Bioactive glass/biomimetic functional polypeptide complex, preparation method and application

A technology of bioactive glass and biomimetic function, which is applied in the direction of drug combination, pharmaceutical formula, liquid delivery, etc., can solve the problems of lack of remineralization calcium and phosphorus sources, inability to induce dental pulp cell regeneration, etc., to promote dentin repair, promote Proliferation Migration and Differentiation, Effects of Design Science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present embodiment provides the method that adopts sol-gel method to prepare mesoporous bioactive glass, specifically:

[0043] Premix 30mL deionized water and 120mL nitric acid solution with a concentration of 2M, then add 3g of P123 surfactant to dissolve, adjust the pH value of the solution to below 1 with nitric acid, add 8.5g tetraethyl orthosilicate (TEOS), 0.98 g triethyl phosphate (TEP) and 5.94 g calcium nitrate, stirred at 60°C for 48 hours, dried in an oven at 100°C for 12h, and the obtained powder was calcined in a muffle furnace at 600°C for 6h, with a heating rate of 1°C / min, the obtained product is mesoporous bioactive glass.

Embodiment 2

[0045] This embodiment provides a preparation method of bioactive glass / biomimetic functional polypeptide complex, specifically:

[0046] Add 50 mg of mesoporous bioactive glass to 10 mL of PBS buffer, ultrasonically disperse for 10 minutes, add 15 mg of QP5 polypeptide (its amino acid sequence is shown in SEQ ID NO.1), stir magnetically at 4°C for 24 h, centrifuge, and wash the precipitate with PBS Three times, vacuum freeze-dry. The mesoporous bioactive glass described in this example was prepared according to the method of Example 1.

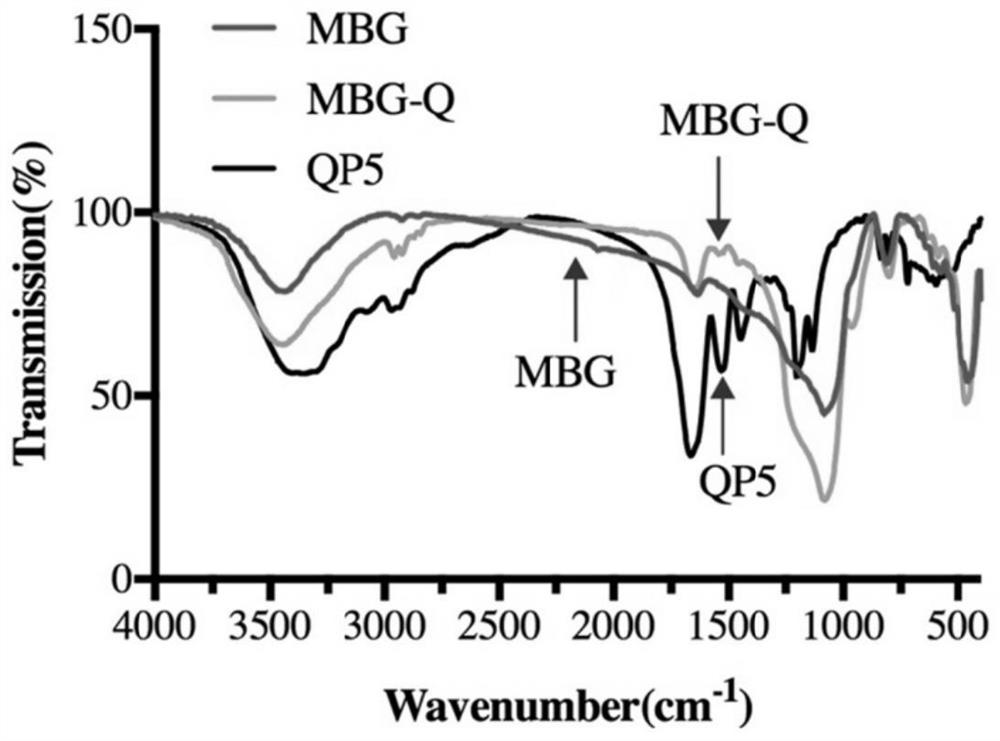

[0047] The bioactive glass / biomimetic functional polypeptide complex prepared in this example is subjected to infrared analysis, and its infrared spectrum is as attached figure 1 , where MBG means bioactive glass, QP5 means biomimetic functional polypeptide, and MBG-Q means bioactive glass / biomimetic functional polypeptide complex. The results showed that, compared with the bioactive glass not loaded with polypeptide, the bioactive glass / bi...

Embodiment 3

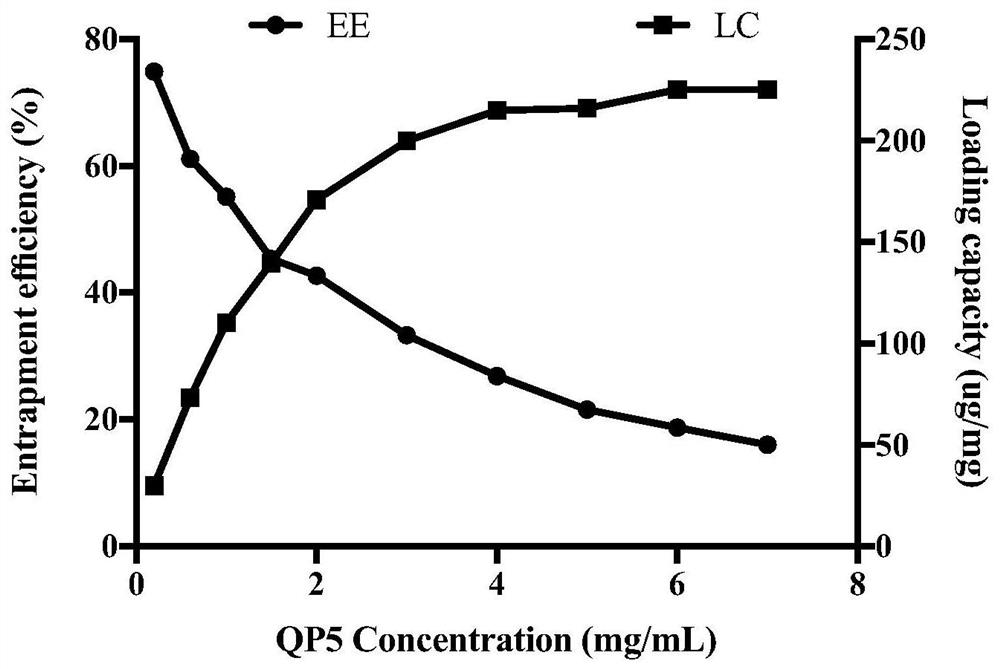

[0049] This example provides an investigation of different dosage ratios of bioactive glass / biomimetic functional polypeptide complexes, specifically:

[0050] Add 50mg of mesoporous bioactive glass to 10mL of PBS buffer, ultrasonically disperse it for 10 minutes, then add QP5 polypeptides of different quality to suspend 50mg of bioactive glass powder in 10mL of different concentrations (0.2-7.0mg / mL) In the peptide solution, stir magnetically at 4°C for 24 hours, centrifuge, collect the supernatant, measure the concentration of unloaded free peptide in the supernatant with a UV-visible spectrophotometer, and calculate the concentration of the peptide encapsulated into the bioactive glass carrier. The encapsulation efficiency of the polypeptide and the drug loading capacity of the complex.

[0051] The encapsulation efficiency calculation formula is as follows: EE=(C0-C1) / C0×100%;

[0052] Among them, EE represents the encapsulation efficiency, CO represents the total concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com