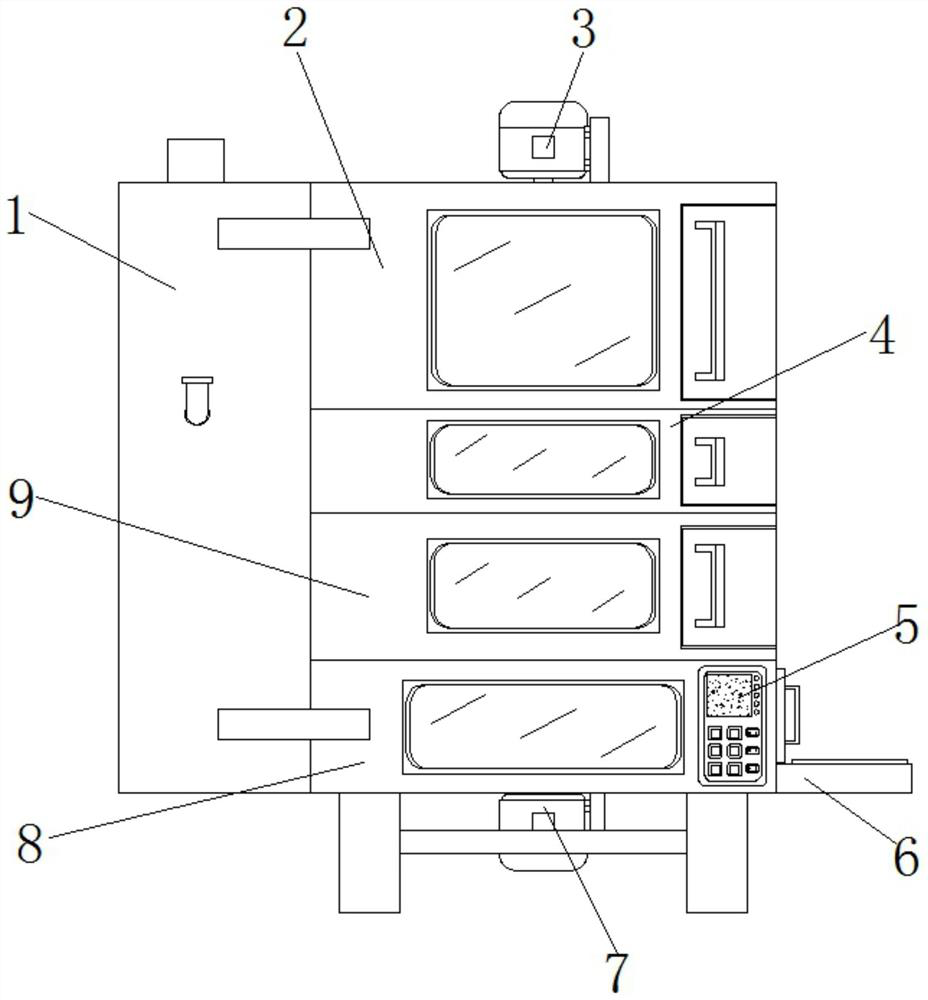

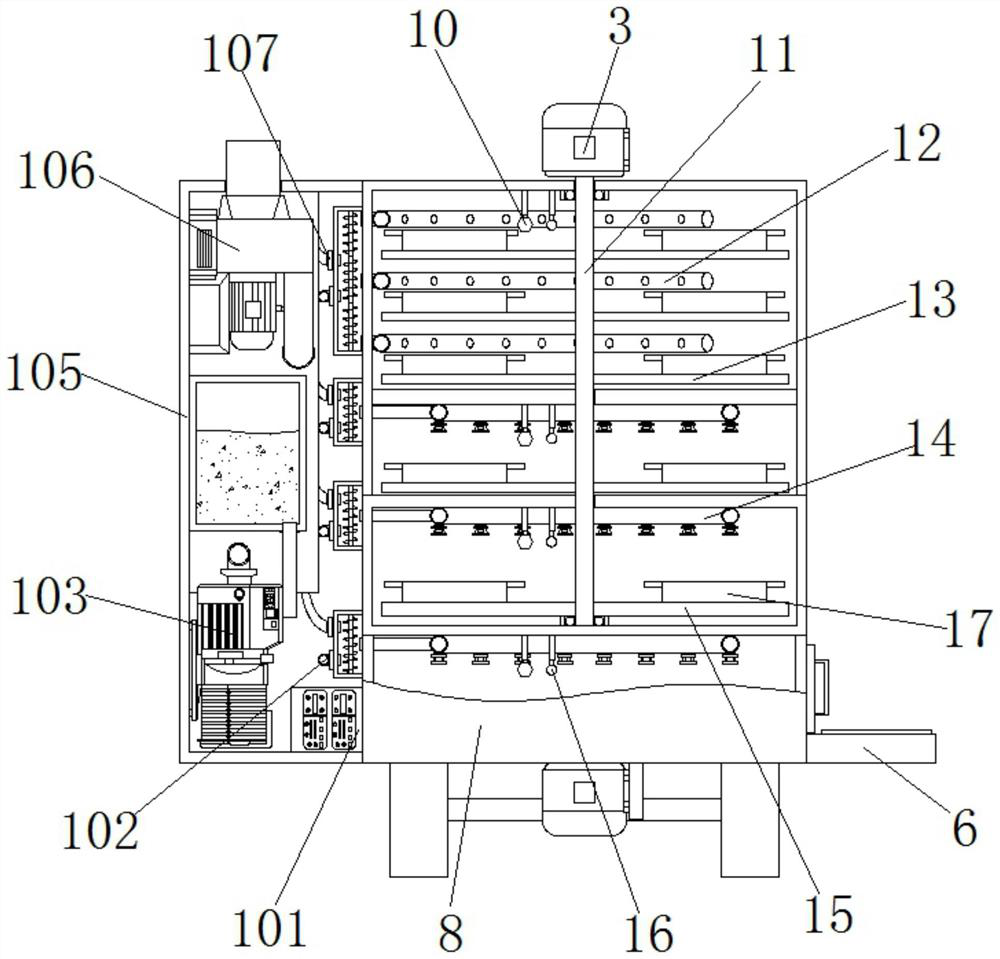

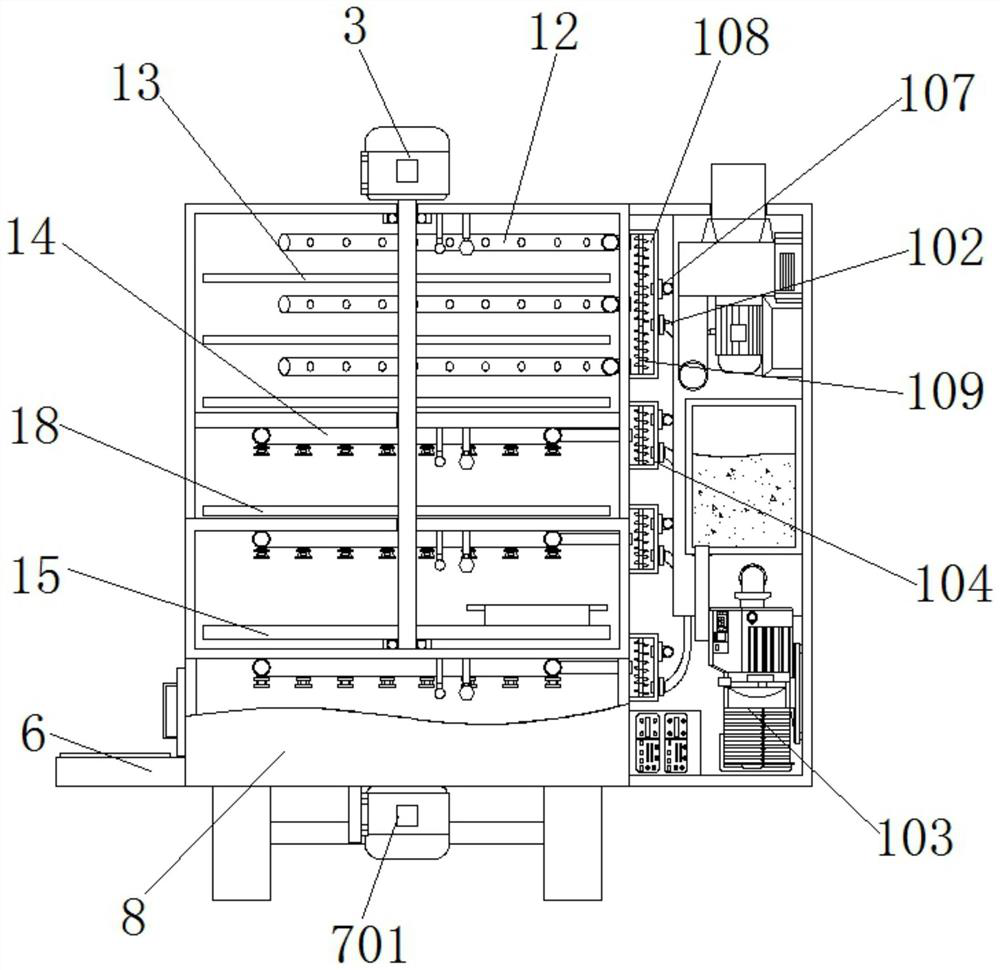

[0041] Example 1, such as figure 1 , 4 As shown in and 5, when starting to wither the fresh leaves of white tea at room temperature, open the door of the high-temperature withering bin 9, and place the tray 17 on the top of the placement board 6, so that the auxiliary slide bar on the top of the placement board 6 is locked. into the auxiliary chute at the bottom of the storage tray 17, so that a group of draw-in slots 21 on the storage tray 17 face the inside of the room temperature withering bin 8, and then control the first electric lifting rod 19 to extend to the longest through the control panel 5, Then control the second electric lifting rod 23 to rise until the L-shaped bayonet pin 20 at the output end of the first electric lifting rod 19 snaps into the draw-in groove 21 outside the storage tray 17, then utilize the first electric lifting rod 19 to place the storage tray 17 is pulled into the room temperature withering bin 8, so that the storage tray 17 moves to the top...

Embodiment 2

[0042] Example 2, such as Figure 1-6 As shown, when the fresh leaves of white tea are started to be further processed, the fresh leaves of white tea are first subjected to high-temperature withering treatment, the holding tray 17 is taken out from the inside of the room temperature withering bin 8, the door of the high-temperature withering bin 9 is opened, and the container is then The object tray 17 is placed on the top of the first disc 15 in turn, and then the door is closed, and the air with a relative humidity of 45-60% and a temperature of 45-50°C is blown into the interior of the high-temperature withering chamber 9 by using the humidity and heat adjustment assembly 1, and the high-temperature withering In one minute, the temperature of the withered leaves is rapidly raised to 40-42°C, and the fresh leaves are immersed in water, and then the next process can be entered. During the process, the cooperation of the first servo motor 3 and the rotating rod 11 is used to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com